Method for pretreating waste incineration fly ash before melting

A waste incineration fly ash and pretreatment technology, which is applied in the direction of stamping machines, presses, manufacturing tools, etc., can solve the problems of incinerator lining corrosion, system inoperability, and salt content increase, so as to achieve high operating efficiency and solve unnecessary problems. Harmful treatment problems, the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

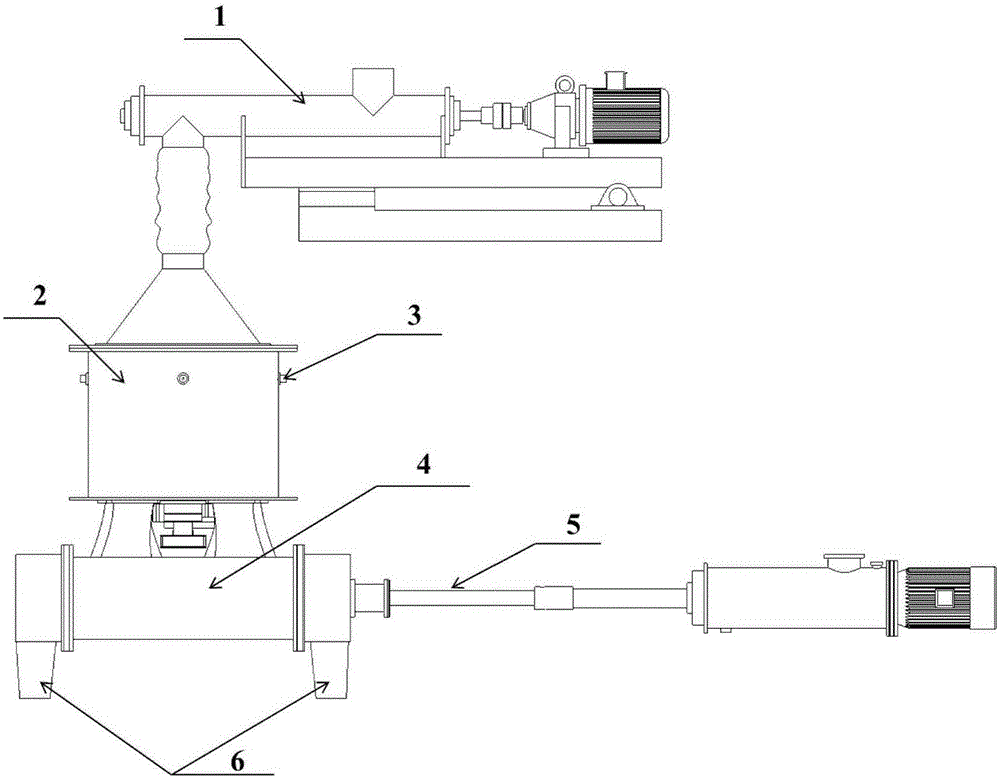

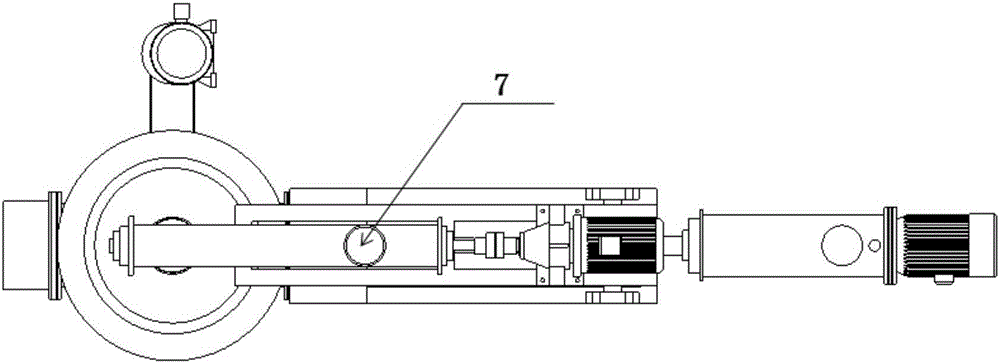

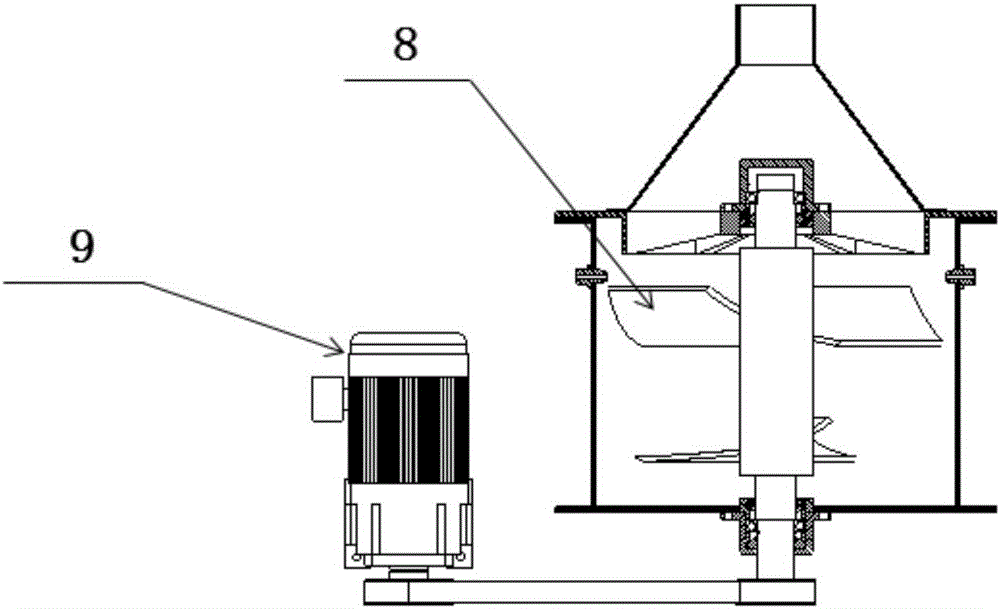

[0016] see Figure 1 ~ Figure 3 , a method for pretreatment of waste incineration fly ash before melting, adopting the following steps: 1) using a mixing mixer 2 to mix and stir the fly ash and the membrane filtration concentrate of landfill leachate to form a muddy mixture; 2) using extrusion molding Machine 4 extrudes the muddy mixture obtained in step 1) into a strip-shaped electric arc furnace raw material.

[0017] In this embodiment, the fly ash is sent into the mixer 2 by a screw feeder 1, and the membrane filtration concentrate of the landfill leachate is sprayed into the mixer 2 by a nozzle 3, and the nozzle 3 is fixed. on the mixing mixer 2. The mixing mixer 2 is provided with a vertical tank body, and a plurality of concentrated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com