Online heating distortion correcting device, system and method for profile

A torsion straightening and profile technology is applied in the field of on-line heating torsion straightening devices for metal profiles, which can solve the problems of low production efficiency and high labor intensity, and achieve the effects of improving the qualification rate, high degree of automation, and improving straightening efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the drawings and specific embodiments.

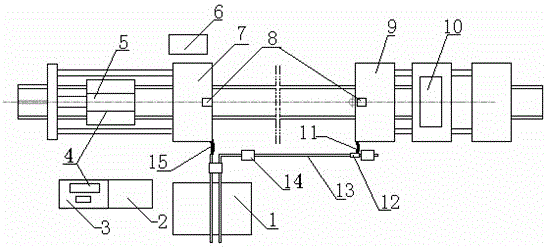

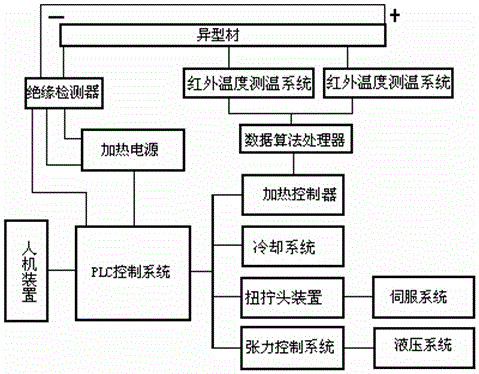

[0035] See figure 1 , An online heating and torsion correction device for profiles, including a straightening cylinder 5, which is connected with the tension control system 4, the hydraulic main pump station 3 and the cooling system 2; the straightening cylinder 5 is provided with a stretching head on one side Device 7, one side of the stretching head device 7 is provided with a twisting head device 9; the twisting head device 9 is connected to the hydraulic auxiliary pump station 10; the stretching head device 7, the twisting head device 9 are both equipped with the same measuring Temperature system 8; the negative water-cooled cable 15 of the stretching head device 7 is connected to the heating power source 1, and the positive water-cooled cable 11 of the twisted head device 9 is connected to the heating power source 1 through a conductive busbar 13.

[0036] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com