A thick film circuit rare earth electrode slurry based on stainless steel substrate and preparation method thereof

A technology of rare earth electrode paste and thick film circuit, which is applied to the manufacture of conductive materials, circuits, cables/conductors dispersed in non-conductive inorganic materials, etc. It can solve the problems of high cost, unfavorable environmental protection, etc., and achieve low equipment requirements , good weldability and improved adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A thick-film circuit rare-earth electrode slurry based on a stainless steel substrate, in terms of mass percentage, consists of the following components:

[0043] Composite functional phase 65%,

[0044] Inorganic binder phase 5%,

[0045] organic vehicle 30%,

[0046] The stainless steel substrate is a stainless steel plate;

[0047] The composite functional phase is composed of the following components in terms of mass percentage:

[0048] Nano spherical silver powder 90%,

[0049] Palladium powder 5%,

[0050] CeO 2 5%;

[0051] The inorganic bonding phase is lead-free glass-ceramic powder, and is composed of the following components in terms of mass percentage:

[0052] SiO 2 25%, CaO 20%,

[0053] B 2 o 3 30%, Al 2 o 3 10%,

[0054] Bi 2 o 3 10%, TiO 2 5.0%;

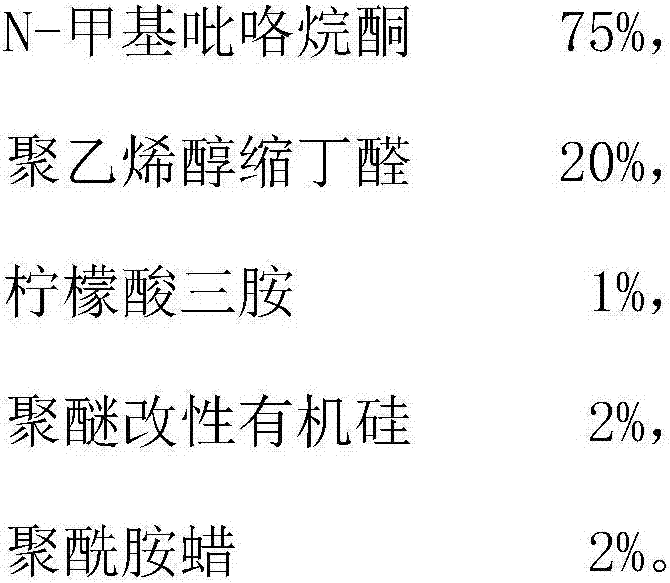

[0055] Described organic carrier, by mass percentage, comprises following components:

[0056]

[0057] Its preparation method comprises the following steps:

[0058] (1) Preparatio...

Embodiment 2

[0067] A thick-film circuit rare-earth electrode slurry based on a stainless steel substrate, in terms of mass percentage, consists of the following components:

[0068] Composite functional phase 70%,

[0069] Inorganic binder phase 5%,

[0070] Organic vehicle 25%;

[0071] The stainless steel substrate is a stainless steel pipe;

[0072] The composite functional phase is composed of the following components in terms of mass percentage:

[0073] Nano spherical silver powder 85%,

[0074] Palladium Powder 10%,

[0075] SM 2 o 3 5%;

[0076] The inorganic bonding phase is lead-free glass-ceramic powder, and is composed of the following components in terms of mass percentage:

[0077] SiO 2 40%, CaO 15%,

[0078] B 2 o 3 25%, Al 2 o 3 7.5%,

[0079] Bi 2 o 3 7.5%, ZrO 2 5.0%;

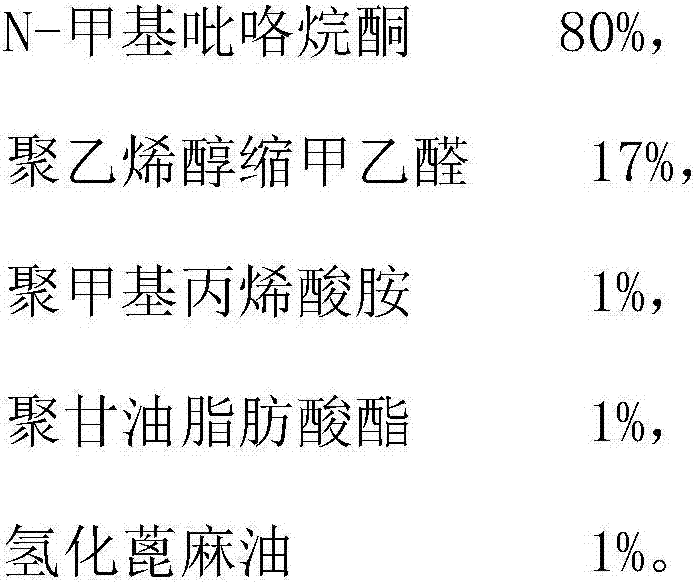

[0080] Described organic carrier, by mass percentage, comprises following components:

[0081]

[0082] Its preparation method comprises the following steps:

[0083] (1) Pr...

Embodiment 3

[0092] A thick-film circuit rare-earth electrode slurry based on a stainless steel substrate, in terms of mass percentage, consists of the following components:

[0093] Composite functional phase 79%,

[0094] Inorganic binder phase 1%,

[0095] organic vehicle 20%,

[0096] The base material is a stainless steel plate;

[0097] The composite functional phase is composed of the following components in terms of mass percentage:

[0098] Nano spherical silver powder 80%,

[0099] Palladium Powder 10%,

[0100] Gd 2 o 3 10%;

[0101] The inorganic bonding phase is lead-free glass-ceramic powder, and is composed of the following components in terms of mass percentage:

[0102] SiO 2 35%, CaO 20%,

[0103] B 2 o 3 25%, Al 2 o 3 7.5%,

[0104] Bi 2 o 3 7.5%, MoO 3 5%;

[0105] Described organic carrier, by mass percentage, comprises following components:

[0106]

[0107] Its preparation method comprises the following steps:

[0108] (1) Preparation of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com