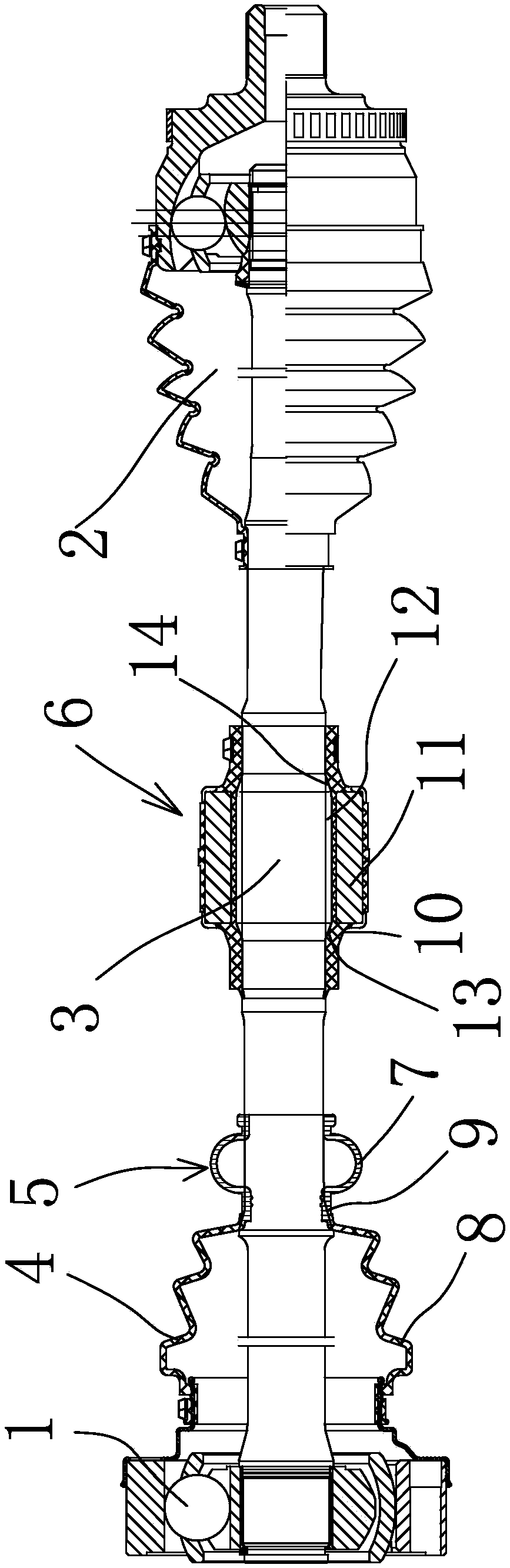

A drive shaft assembly vibration damping mechanism

A vibration damping mechanism and drive shaft technology, which is applied in the direction of couplings, mechanical equipment, elastic couplings, etc., can solve the problems of dust and other impurities entering, no buffer space, and dust-proof sealing covers falling off and cracking, etc., to achieve enhanced Stability, fall-off prevention, impact reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Buffering and damping adjustment part 7 The ratio of raw material components is as follows in parts by weight: 30 parts of neoprene rubber, 2 parts of polystyrene, 10 parts of di-n-octyl tin dithioglycolate, 8 parts of talcum powder, chlorinated paraffin 1 part of chlorofluoromethrin, 15 parts of anhydrous calcium chloride, 10 parts of acetyl triethyl citrate, 5 parts of iron oxide red, 7 parts of glycerin triacetate, 2 parts of fly ash, 6 parts of composite filler, black soil 4 parts. 1. Rubber mixing process

[0048] 1. Ingredients: Before ingredients, all kinds of powdery compounding agents that are easy to absorb moisture should be dried in an oven. They can be used only when they feel dry, soft and not agglomerated. Those with large lumps should be crushed. According to this formula, "one time Matching method "matching foot.

[0049] 2. Mixing: The coarse material should be stirred evenly, and the fine material should be placed separately after mixing, and moistu...

Embodiment 2

[0062] Buffering and damping adjustment part 7 The ratio of raw material components is as follows in parts by weight: 30 parts of neoprene rubber, 2 parts of polystyrene, 10 parts of di-n-octyl tin dithioglycolate, 8 parts of talcum powder, chlorinated paraffin 1 part of chlorofluoromethrin, 15 parts of anhydrous calcium chloride, 10 parts of dioctyl sebacate, 2.5 parts of zinc oxide, 2.5 parts of magnesium oxide, 7 parts of triacetin, 2 parts of fly ash, composite filler 6 parts, black soil 4 parts.

[0063] 1. Rubber mixing process

[0064] 1. Ingredients: Before ingredients, all kinds of powdery compounding agents that are easy to absorb moisture should be dried in an oven. They can be used only when they feel dry, soft and not agglomerated. Those with large lumps should be crushed. According to this formula, "one time Matching method "matching foot.

[0065] 2. Mixing: The coarse material should be stirred evenly, and the fine material should be placed separately after m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com