Energy-saving quick-start aerobic granular sludge reactor

An aerobic granular sludge, quick-start technology, applied in water/sludge/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve problems such as energy waste, reduce aeration volume, The effect of energy-saving operation start-up cycle and aeration volume saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

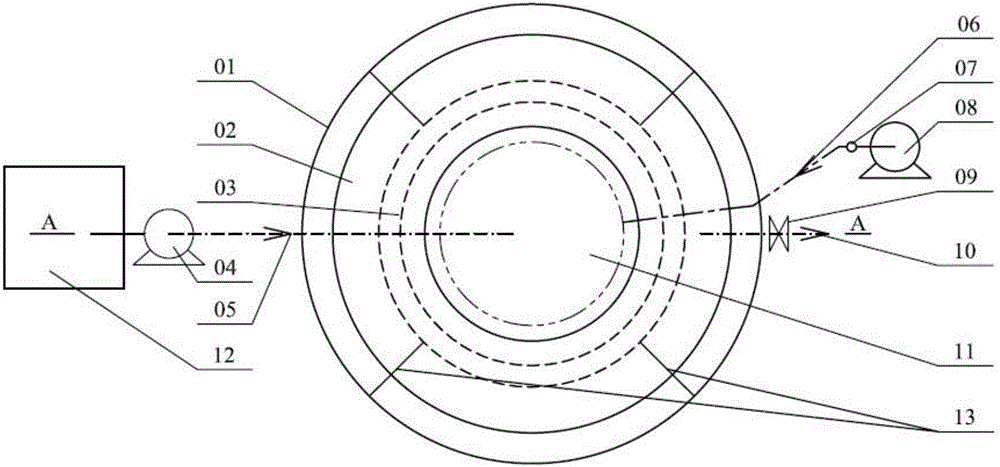

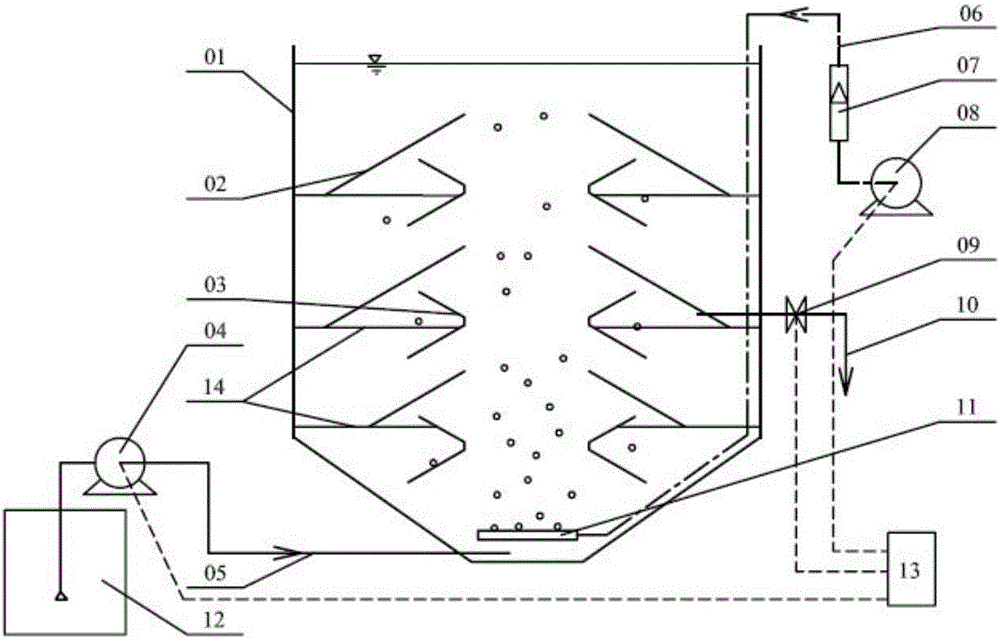

[0015] Example 1: The reactor used in this example is equipped with a multi-stage conical hydraulic circulation cover and an annular vortex flap, and the sequence batch type aerobic granular sludge reactor (AGS-SBER) with a height-to-diameter ratio of 0.8, that is, using Aerobic granular sludge reactor for sewage treatment in intermittent operation; as attached figure 1 , 2 Shown: The shape of the reactor is cylindrical, the height-to-diameter ratio of the reactor is 0.8, the effective height of the cylinder is 1.2m, and the diameter is 1.5m, 8.48m 3 ;The bottom of the reactor is a conical mud storage hopper, and a water inlet device is installed at the bottom of the conical mud storage hopper. When the water is fed, no aeration is performed and the inlet water is fully in contact with the sludge. The water inlet pipe 05 and the external water inlet pump 04 of the reactor connected, the water inflow time is controlled by the water inlet pump for 60 to 120 minutes; at the same...

Embodiment 2

[0017] Example 2: The reactor used in this example is equipped with a multi-stage conical hydraulic circulation cover and an annular vortex flap, and the sequence batch type aerobic granular sludge reactor (AGS-SBER) with a height-to-diameter ratio of 0.8, that is, using Aerobic granular sludge reactor for sewage treatment in intermittent operation; as attached figure 1 , 2 Shown: The shape of the reactor is cylindrical, the height-to-diameter ratio of the reactor is 0.8, the effective height of the cylinder is 1.2m, and the diameter is 1.5m, 8.48m 3;The bottom of the reactor is a conical mud storage hopper, and a water inlet device is installed at the bottom of the conical mud storage hopper. When the water is fed, no aeration is performed and the inlet water is fully in contact with the sludge. The water inlet pipe 05 and the external water inlet pump 04 of the reactor connected, the water inflow time is controlled by the water inlet pump for 10 to 60 minutes; at the same t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com