High-precision bearing with large length-to-diameter ratio and its manufacturing method, and water pump rotor and its manufacturing method

A large aspect ratio, water pump rotor technology, applied in the direction of bearings, manufacturing tools, shafts and bearings, etc., can solve the problems of non-dry friction, large bearing tolerance, large bearing friction surface, etc., to reduce working temperature, reduce wear, Good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

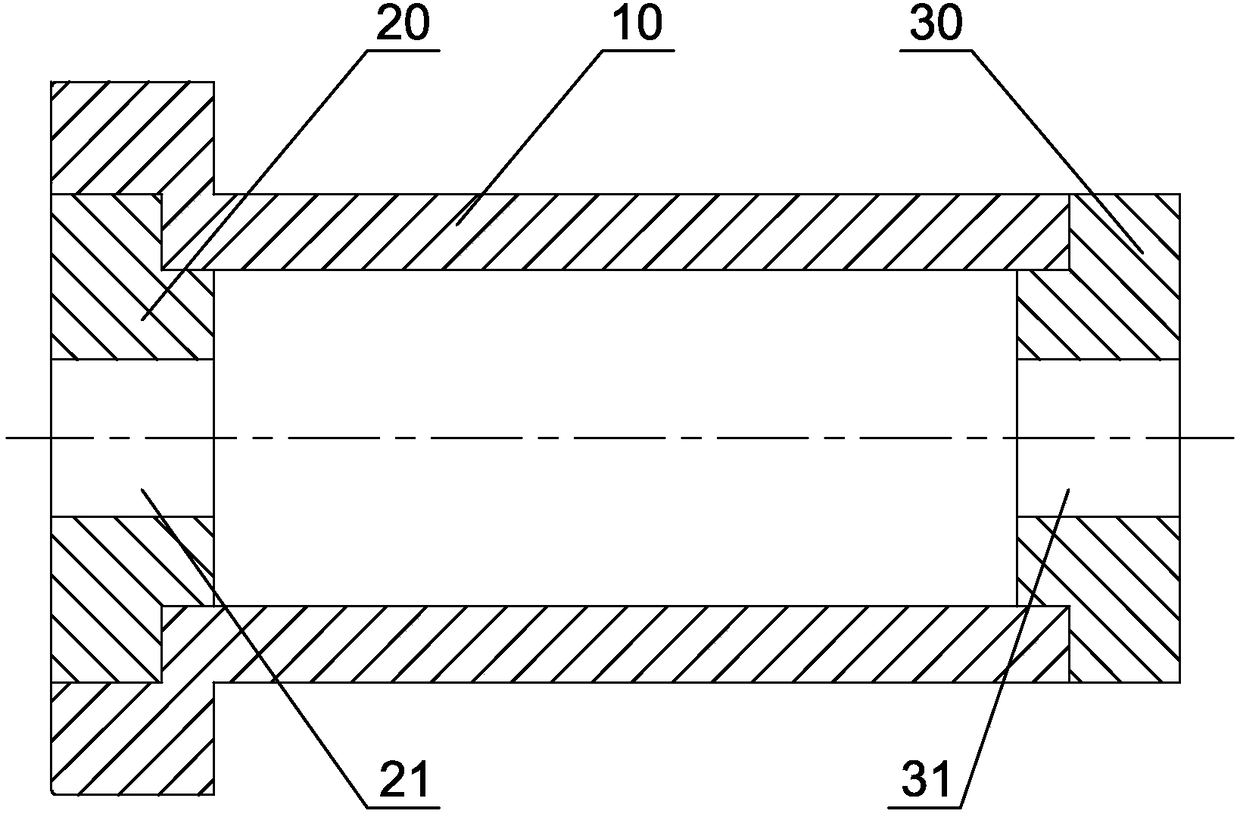

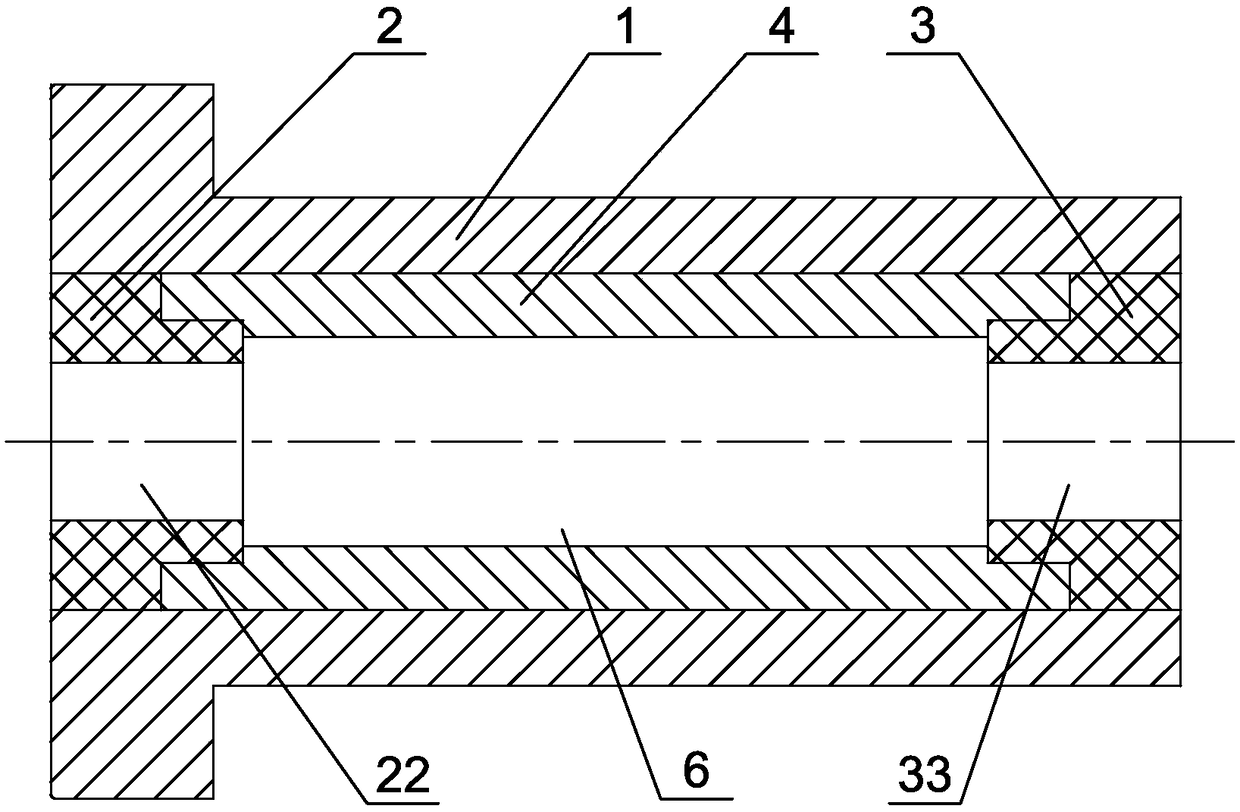

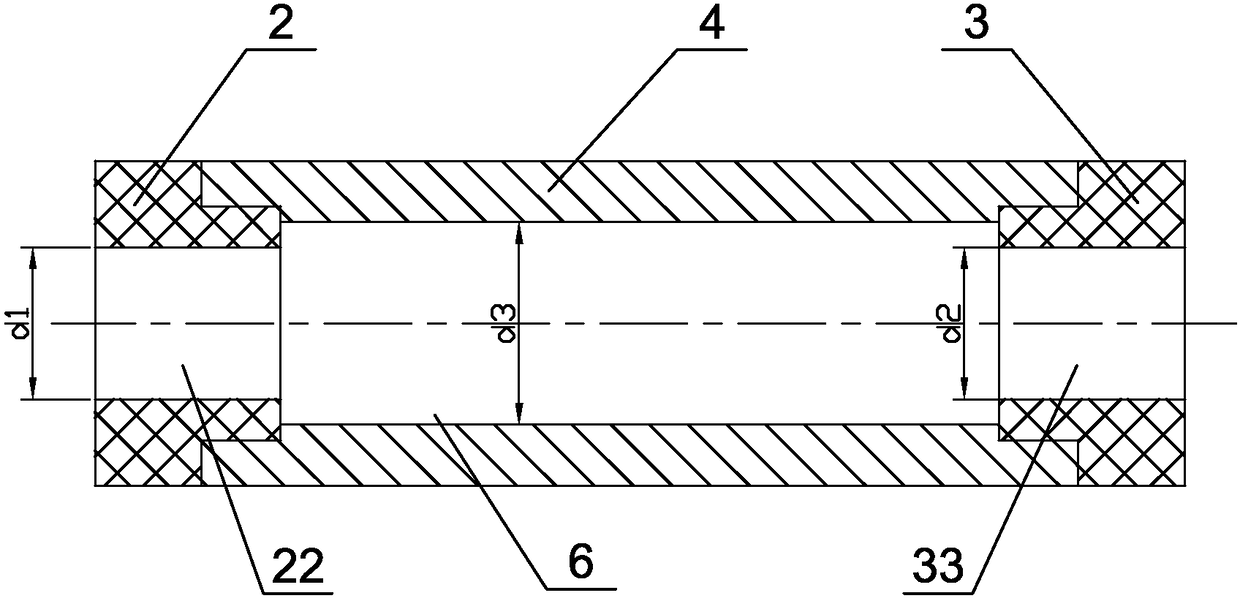

[0037] Such as figure 2 , image 3 As shown, the water pump rotor in this embodiment includes a rotor body 1 and a high-precision bearing with a large aspect ratio; wherein, the high-precision bearing with a large aspect ratio includes a first friction part 2 and a second friction part 3 located at both ends, located at The structural connection part 4 connecting the first friction part 2 and the second friction part 3 in the middle part, the center of the first friction part 2 is provided with a first shaft hole 22, and the second friction part 3 The center of the second shaft hole 33 is provided, and the two ends of the first friction part 2, the second friction part 3 and the structural connection part 4 are respectively connected and fixed into one body through interference fit. In this embodiment, The connection is stepped, and the first shaft hole 22 and the second shaft hole 33 are finally shaped by internal grinding and precision machining to ensure that they are coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com