Lens for LED lamp

A technology for LED lamps and lenses, which is applied in the parts of lighting devices, semiconductor devices of light-emitting elements, lighting devices, etc., can solve the problems of uneven light distribution of LED chips and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

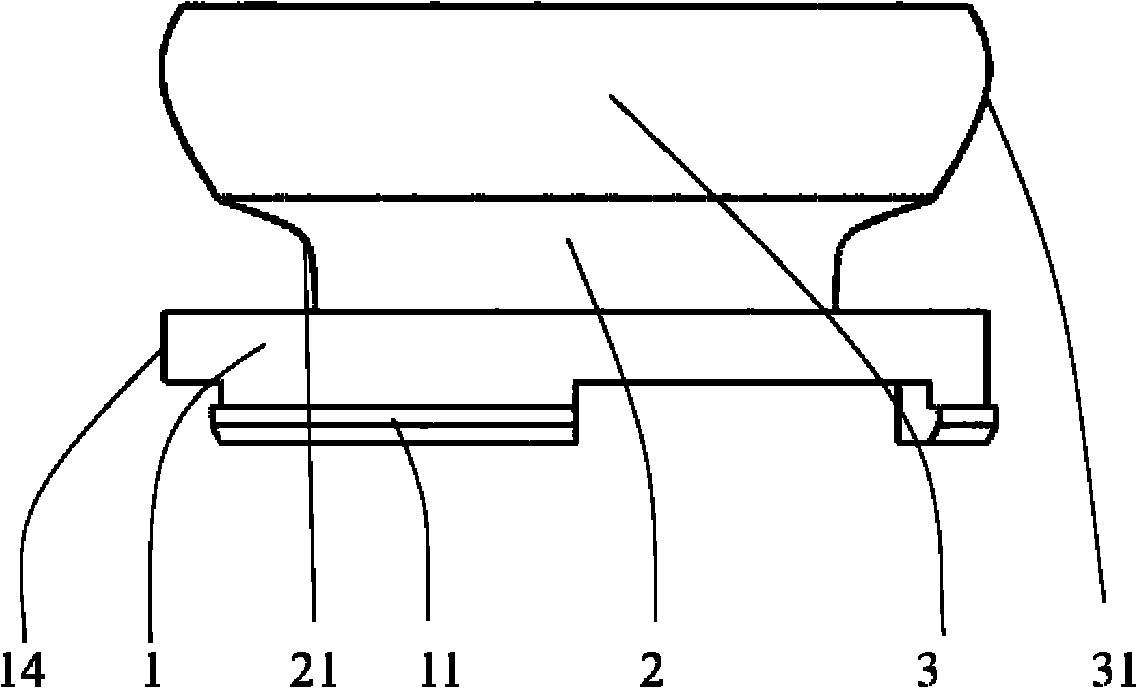

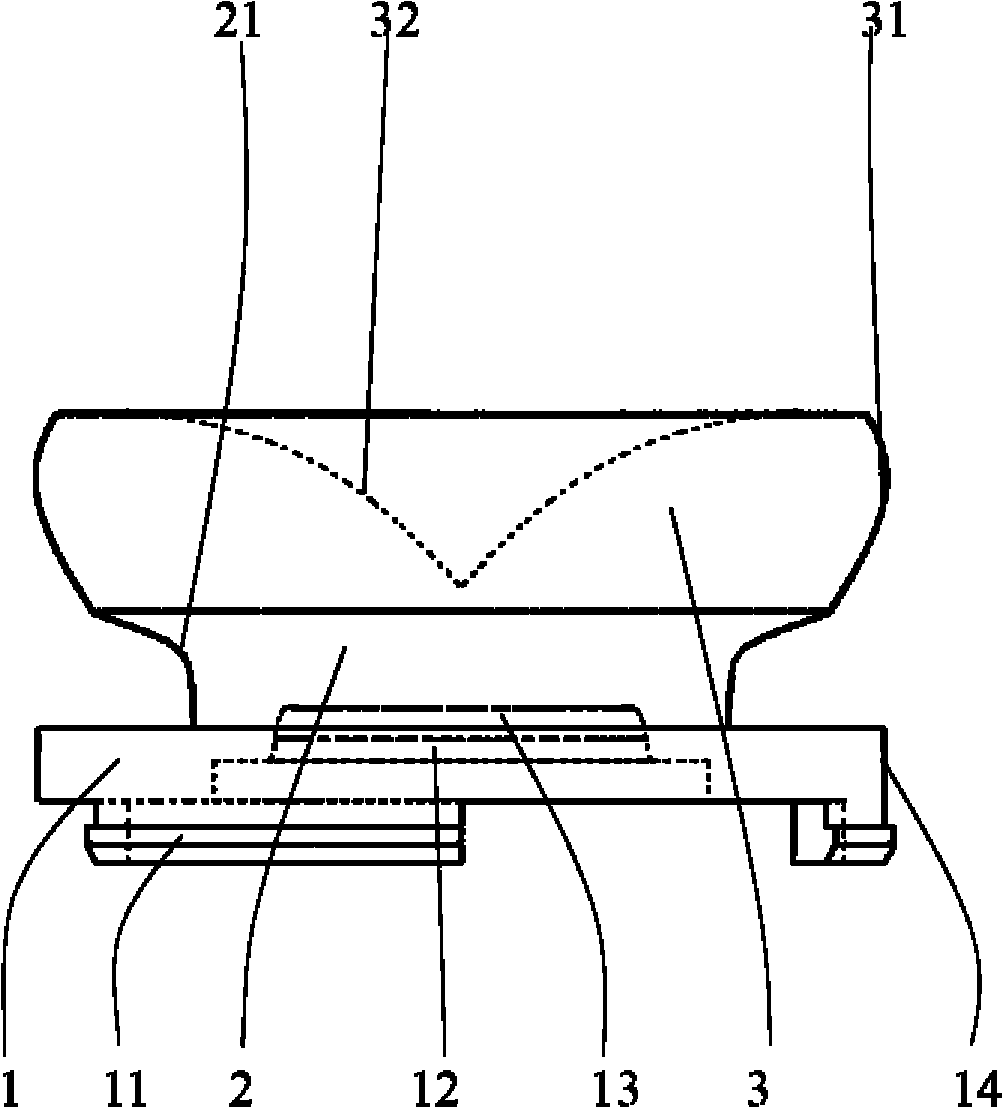

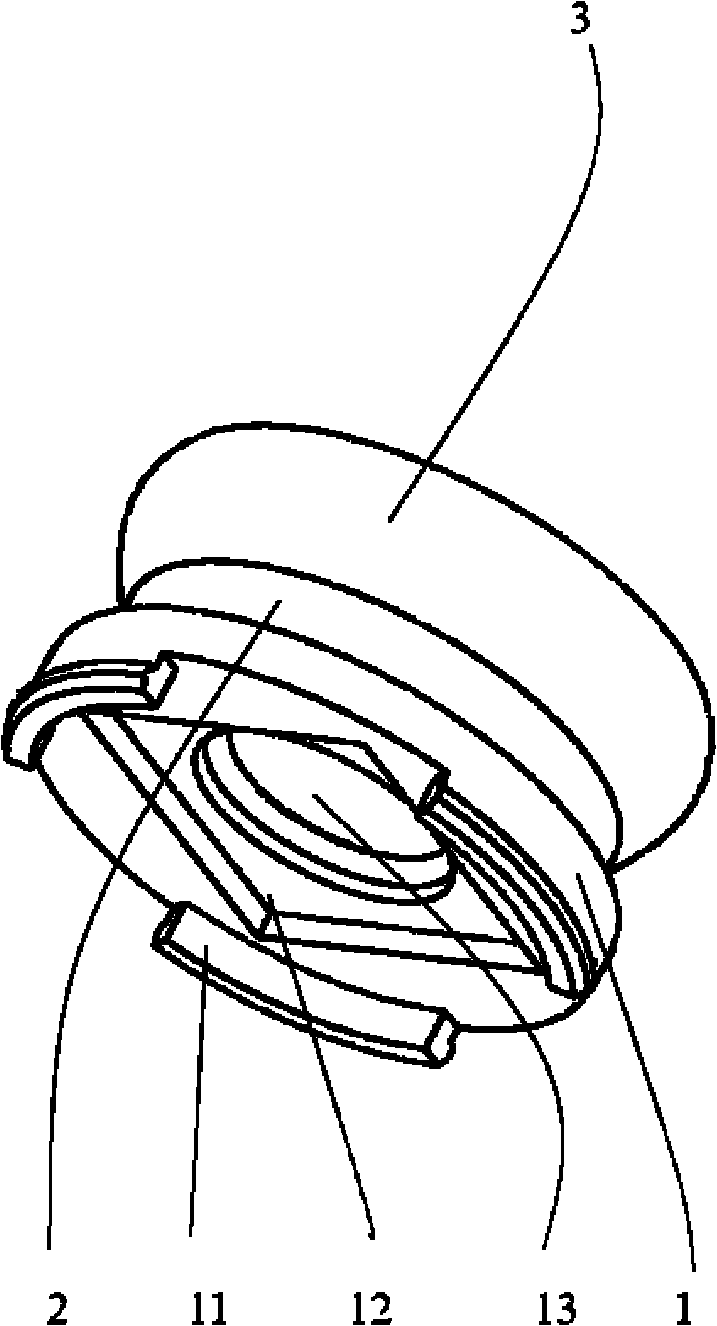

[0023] reference Figure 1 to Figure 3 As shown, a preferred implementation structure for an LED lens provided by the present invention includes a fixed base 1, a first beam splitter 2 and a second beam splitter 3.

[0024] The fixed base 1 is located at the bottom end of the lens. The fixed base 1 includes a cylinder 14 and three buckles 11. The number of buckles can be set according to specific requirements. The structure of the buckles can also be varied. Too much repeat. At the bottom of the fixed base 1, there is a space 12 for placing the LED chip. This space 12 is also determined according to the shape of the specific LED chip. The upper space 13 of the chip is used to initially distribute the light emitted by the LED chip. This space 13 is similar Round truncated space, the height of the space depends on the specific LED chip.

[0025] The first luminous body 2 is located on the fixed base 1, and the diameter of the upper surface of the fixed base 1 is larger than the diam...

Embodiment 2

[0029] Please refer again Figure 4 to Figure 6 Shown is another preferred implementation structure improved by this invention, which also consists of a fixed base 1, a first beam splitter 2 and a second beam splitter 3. The biggest difference from the foregoing structure is that the diameter of the upper surface of the first beam splitter 2 is larger than the diameter of the lower surface of the second beam splitter 3, and the second beam splitter 3 is a truncated cone-shaped structure with a larger lower surface diameter and a smaller upper surface diameter. The first beam splitter 2 of this implementation structure does not reflect the light that is transmitted to the side surface 21 of the first beam splitter from the light after the initial distribution to the second beam splitter 3, but directly passes through the side surface 21 of the first beam splitter. The light is reflected into the air; furthermore, the light directly transmitted to the upper surface 22 of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com