Dry/wet composite dedusting system

A compound dust removal, dry and wet technology, applied in the direction of dust removal, combined device, dispersed particle separation, etc., can solve the problems of lowering equipment emission standards, failing to meet the requirements of sustainable development, and dust falling into the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

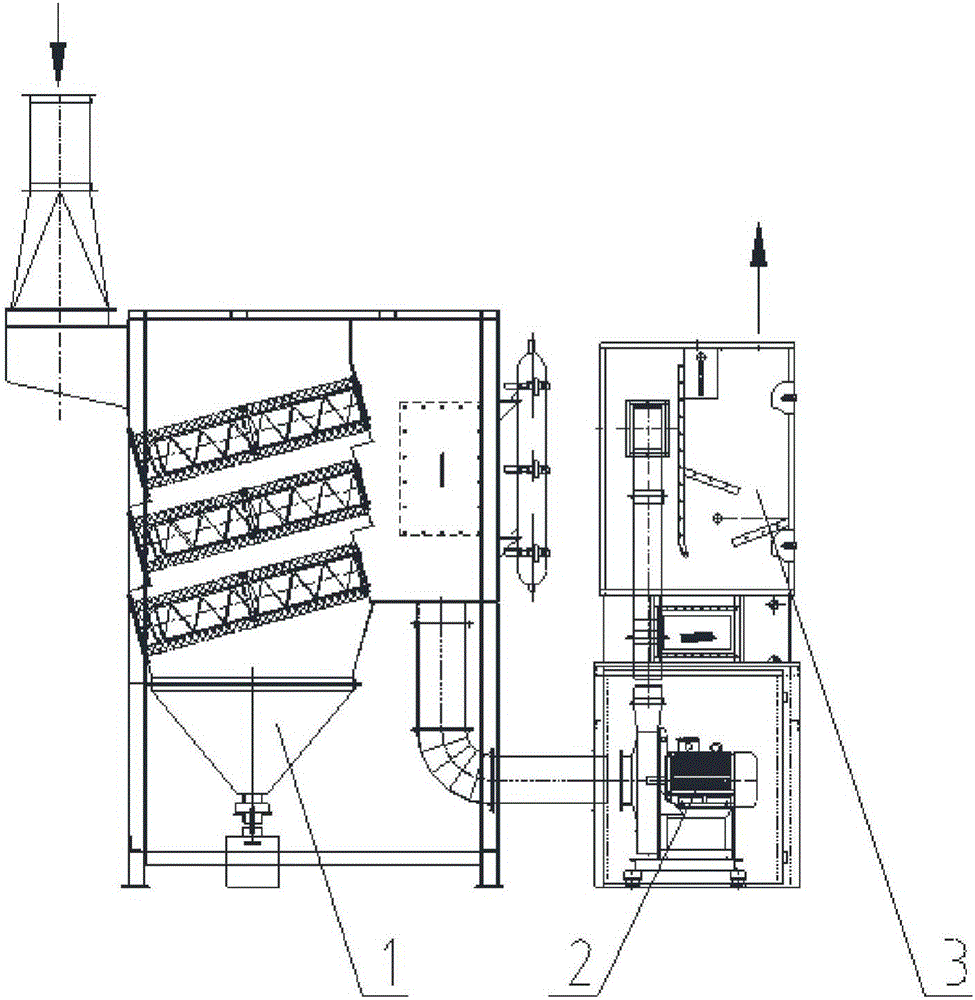

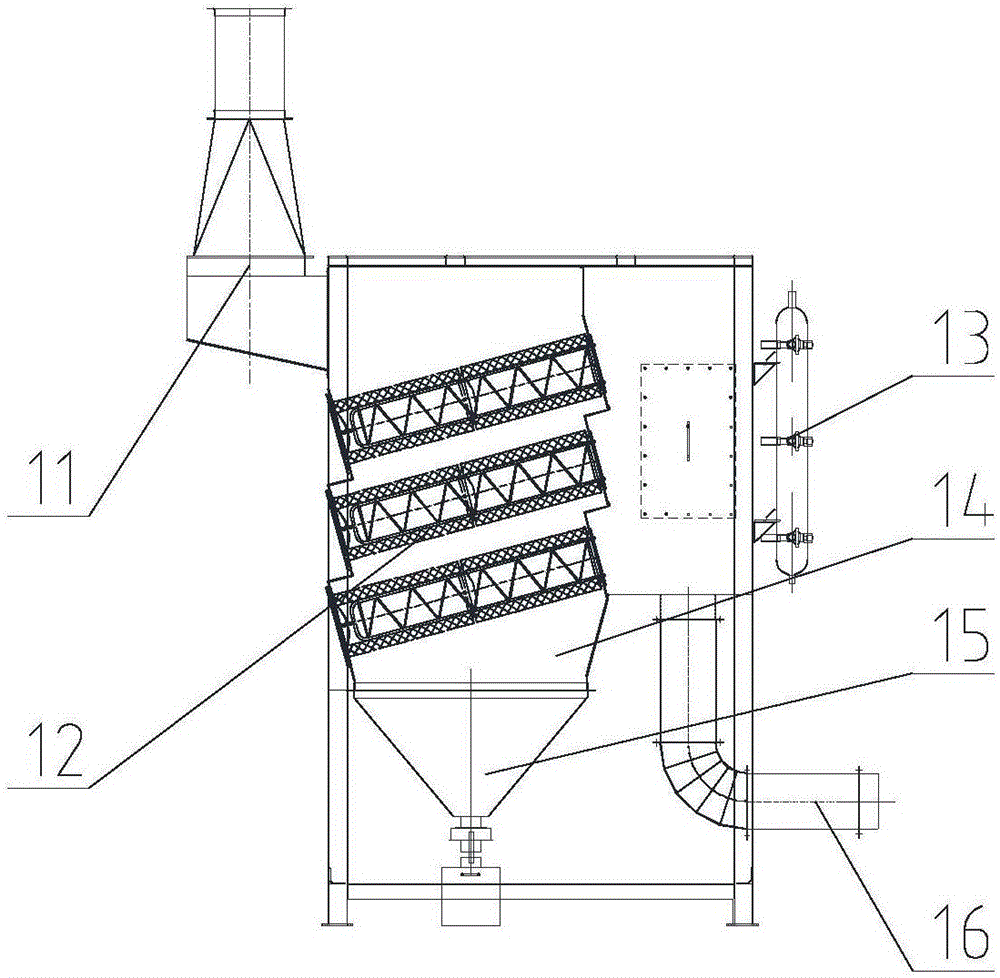

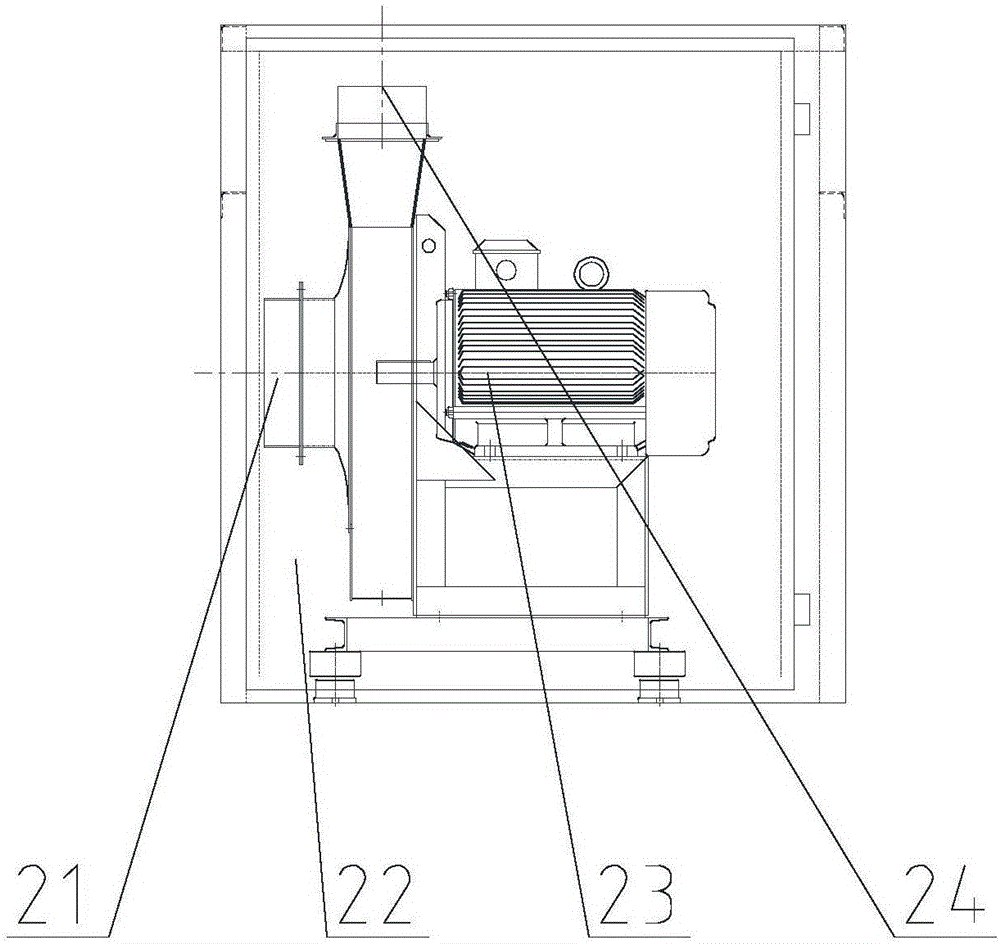

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0026] The present invention provides a dry-wet compound dust removal system, comprising a pulse recoil filter dust collector 1 and a water curtain dust collector 3, the pulse recoil filter dust collector 1 includes a dust removal channel 11 connected to its upper part, and The filter element dust removal mechanism 14 connected to the dust removal passage 11 and the dust removal pipeline outlet 16 connected to one side of the filter element dust removal mechanism 14, the water curtain type dust collector 3 includes a water tank and a filter structure 33 connected sequentially from bottom to top, and the water curtain The system 34 and the water curtain channel outlet 35 arranged on the upper part of the water curtain dust collector 3 , the dust removal pipeline outlet 16 communicates with the water c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com