Digital bidirectional constant current source

A constant current source, digital technology, applied in the direction of adjusting electrical variables, control/regulating systems, instruments, etc., can solve problems such as system scalability and flexibility limitations, stand-alone operation, and inability to use microcomputer program control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 Overall structure of the system

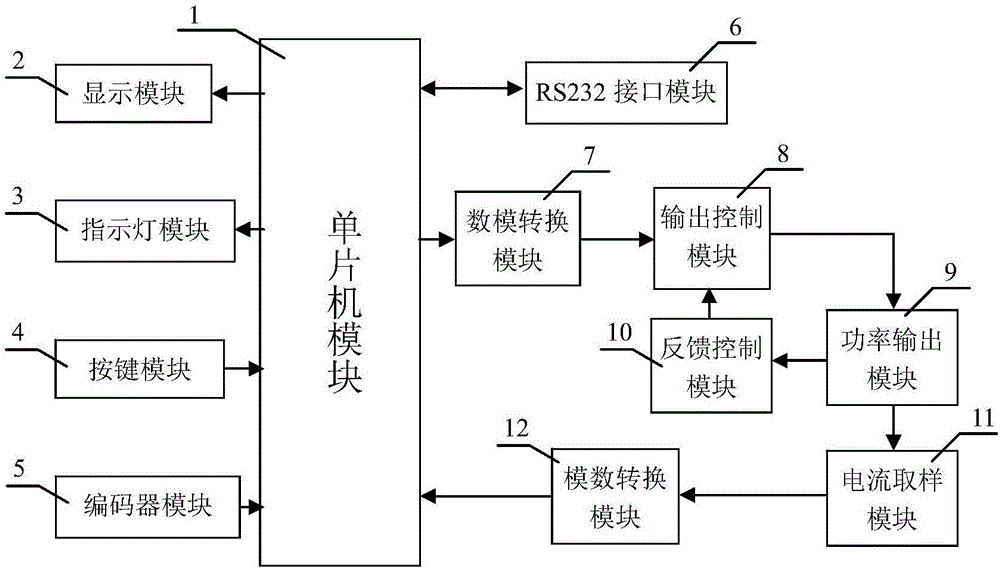

[0042] Such as figure 1 and Figure 14 As shown, the system structure includes MCU module 1, display module 2, indicator light module 3, button module 4, encoder module 5, RS232 interface module 6, digital-to-analog conversion module 7, output control module 8, power output module 9, feedback A control module 10 , a current sampling module 11 , an analog-to-digital conversion module 12 and a front panel 13 .

Embodiment 2

[0043] Embodiment 2 MCU module

[0044] Such as figure 2 As shown, the structure of the single-chip microcomputer module 1 is that the power supply terminal and the ground terminal of the single-chip microcomputer U1 are connected to +5V power supply and digital ground respectively, the power supply terminal is also connected to the digital ground through the capacitor C1, and the crystal oscillator Y1 is connected between the port X1 and the port X2. Port X1 and port X2 are also connected to digital ground through capacitor C2 and capacitor C3 respectively, and ports P00 to port P07 are respectively connected to +5V power supply through resistors R1 to R8. ), P1 mouth (P10~P17), P2 mouth (P20~P27) are common input / output ports, use P0 mouth in the present invention as the data exchange mouth of single-chip microcomputer and A / D, D / A and display chip, P2 Each pin of the port and P3 port is used as the control terminal to realize the coordinated work of the chips in the contr...

Embodiment 3

[0045] Embodiment 3 display module

[0046] Such as image 3 As shown, the structure of the display module 2 is that the ports D0-D7 of the display screen U2 are respectively connected to the ports P00-P07 of the single-chip microcomputer U1, and the ports EN, port R / W and port RS of the display screen U2 are connected to the single-chip microcomputer respectively. Port P10, port WR and port RD of U1, port VL and port BL- of display screen U2 are connected to digital ground, port BL+ is connected to the sliding wire end of sliding rheostat W1, port VDD and port VSS are respectively connected to +5V power supply and digital ground, A capacitor C4 is also connected between the port VDD and the port VSS, one end of the sliding rheostat W1 is connected to a +5V power supply, and the other end is connected to a digital ground. The model of the display screen U2 is LCD1602, which is a 16*2 integrated liquid crystal display with 14 pins in total. The port VDD and the port VSS are th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com