High-brightness LED flexible neon lamp

A high-brightness, neon lamp technology, applied in lighting and heating equipment, point light sources, lighting devices, etc., can solve the problems that the lamp body cannot be bent left and right along the light-emitting surface, low production efficiency, high cost, etc., to reduce total reflection, Improve the brightness of the lamp body and maximize the effect of the brightness of the lamp body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

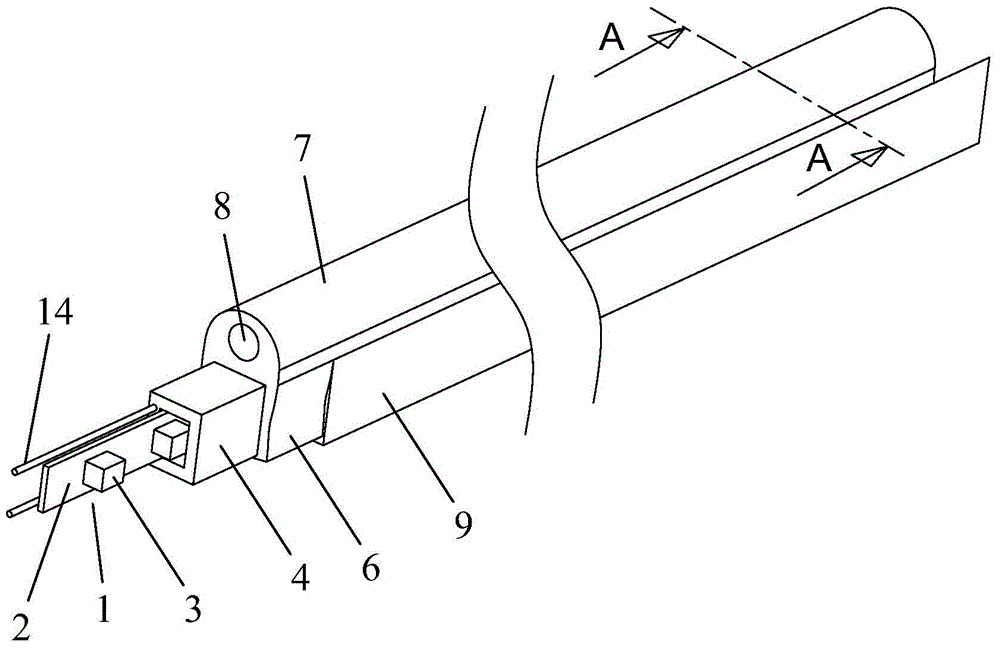

[0041] refer to Figure 1-4 The preferred embodiment one of the present invention shown is a high-brightness LED flexible neon lamp, comprising:

[0042] A strip-shaped flexible light board 1, the light board 1 includes a flexible circuit board 2 and a plurality of patch LEDs 3 arranged on the flexible circuit board 2; the LEDs 3 are white LEDs, of course, RGB LEDs can also be used.

[0043] A strip-shaped transparent first insulating plastic layer 4 has a first through hole 5 along the length direction, and the flexible light board 1 is arranged in the first through hole 5;

[0044] A strip-shaped light-transmitting insulating plastic sheath 6 is coated on the periphery of the first insulating plastic layer 4, and the top of said sheath 6 is provided with a light-emitting body 7, said light-emitting body 7 and sheath 6 being integrally structured, said sheath 6 and Light-emitting body 7 is equipped with astigmatism powder; the cross-section of the light-emitting body 7 is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com