Bake-free casting material for ladle online roaster cladding lining and preparation method thereof

A roaster and castable technology, applied in the field of non-metallic refractory materials, can solve the problems of poor thermal stability, castable shedding and melting loss of the steel shell and cover lining, and achieve high bonding strength and thermal shock resistance Good performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A non-bake castable for the inner lining of the ladle on-line roaster cover, which consists of the following materials by weight percentage:

[0029] 20% of sintered mullite with 5mm≦particle size2 o 3 Differential 6.0%, silicon micropowder particle size ≦0.047mm 4.0%, metal aluminum powder particle size ≦0.165mm 3.5%, pure calcium aluminate cement 3.0%, heat-resistant steel fiber 2.5%.

[0030] The sintered mullite is selected from the grade M70, its AI 2 o 3 The content is 70.1%, SiO 2 The content is 27.6%, Fe 2 o 3 The content is 0.60%, R 2 The O content is 0.19%, and the bulk density is 2.95g.cm -3 , the apparent porosity is 1.53%, the water absorption is 0.4%, and the refractoriness is >1790°C.

[0031] The andalusite, its AI 2 o 3 The content is 58.15%, Fe 2 o 3 The content is 0.83%, R 2 The O content is 0.41%, the linear expansion rate at 1000°C is 1.16%, and the refractoriness is >1830°C.

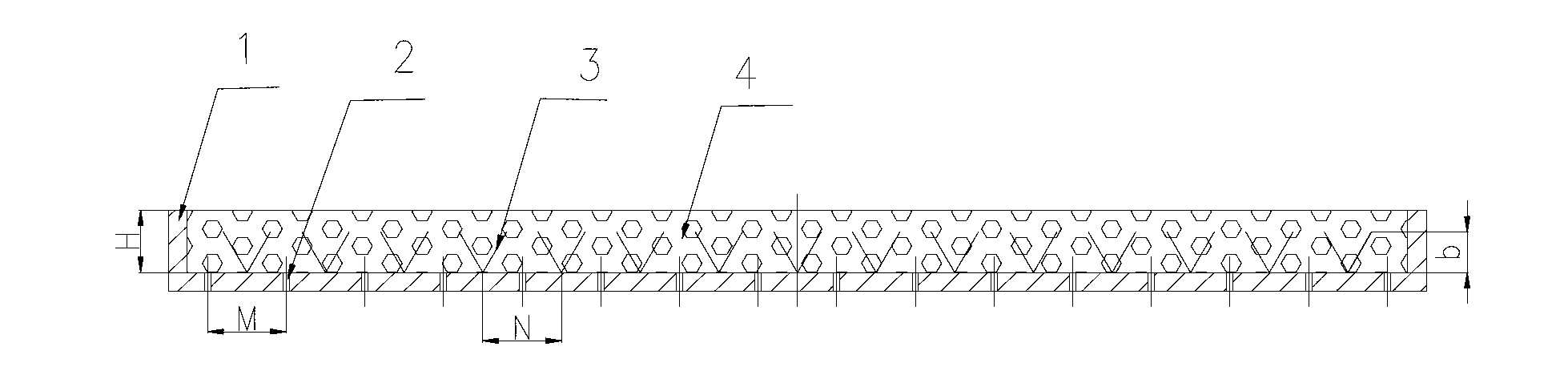

[0032] The heat-resistant steel fiber has a cross-section of ...

Embodiment 2

[0040] Others are the same as embodiment 1, the difference is:

[0041] A non-bake castable for the inner lining of the ladle on-line baker, which is composed of the following materials by weight percentage: 25% of sintered mullite with a particle size of 5mm ≤ 8mm, sintered mullite with a particle size of 3mm ≤ 5mm Sintered mullite 12%, 1mm≦particle size2 o 3 Differential 7.0%, silica powder with particle size ≦0.047mm 2.0%, metal aluminum powder with particle size ≦0.165mm 4.0%, pure calcium aluminate cement 3.5%, heat-resistant steel fiber 1.5%.

[0042] The sintered mullite is selected from the grade M73, whose AI 2 o 3 The content is 73.2%, SiO 2 The content is 21.9%, Fe 2 o 3 The content is 1.25%, R 2 The O content is 0.25%, and the bulk density is 2.91g.cm -3 , the apparent porosity is 2.91%, the water absorption is 1.0%, and the refractoriness is >1790°C.

[0043] The andalusite, its AI 2 o 3 The content is 55.69%, Fe 2 o 3 The content is 0.37%, R 2 The O ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com