Flexible LED soft lamp band and production process thereof

A production process and technology of flexible strips, which are applied in lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of breaking the lamp strip, difficult to solve the problem of light spots and glare, and reducing the qualified rate of products, and achieve enhanced The effect of pulling the tensile strength, reducing the spot and glare, and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

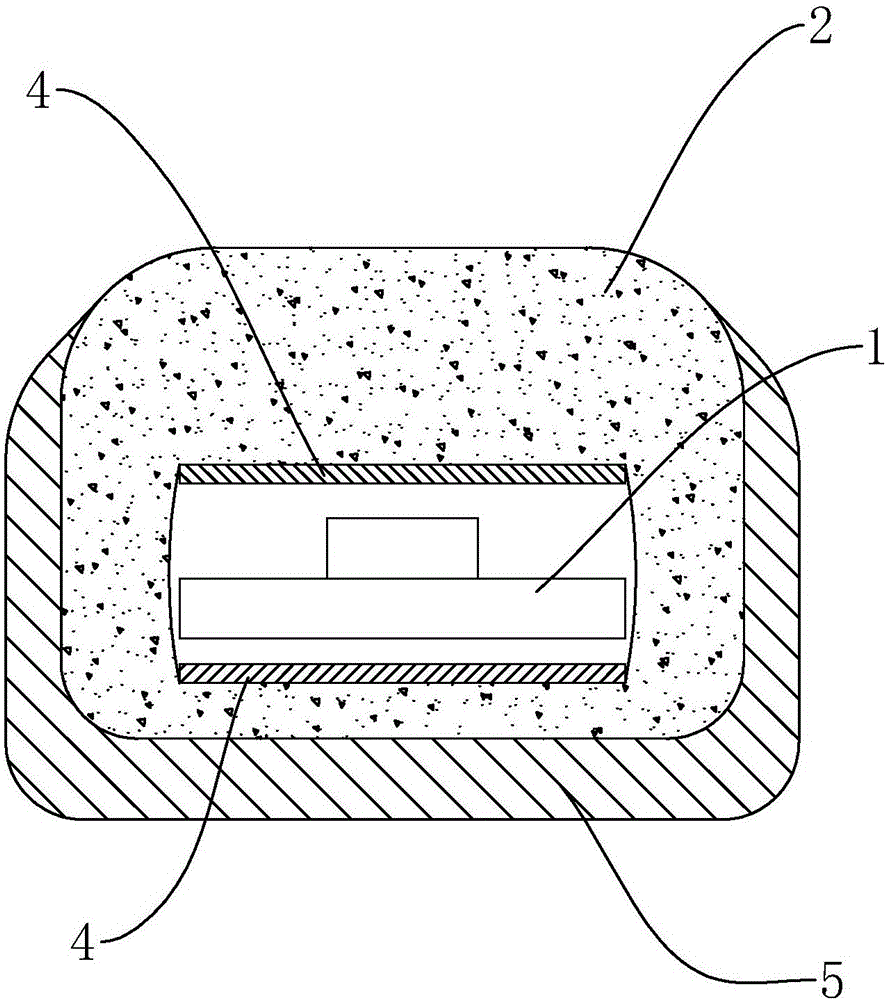

[0020] refer to figure 1 , figure 1 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, a flexible LED flexible light strip includes a light strip main body 1 and a glue filling layer 2. The light strip main body 1 includes a flexible substrate and is arranged on the flexible substrate. LED chips and circuit components, above the main body of the light strip 1 is arranged an upper flexible belt 3 along the length direction of the main body 1 of the light strip. 3. It can strengthen the traction and tensile strength of the main body 1 of the light strip, which is not easy to be broken during the rubber extrusion or extrusion process, and can also protect the LED chips and circuits on the main body 1 of the light strip during the extrusion or extrusion process. Components have the effect of high temperature insulation and improve the pass rate of products.

[0021] Preferably, the glue filling layer 2 is a diffusion t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com