Double box opening model of auxiliary valve body of ball valve and casting process

A technology for auxiliary valve bodies and ball valves, which is applied in the field of ball valve auxiliary valve body casting molds. It can solve the problems of large amount of casting repairs, additional investment, disadvantages, etc., and achieves reduced cleaning and processing, high production flexibility, and resource utilization. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

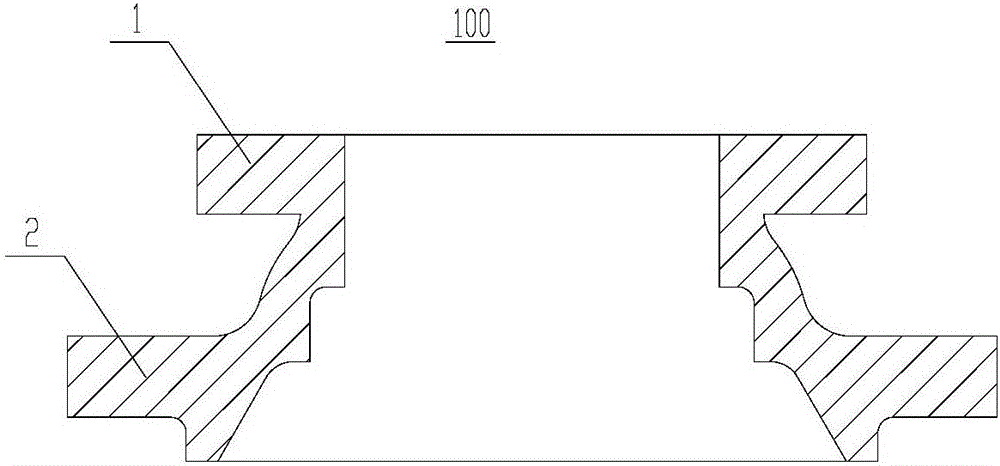

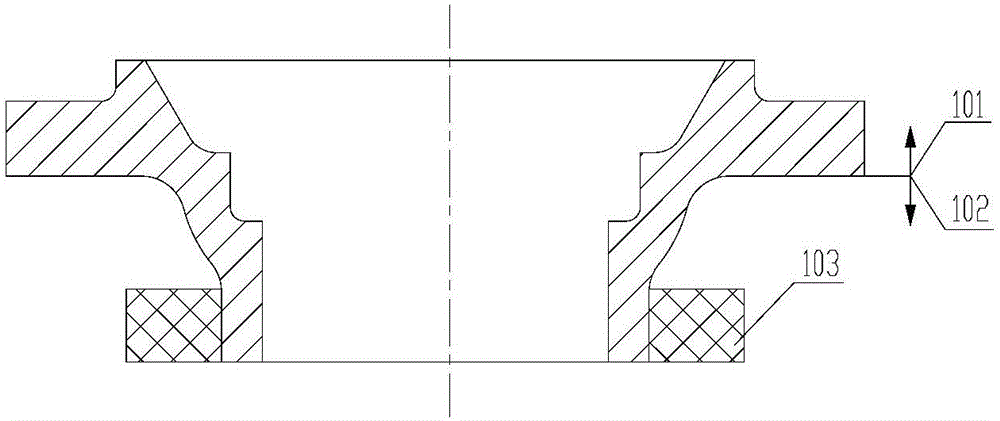

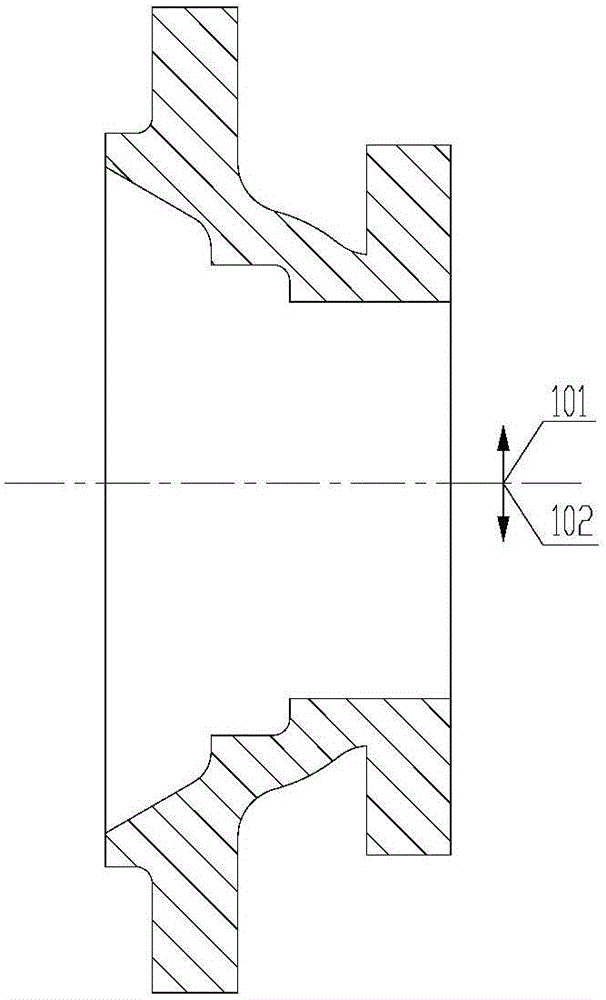

[0028] like Figure 5-9 As shown, a two-open box model of a ball valve auxiliary valve body of the present invention includes an upper box 3, a lower box 4 and a top core 5, and the upper box 3 and the lower box 4 are formed from the side flange 2 of the auxiliary valve body 100. The inner part of the case, the upper case 3 and the top core 5 are parted from the inner side of the end flange 1, the top core 5 is located in the upper case 3, and the top core 5 can rotate 360° along the axial direction , the top core 5 is a truncated cone with a large upper part and a smaller lower part, which is convenient for the top core 5 to be taken out from the upper case 3, and the lower ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com