Side detection system and method for glass substrate

A glass substrate and detection system technology, applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problems that the beat of the production line is greatly affected and the operating efficiency of the production line is affected, and achieve the effects of reducing errors, increasing service life, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, the glass substrate to be tested is one piece.

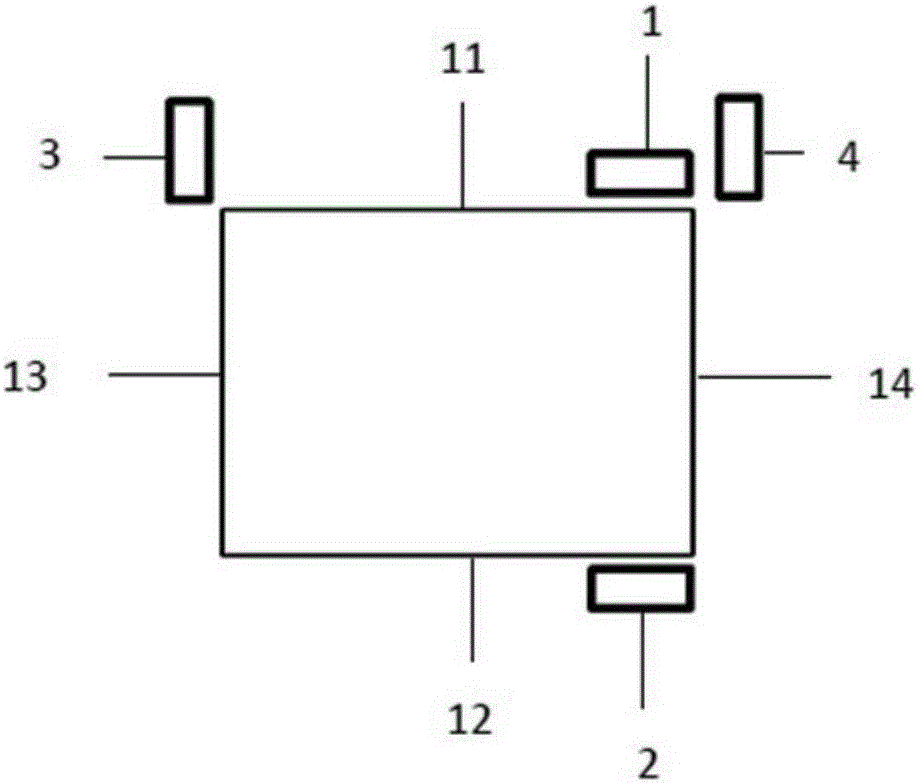

[0038] In this embodiment, the glass substrate to be tested is a neutral borosilicate glass substrate, and the shape of the glass substrate to be tested is a square with a side length of 1300 mm×1300 mm. The first side 11, the second side 12, the third side 13, and the fourth side 14 of the glass substrate to be tested are as figure 1 As shown, this embodiment is provided with four glass substrate edge detectors.

[0039] The first detector 1 and the second detector 2 are symmetrically fixed on both sides of the glass substrate, respectively located at the end points of the same side of the first side 11 and the second side 12 of the glass substrate to be tested, and the glass substrate to be tested With the movement of the conveyor belt, under the condition that the glass substrate is moving and the first detector 1 and the second detector 2 are stationary, when the neutral borosilicate glass substra...

Embodiment 2

[0045] In this embodiment, there are three glass substrates to be tested. The glass substrate edge detection system of this embodiment can intermittently detect two glass substrates at the same time.

[0046] The liquid crystal glass substrate described in this embodiment is soda glass, rectangular in shape, the length of the first side and the second side is 1850mm, and the length of the third side and the fourth side is 1500mm. The edge inspection system for glass substrates detects two glass substrates at the same time, such as figure 2 shown.

[0047] The glass substrate 5, the glass substrate 6 and the glass substrate 7 move along the preset direction with the conveyor belt, the first detector 1 and the second detector 2 are fixedly arranged, and the third detector 3 and the fourth detector 4 are located in two adjacent blocks to be Measure between the glass and move under the drive of the driver.

[0048] When the first side and the second side of the glass substrate...

Embodiment 3

[0056] In this embodiment, there are three glass substrates to be tested. The glass substrate edge detection system of this embodiment can continuously detect two glass substrates at the same time.

[0057] The liquid crystal glass substrate described in this embodiment is soda glass, rectangular in shape, the length of the first side and the second side is 1850mm, and the length of the third side and the fourth side is 1500mm. The edge inspection system for glass substrates detects two glass substrates at the same time, such as image 3 shown.

[0058] In this embodiment, the third detector 3 and the fourth detector 4 move synchronously, and the moving speed is V 2 , V 2 V in Example 2 0 and V 1 The sum, that is, the third detector 3 and the fourth detector 4 move synchronously with the glass substrate while moving along the third side and the fourth side, so that it is completed under the condition of continuous movement of the conveyor belt. Inspection of the edge of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com