A device and method for removing ammonia nitrogen from anaerobic digestion fermentation broth

A technology for anaerobic digestion and fermentation broth, applied in chemical instruments and methods, separation methods, degassed water/sewage treatment, etc., can solve problems such as rare reports, and achieve long service life, strong controllability and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

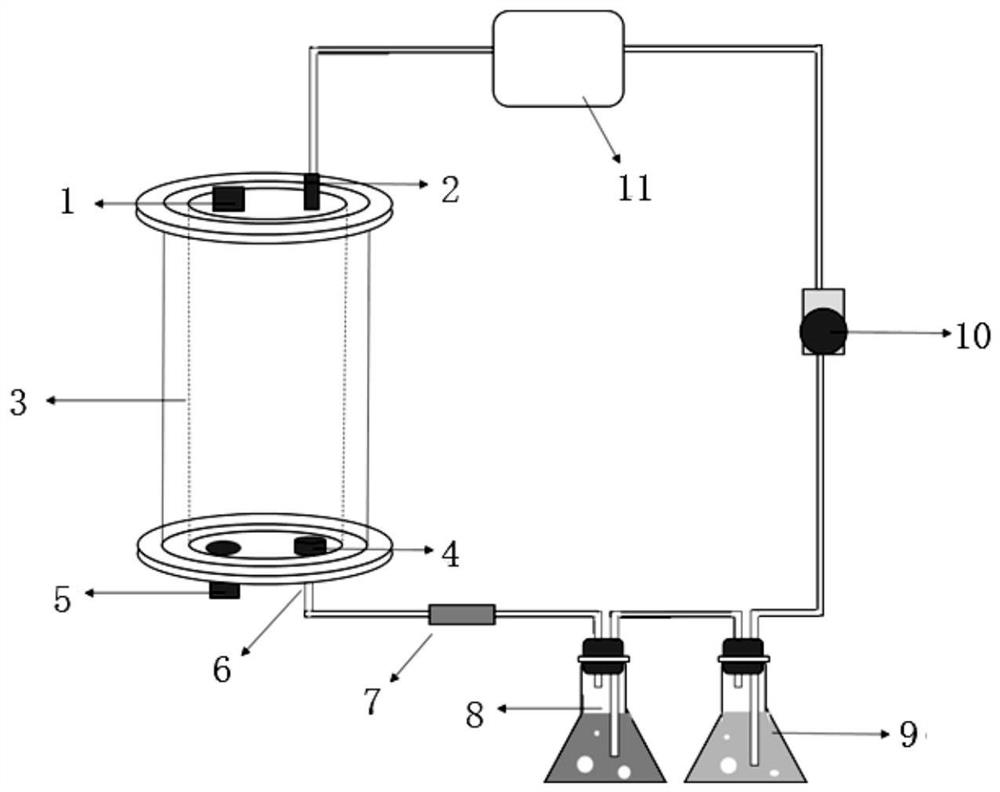

[0041] Such as figure 1 As shown, a device for removing ammonia nitrogen in anaerobic digestion fermentation liquid includes: a denitrification reaction tank, an ammonia trap and a gas circulation system, wherein: the denitrification reaction tank includes a stainless steel tank body and an electric heating jacket 3 , the ammonia trap includes a dilute sulfuric acid solution trap 8, a water trap 9, and the gas circulation system includes a gas flow meter 7, an air pump 10, an air bag 11 and a gas pipe connecting the entire passage.

[0042] Such as figure 1 Shown, in the described denitrification reaction tank:

[0043] The stainless steel tank body has inner and outer layers, and the electric heating jacket 3 is arranged in the interlayer of the inner and outer layers of the stainless steel tank body, and the electric heating jacket 3 is set and controlled by a temperature controller to control the temperature inside the stainless steel tank body. temperature.

[0044] Fur...

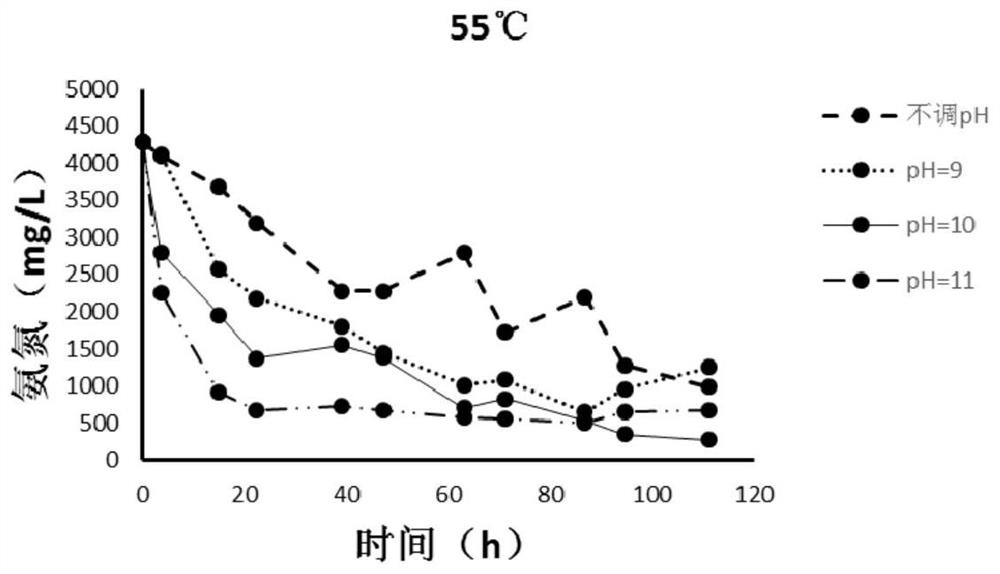

Embodiment 2

[0059] A method for removing ammonia nitrogen in anaerobic digestion fermentation liquid, including device connection and system air tightness inspection; gas circulation in the device under certain temperature conditions; absorption of ammonia nitrogen in the circulating gas; sulfuric acid solution in the ammonia trap Configuration; Calculation of nitrogen loss before and after denitrification of fermentation broth; Calculation of denitrification efficiency.

[0060] The specific operation steps include:

[0061] (1) Complete the configuration of the dilute sulfuric acid solution in the ammonia trap, place the prepared dilute sulfuric acid solution and deionized water in a corresponding airtight container and seal it;

[0062] (2) Fill the air bag in the channel with N 2 ;

[0063] (3) Complete the connection between the denitrification reaction tank, the ammonia trap and the components of the gas circulation system of the device, and conduct an air tightness inspection on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com