Special fixture for machining the round cap of special-shaped integrated parts

A special fixture and round cap technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high fixture cost, unstable workpiece size, mass production and high production cost, and reduce production low cost, easy follow-up maintenance, dimensionally stable and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

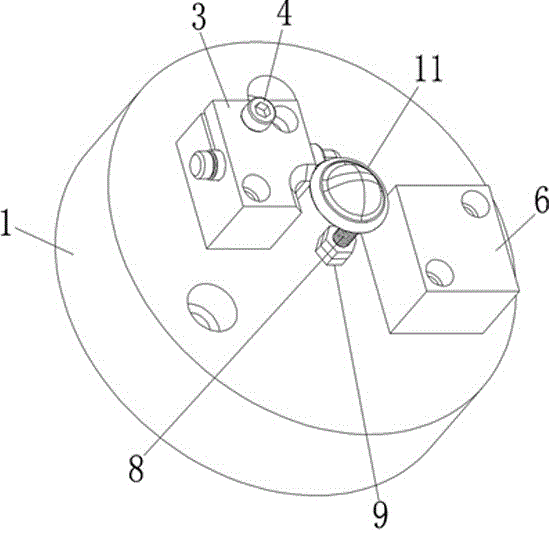

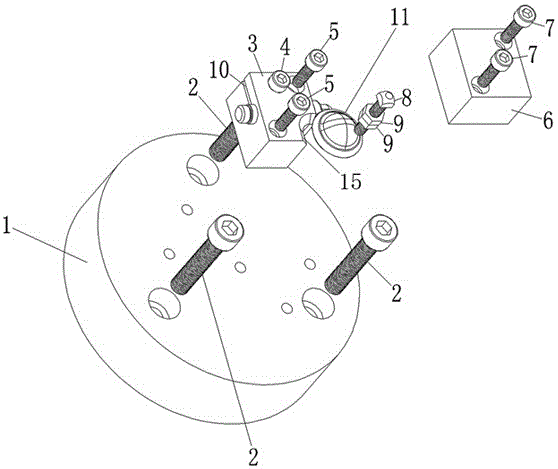

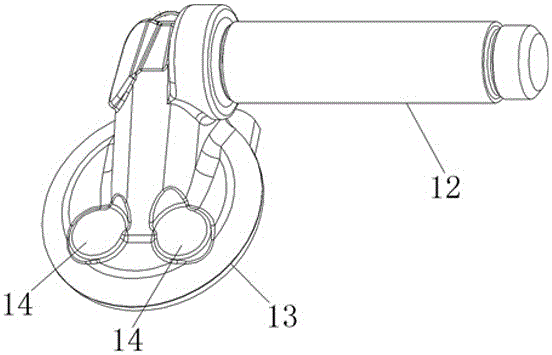

[0019] Such as figure 1 , figure 2 As shown, a special-purpose fixture for machining the round cap of a special-shaped integrated part, including a flat cylindrical fixture body 1 and a positioning block 3, a balance bolt 8 and a balance weight 6 arranged on the upper surface of the fixture body 1, positioning The block 3 and the balance block 6 are respectively arranged on the left and right sides of the balance bolt 8, and the positioning block 3 and the balance block 6 form a place for placing the round cap of the workpiece. The balance bolt 8 corresponds to a boss of the round cap of the workpiece and is set on the fixture In the middle of the upper surface of the main body 1, the positioning block 3 includes a block body, a workpiece shaft positioning hole passing through the block body left and right, and a gap 10 passing through the workpiece shaft position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com