Method for representing inclusions of different sizes, in tire cord steel, in ternary phase diagrams

A ternary phase diagram and inclusion technology, which is applied in 2D image generation, image data processing, 3D modeling, etc., can solve the problem that the cloud image coverage cannot be correctly represented, the reading of the quantity is affected, the inclusion size is not accurate, Intuitive expression and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) In this example, SC82AM steel was used to prepare metallographic samples, and the inlaid metallographic samples were standardized using an automatic grinding machine;

[0026] (2) Put the sample processed in step (1) into the scanning electron microscope, and carry out statistics on the surface distribution of inclusions in combination with automatic inclusion analysis software. The Minimum Size is set to 1 μm, and the Maximum Size is set to 225 μm;

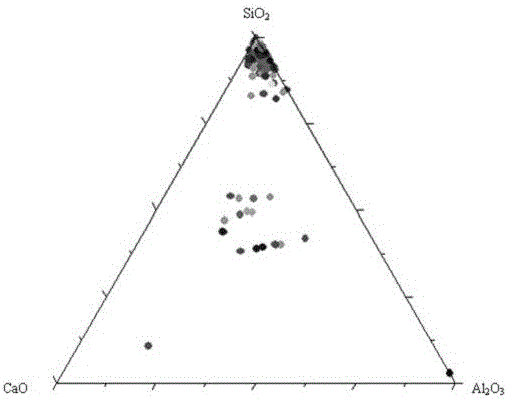

[0027] (3) Screen the data obtained from statistics on the surface distribution of inclusions, according to CaO-Al 2 o 3 - SiO 2 Ca-Si-Al type inclusions are screened out from the series inclusions, and converted into CaO and SiO according to the normalized treatment of weight percentage 2 、Al 2 o 3 ;

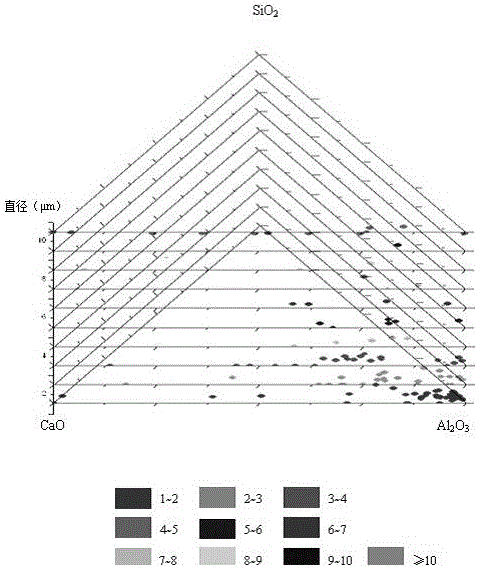

[0028] (4) Filter data with 1 μm as the length interval, specifically: 1 μm ≤ D < 2 μm, 2 μm ≤ D < 3 μm, 3 μm ≤ D < 4 μm, 4 μm ≤ D < 5 μm, 5 μm ≤ D < 6 μm, 6 μm ≤ D < 7μm, 7μm≤D<8μm, 8μm≤D<9μm, 9μm≤D<10μm, D≥10μm;...

Embodiment 2

[0031] This embodiment uses SWRS87Mn steel to prepare metallographic samples, and the steps and operation methods adopted are the same as those of the above-mentioned embodiment 1, such as image 3 As shown, grayscale processing is done in this document.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com