Dryer suitable for nutrition powder and operation method thereof

A nutritional powder and dryer technology, applied in application, food science, food preservation and other directions, can solve the problems of the destruction of active ingredients of nutritional powder, difficult temperature adjustment, inconvenient operation, etc., to improve quality, improve drying efficiency and drying efficiency. Dry mass, the effect of improving airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

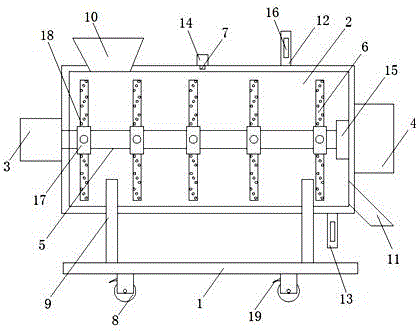

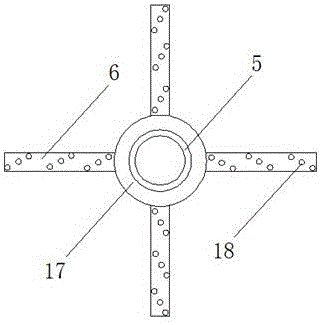

[0023] as attached figure 1 and 2 As shown, a drying machine suitable for nutrition powder includes a base plate 1, a drying chamber 2, a motor 3, a blower 4, a transmission shaft 5, a stirring rod 6 and a walking wheel 8, and it is characterized in that the base plate 1 A bracket 9 is arranged on the top, and the drying chamber 2 is arranged on the bracket 9, and the outer wall of the drying chamber 2 is provided with a feed inlet 10, a discharge outlet 11, a water outlet pipe 12, a water inlet pipe 13, a thermometer 14, and A bearing 15 is arranged on the inner wall of the drying chamber 2, and an interlayer is arranged on the drying chamber 2, and the interlayer is connected with the water inlet pipe 13 and the water outlet pipe 13, and a temperature sensor 7 is arranged in the described interlayer, and The temperature sensor 7 is connected with the thermometer 14, the water inlet pipe 13 and the water outlet pipe 12 are provided with valves 16, the motor 3 and the blower ...

Embodiment 2

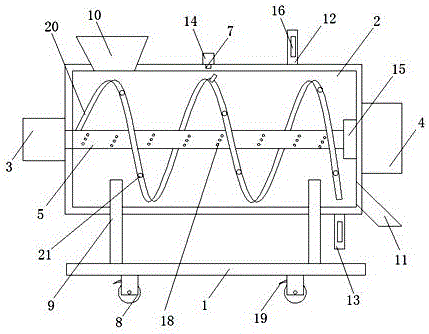

[0030] 1. Bottom plate, 2. Drying chamber, 3. Motor, 4. Blower, 5. Transmission shaft, 6. Stirring rod, 7. Temperature sensor, 8. Traveling wheel, 9. Bracket, 10. Feed inlet, 11 .Outlet, 12. Outlet pipe, 13. Inlet pipe, 14. Thermometer, 15. Bearing, 16. Valve, 17. Connection block, 18. Air outlet, 19. Lock, 20. Stirring plate, 21. Hair brush.

[0031] as attached image 3 As shown, a drying machine suitable for nutrition powder includes a base plate 1, a drying chamber 2, a motor 3, a blower 4, a transmission shaft 5, a walking wheel 7 and a stirring plate 20, and it is characterized in that the base plate 1 A bracket 9 is arranged on the top, and the drying chamber 2 is arranged on the bracket 9, and the outer wall of the drying chamber 2 is provided with a feed inlet 10, a discharge outlet 11, a water outlet pipe 12, a water inlet pipe 13, a thermometer 14, and A bearing 15 is arranged on the inner wall of the drying chamber 2, and an interlayer is arranged on the drying c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com