Mining procedure of inclined seam narrow and long strip mine

An open-pit mine, narrow and long technology, applied in ground mining, earth square drilling, underground mining, etc., can solve the problems of poor slope stability in inner dumps, slow inner drainage space, large ore and rock transportation distance, etc., and achieve resource utilization. Improvement of recovery rate and comprehensive economic benefits, reduction of ore and rock transportation distance, and balanced production stripping ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

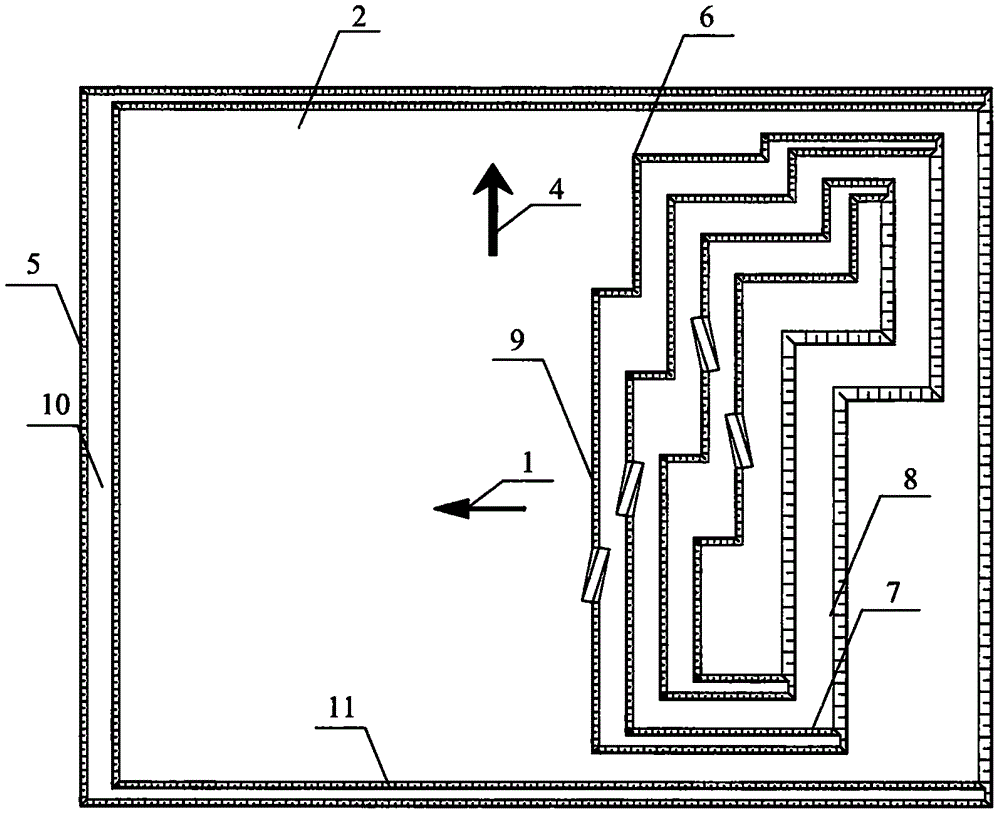

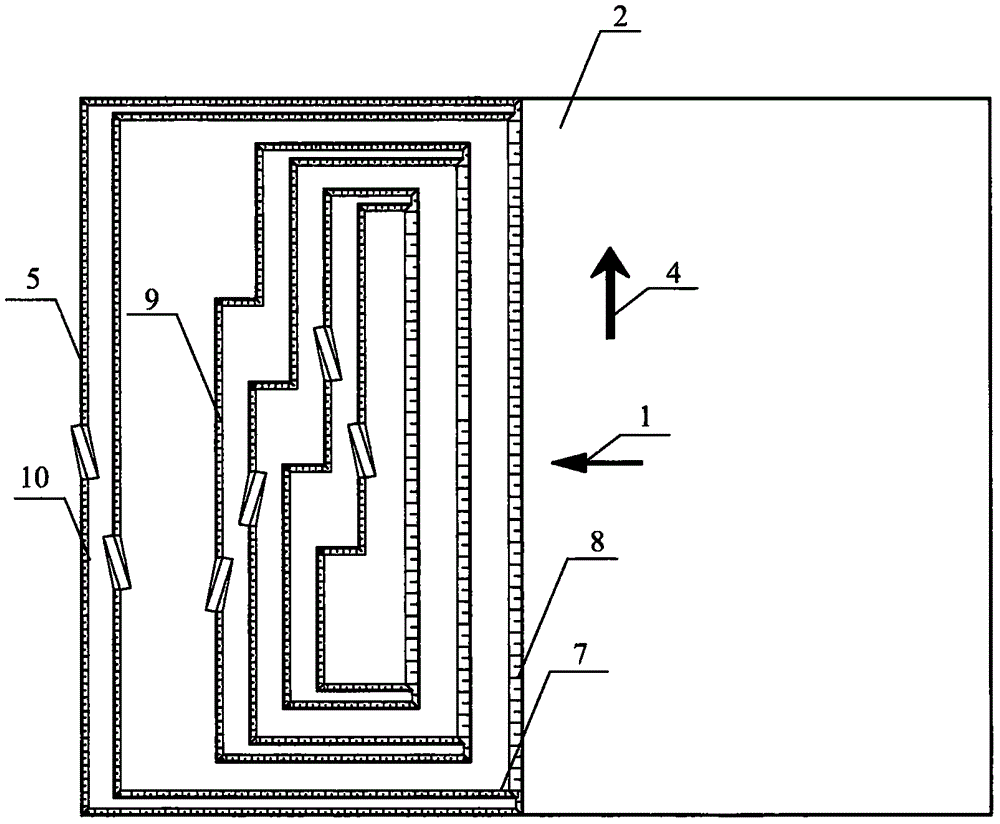

[0020] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] The mining program of the narrow and long open-pit mine of inclined coal seam of the present invention, concrete steps are as follows:

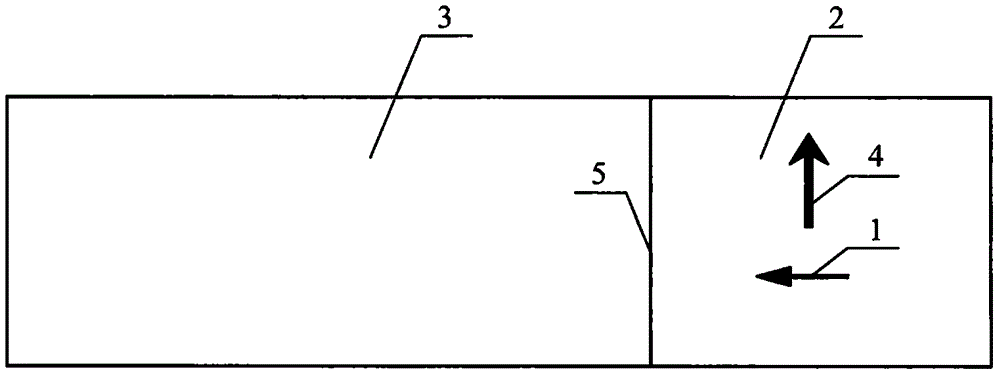

[0022] a. If figure 1 As shown, the open-pit mine is divided into two mining areas, the first mining area 2 and the second mining area 3, along the longitudinal direction 1, and the first mining area 2 is mined first;

[0023] b. In the first mining area 2, the working line is arranged along the vertical direction 1 in the early stage and advanced along the horizontal direction 4. Due to the small internal discharge space released in the early stage and the poor stability of the slope of the inner dump site, all the stripped objects are discharged outside or only a small amount of internal discharge;

[0024] c. When the upper step of the first mining area 2 reaches the limit, use the existing longitudinal worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com