Method for measuring irregular objects on the bag loading platform of cross-belt sorter

A technology of cross-belt sorting and measurement method, applied in the field of logistics, can solve the problems of alarm blanking, high wrong package rate, easy to be interfered, etc., and achieve the effect of reducing workload, improving applicability, and reducing labor intensity of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

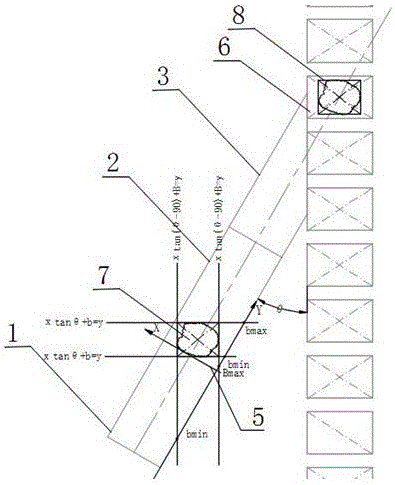

[0013] Further illustrate below in conjunction with the embodiment of accompanying drawing

[0014] Such as figure 1 As shown, the bag-up platform includes a belt conveyor 1 in the bag-up section, a belt conveyor 2 in the synchronous section, and a belt conveyor 3 in the confluence section. The measurement light curtain 5 is installed between the belt conveyor 1 of the upper bag section and the belt conveyor 2 of the synchronous section, the light curtain controller and the programmable control PLC are installed in the control box 4, and the measurement light curtain and the light curtain controller are connected by cables. The programmable control PLC and the light curtain controller are connected through RS485 wiring, and the free port communication protocol is used for communication. It is required to measure the distance between the first optical axis of the light curtain and the edge of the belt to be an optical axis. It is required that when the object passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com