Self-heating molding repair device of medium-temperature curing composite material

A composite material and self-heating technology, applied in heat exchange materials, thermal insulation, heat exchange equipment, etc., can solve the problem of self-heating related technologies that do not meet the requirements of composite material molding, repair and curing, difficult to discharge exothermic gas products, self-heating The problem of uneven mixing of materials can achieve the effect of simple structure, good thermal insulation effect and high mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

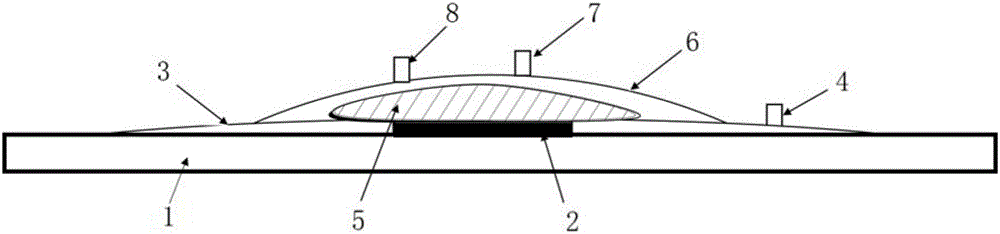

[0028] as attached figure 1 As shown, a medium-temperature curing composite material self-heating forming repair device of the present invention includes a vacuum pressure layer and a heating layer assembly that press the epoxy resin-based composite material patch on the surface of the repaired composite material structure.

[0029] The vacuum pressure layer includes a high temperature resistant film and an air suction port installed on the high temperature resistant film, and the air suction port is a one-way valve. The material of the high temperature resistant film is PET film.

[0030] The heating layer assembly includes a self-heating material layer composed of a solid part of the self-heating material, an insulation layer that attaches the self-heating material layer to the outer surface of the vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com