Explosion venting bolt and explosion venting window with explosion venting bolt

A technology for venting windows and bolts, applied in the field of venting windows, can solve the problems of difficulty in quickly achieving pressure relief, easy to explode, etc., and achieve the effects of strengthening strength, avoiding huge losses, and reducing losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

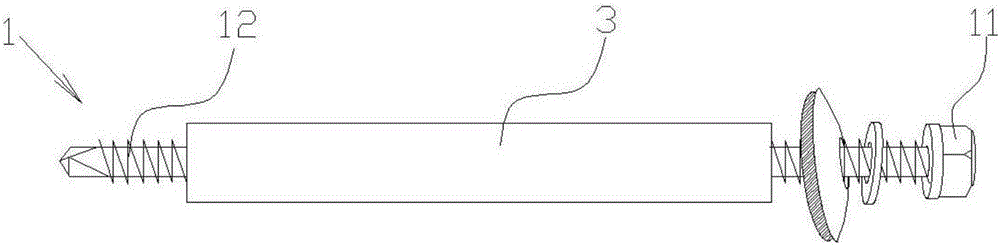

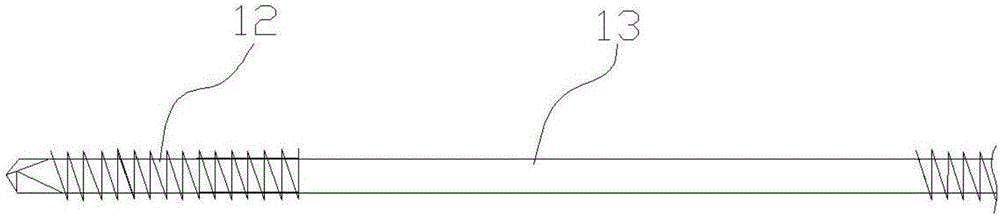

[0046] Figure 5 and Figure 6 It schematically shows that an explosion venting bolt disclosed by the present invention is used in a rock wool sandwich steel plate explosion venting wall.

[0047] Such as Figure 5 and Figure 6 As shown, the explosion venting wall 71 of rock wool sandwich steel plate is fixed on the wall beam 81 through a kind of explosion venting bolt disclosed by the present invention. The inner diameter of the explosion-venting bolt nut 11 is larger than the outer diameter of the explosion-venting bolt nut 11. The screw rod 12 of the explosion-venting bolt passes through the through hole on the rock wool sandwich steel plate explosion-venting wall 71, and passes through the self-tapping function of the self-tapping head at the end of the screw rod. Pass through the wall beam 81 and be fixedly connected with the wall beam 81. The metal sleeve 3 is located in the through hole of the rock wool sandwich steel plate explosion vent wall 71, and the cooperatio...

Embodiment 2

[0049] Figure 7 and Figure 8 It schematically shows that an explosion venting bolt disclosed by the present invention is used in a single-layer color steel plate explosion venting wall.

[0050] Such as Figure 7 and Figure 8 As shown, the single-layer color steel plate explosion-venting wall 72 is fixed on the wall beam 82 through a kind of explosion-venting bolt disclosed by the present invention. In this embodiment of the present invention, the single-layer color steel plate explosion-venting wall 72 and the wall beam 82 There are thermal insulation cotton layers 9 attached between them, and the thermal insulation cotton layers 9 play the role of thermal insulation and sound insulation. In addition, preferably, a stepped side plate 91 is also provided between the single-layer color steel plate explosion venting wall 72 and the insulation cotton layer 9, such as Figure 6 As shown, the side plate 91 is in a stepped shape and is located at the joint position of two sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com