A method for recovering ammonia and water and preparing ammonia water in the production process of polyetheramine

A production process, polyetheramine technology, applied in the field of ammonia and water recovery and preparation of ammonia water in the production process of polyetheramine, can solve the problems of large steam consumption and power consumption, difficult process control, low ammonia absorption rate, etc., to achieve Shorten the absorption time, speed up the ammonia absorption process, and increase the effect of ammonia water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

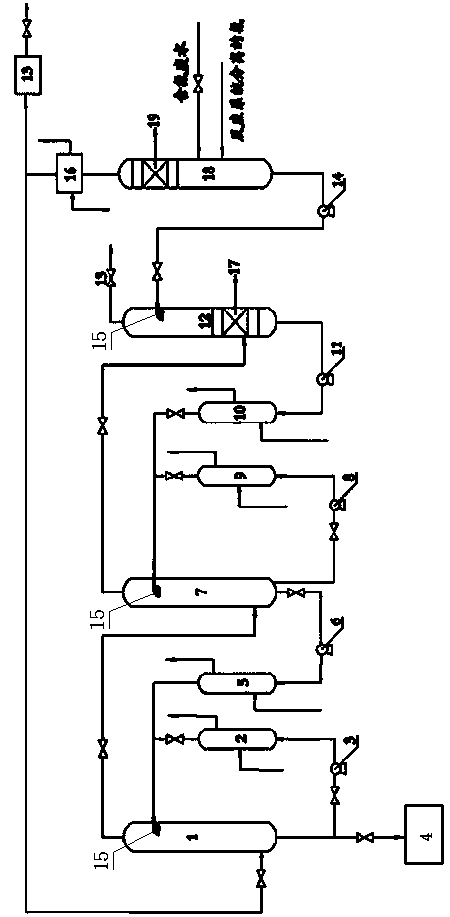

[0020] Ammonia and the by-products containing ammonia from the separation device of the continuous fixed bed production of polyetheramine—ammonia-containing waste water enter the ammonia distillation tower 18 together (there is a built-in condenser 19 in the upper part of the ammonia distillation tower 18) at 0.3MPa and 150 Rectification under the condition of ℃, the gas phase ammonia obtained by rectification is cooled by the subcooler 16 cooled by low-temperature water, and more than 95% of the gas phase ammonia is compressed into liquid ammonia by the ammonia compressor 13 and reused in the fixed bed reactor. % of gaseous ammonia enters the strong ammonia water absorption tower 1 from the bottom of the strong ammonia water absorption tower 1 by residual pressure. The ammonia-containing waste water in the lower part of the ammonia distillation tower 18 is transported by the pump 14 and sprayed from the upper part of the water washing tower 12 into the water washing tower 12 (...

Embodiment 2

[0025] Ammonia and ammonia-containing by-products from the separation device of continuous fixed-bed production of polyetheramine—ammonia-containing waste water enter the ammonia distillation tower 18 (a built-in condenser 19 is built in the upper part of the ammonia distillation tower 18) at 0.1MPa and 200°C Rectification under conditions, the gaseous ammonia obtained by rectification is cooled by the subcooler 16 cooled by low-temperature water, and more than 96% of the gaseous ammonia is compressed into liquid ammonia by the ammonia compressor 13 and reused in the fixed bed reactor, less than 4%. The gaseous phase ammonia enters the strong ammonia water absorption tower 1 from the bottom of the strong ammonia water absorption tower 1 by excess pressure. The ammonia-containing waste water in the lower part of the ammonia distillation tower 18 is transported by the pump 14 from the upper part of the water washing tower 12 into the water washing tower 12 (the lower part of the ...

Embodiment 3

[0030] Ammonia and ammonia-containing by-products from the separation device for continuous fixed-bed production of polyetheramine—ammonia-containing waste water enter the ammonia distillation tower 18 (with a built-in condenser 19 in the upper part) for rectification at 0.2MPa and 180°C. The gas-phase ammonia obtained by distillation is cooled by the subcooler 16 cooled by low-temperature water, and more than 97% of the gas-phase ammonia is compressed into liquid ammonia by the ammonia compressor 13 and reused in the fixed-bed reactor. Enter the strong ammonia water absorption tower 1 from the bottom of the strong ammonia water absorption tower 1. The ammonia-containing waste water in the lower part of the ammonia distillation tower 18 is transported by the pump 14, and sprayed from the upper part of the water washing tower 12 into the water washing tower 12 (the lower part of the water washing tower 12 has an internal condenser 17).

[0031] The unabsorbed part of ammonia is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com