Method for removing and recycling phosphorus from sewage based on aerobic granular sludge

A technology of aerobic granular sludge and granular sludge, applied in water/sludge/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve problems such as high cost, large land occupation, and complicated operation , to achieve the effect of saving medicine costs, simplifying complexity, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

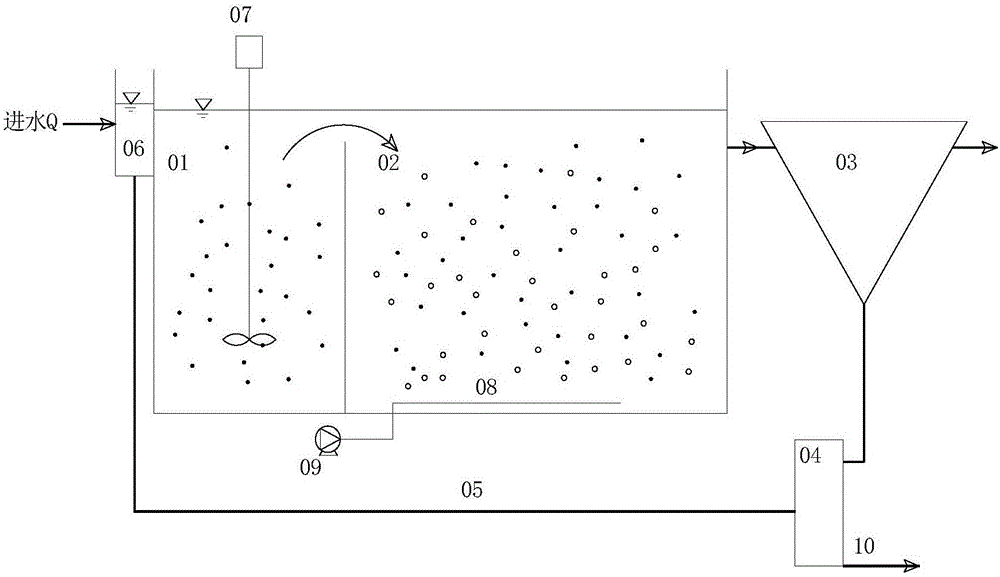

[0015] Embodiment 1: the removal and recovery system of sewage phosphorus based on aerobic granular sludge, such as figure 1 As shown, it mainly includes four parts: anaerobic-aerobic-sedimentation-granular sludge selection, and adopts continuous operation; influent mixing zone 06 is adjacent to anaerobic zone 01, anaerobic zone 01 is adjacent to aerobic zone 02, and aerobic zone 02 is connected to the sedimentation tank 03, and the sedimentation tank 03 is connected to the granular sludge selector 04, and the granular sludge selector 04 is connected to the influent mixing zone 06 through the granular sludge return system 05; among them, the agitator 07 is set in the anaerobic zone 01 , the aerobic zone 01 is equipped with an aeration system 08, the aeration system 08 is connected with the blower 09, and the granular sludge selector 04 is provided with a granular sludge discharge port 10.

[0016] as attached figure 1 , the anaerobic zone 01 maintains an anaerobic state, and ...

Embodiment 2

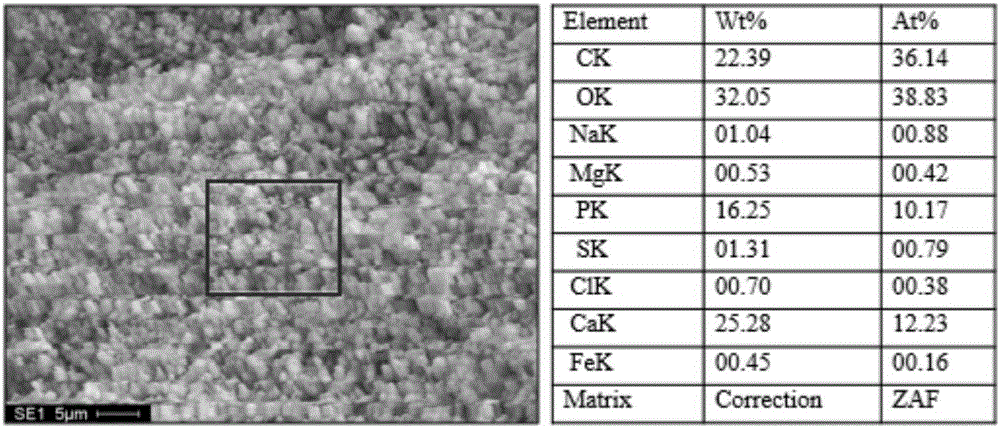

[0018] Example 2: The method used in this example is as in Example 1, wherein the nutrient ratio C:N:P in the influent water is 100:20:4, the hydraulic retention time of the anaerobic zone 01 is controlled for 1 to 3 hours, and the aerobic zone 02 is controlled. The hydraulic retention time is 3-6 hours, and the hydraulic retention time of granular sludge selection zone 04 is 0.2-1 hour; the pH of anaerobic zone 01 and aerobic zone 02 is controlled to be 7.5-7.8. At this time, the system excludes the high concentration of phosphorus and calcium in the granular sludge, such as image 3 As shown, the inside of the particle is denser, cocci and brevibacteria are dominant, the phosphorus content of the sludge is 16.25%, and the calcium content is 25.28%.

Embodiment 3

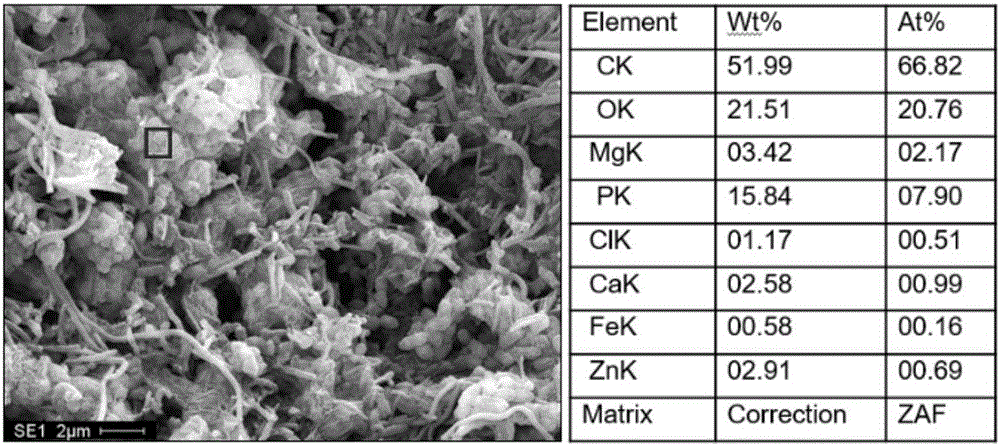

[0019] Example 3: The method used in this example is as in Example 1. Granular sludge and flocculent sludge are inoculated into the reactor according to the TSS ratio of 2:1, and the MLSS is 3500 mg / L; the nutrient ratio in the influent is C: N: P is 100:10:4, the hydraulic retention time of control anaerobic zone 01 is 1-3 hours, the hydraulic retention time of aerobic zone 02 is 3-6 hours, and the hydraulic retention time of granular sludge selection zone 04 is 0.2-1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com