Design method and device for bone cement spacer female mould

A technology of bone cement and spacer, which is used in medical science, prosthesis, joint implants, etc., can solve the problems of low precision, prolonged hemostasis time, and fast hardening speed of bone cement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

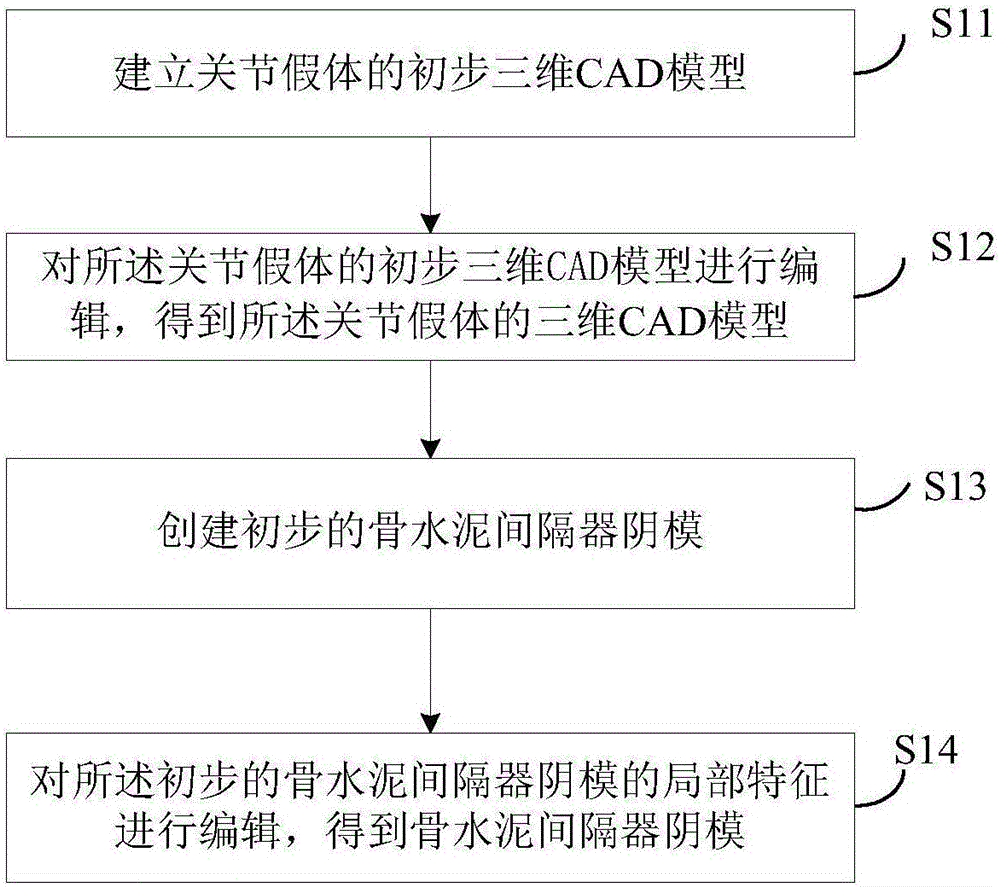

[0065] see figure 1 It is a schematic flow chart of a method for designing a bone cement spacer female mold provided in Embodiment 1 of the present invention. The method includes the following steps:

[0066] S11. Establish a preliminary three-dimensional CAD model of the joint prosthesis according to the collected point cloud data of the patient's joint prosthesis;

[0067] Among them, in the general understanding, the point data geometry of the product appearance surface obtained by measuring instruments in reverse engineering is also called point cloud. Usually, the number of points obtained by using a three-dimensional coordinate measuring machine is relatively small, and the relationship between points and points The spacing is also relatively large, which is called a sparse point cloud; while the number of points in the point cloud obtained by using a 3D laser scanner or a photo scanner is relatively large and dense, it is called a dense point cloud. In an embodiment of...

Embodiment 2

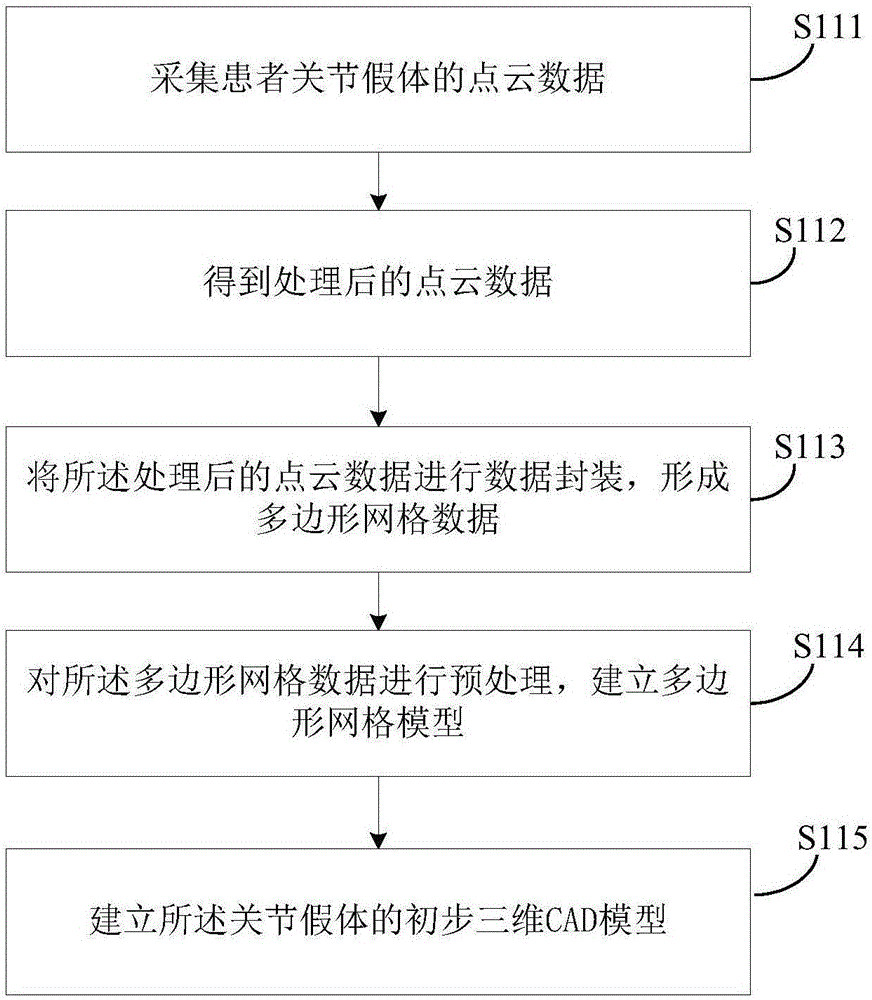

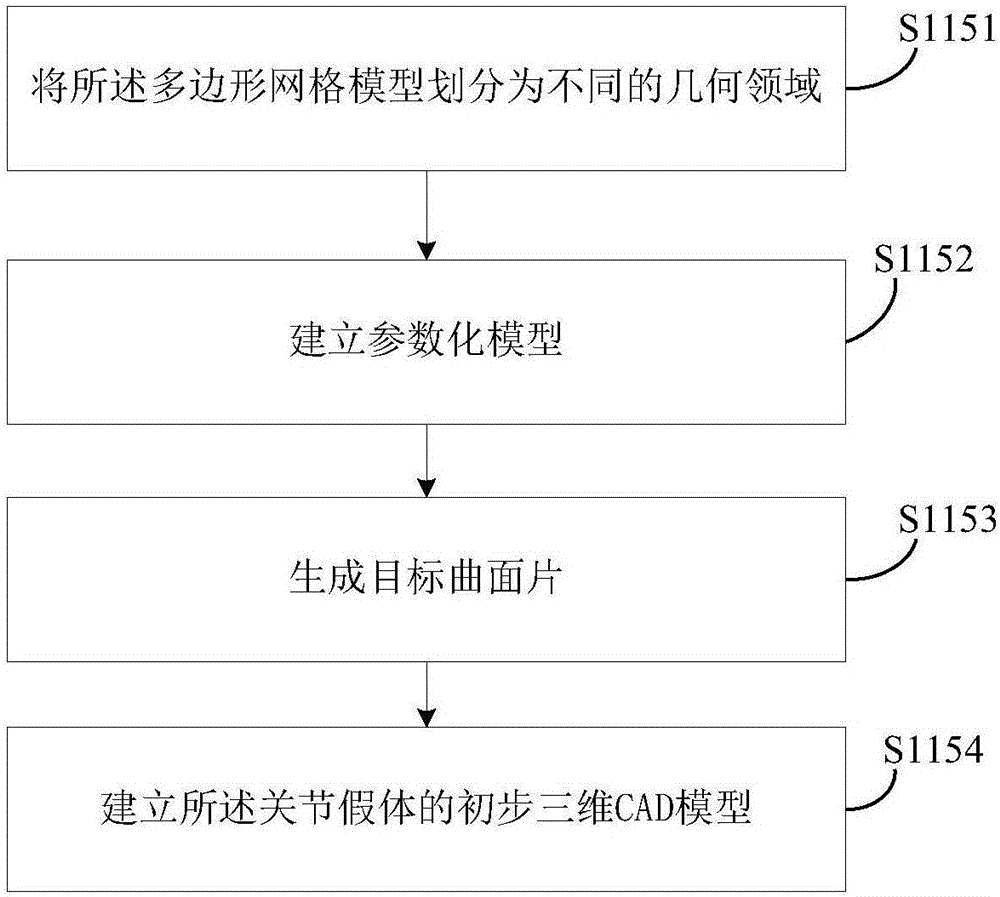

[0076] Referring to embodiment one of the present invention and figure 1 The specific process of steps S11 to S14 described in , and see figure 2 Corresponding to the second embodiment of the present invention figure 1 The schematic flow chart of the preliminary three-dimensional CAD model of establishing joint prosthesis in the shown S11 step, figure 1 Step S11 specifically includes:

[0077] S111, collecting point cloud data of the patient's joint prosthesis;

[0078] S112. Pre-processing redundant point clouds or noise points in the point cloud data to obtain processed point cloud data;

[0079] Specifically, due to the limitation of the scanning technology of the scanner and the influence of the scanning environment, it is inevitable to bring redundant point clouds or prematures. These point clouds can be manually selected to be deleted, and the scanned point cloud data must be aligned and reduced. Noise filtering and streamlining, etc., for subsequent processing.

...

Embodiment 3

[0104] Corresponding to the design method of the female mold of the bone cement spacer disclosed in the first and second embodiments of the present invention, the third embodiment of the present invention also provides a design device for the female mold of the bone cement spacer, see Figure 6 A schematic structural view of the design device for the bone cement spacer female mold provided in Embodiment 3 of the present invention, and Figure 7 It is a schematic structural diagram of the first establishment unit provided in Embodiment 3 of the present invention. The device specifically includes:

[0105] The first building module 31 is used to establish a preliminary three-dimensional CAD model of the joint prosthesis according to the collected point cloud data of the patient's joint prosthesis;

[0106] The first editing module 32 is used to edit the features other than the non-key curved surface of the preliminary three-dimensional CAD model of the joint prosthesis according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com