an in situ soil feeding 13 co 2 systems and methods

A soil, in-situ technology, used in soil material testing, material inspection products, etc., to achieve the effect of reducing external interference and simple operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

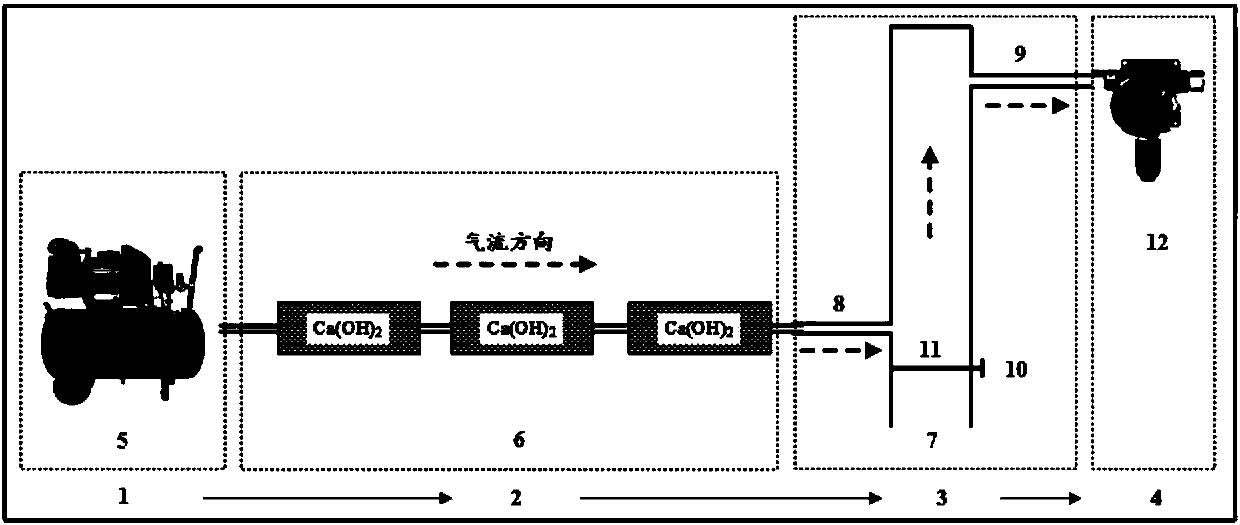

[0037] to combine figure 1 shown, one for feeding the soil 13 CO 2 system, including power unit 1, filter unit 2, feeding unit 3 and CO 2 detection device 4; wherein,

[0038] Described power unit is commercially available air pump 5;

[0039] The filtering device includes a drying pipe 6 and rubber conduits connected to the drying pipes; the drying pipes 6 are respectively connected through rubber conduits. In the drying tube 6 is solid Ca(OH) 2 ;

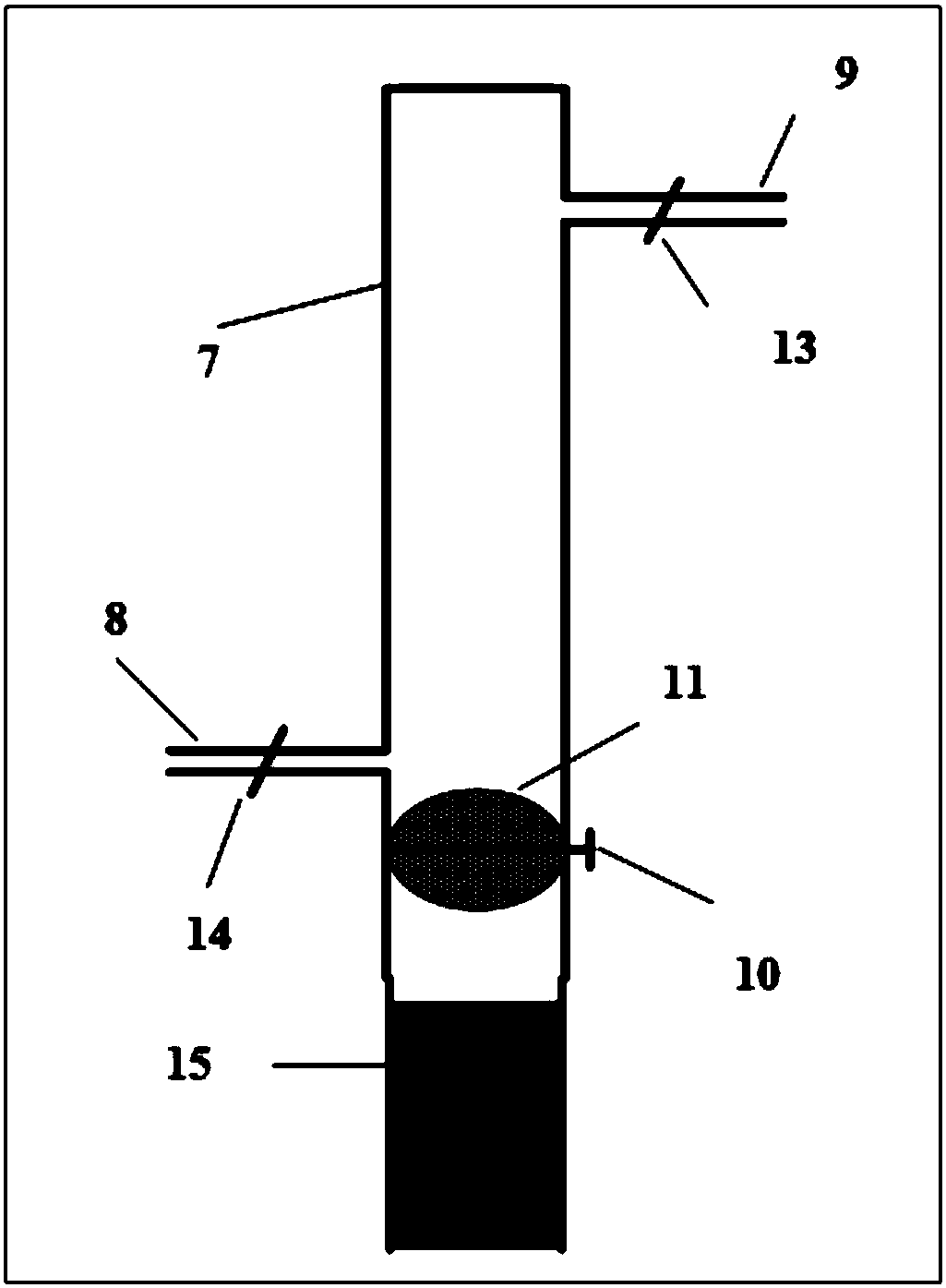

[0040] The feeding device comprises a plexiglass cylinder 7, an air injection pipe 8, an exhaust pipe 9, an exhaust pipe switch valve 13, an air injection pipe switch valve 14, a circular baffle 11, and a knob 10 for controlling the baffle switch;

[0041] The CO 2 The detection device is commercially available CO 2 analyzer12.

[0042] The air pump 5 provides power for gas flow for the whole system; the air pump 5 is connected with the filter device 2 .

[0043]In the filter device 2 of the present invention, the outsid...

Embodiment 2

[0049] Embodiment 2 feeding method

[0050] Feeding the soil using the system described in Example 1 13 CO 2 system feeding soil 13 CO 2 method, including the following steps:

[0051] 1) the soil ring 15 is driven into the ground vertically, and then the soil ring 15 is connected with the feeding device 3 ( figure 2 ), repeatedly wrap the joint with waterproof tape to prevent air leakage at the interface between the cylinder and the soil ring;

[0052] 2) The power unit 1, filter unit 2, feeding unit 3 and CO 2 The detection device 4 is connected; rotate the knob 10 on the cylinder to make the circular baffle 11 horizontal, so that the space above the glass cylinder baffle is in a completely sealed state;

[0053] 3) Open the switching valves 13, 14 of the gas injection pipe 14 and the exhaust pipe 13; start the air pump 5, control the air to 10Lmin -1 The flow rate flows out from the air pump 5, through Ca(OH) 2 The air in the drying pipe 6 enters the plexiglass cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com