Drill with open water hole

An open, water hole technology, used in construction and other directions, can solve the problems of reducing the service life of the drill bit, unreasonable hydraulic structure of the drill bit, etc., to achieve the effect of improving the hydraulic utilization rate, broadening the cleaning and cooling range, and increasing flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following non-limiting examples serve to illustrate the invention.

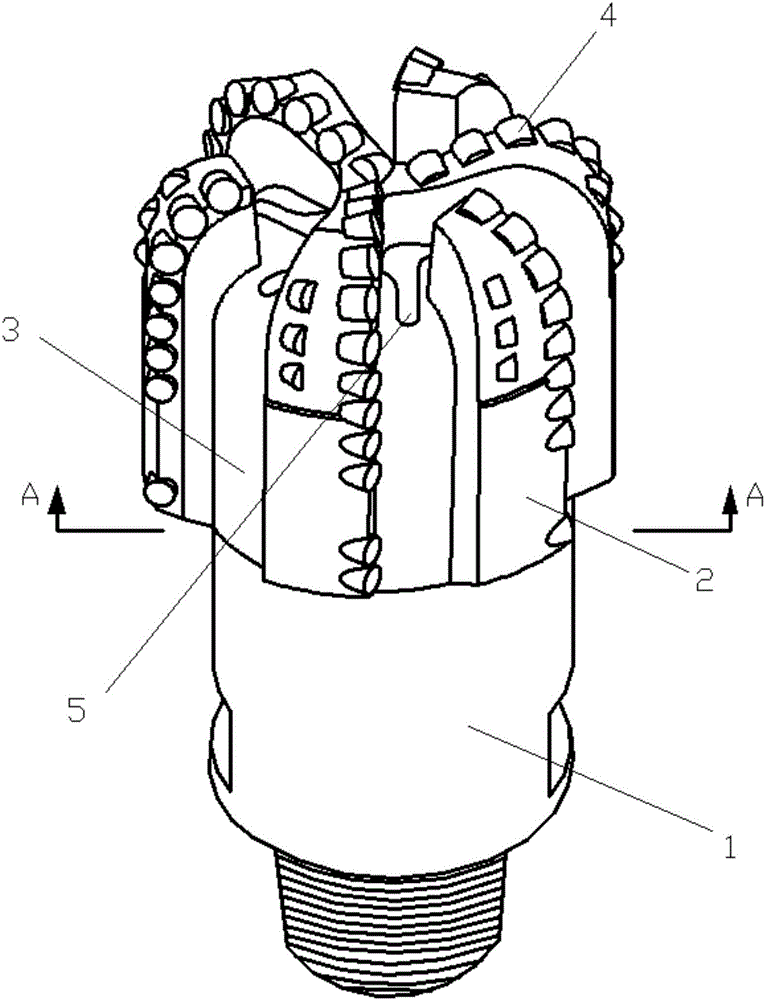

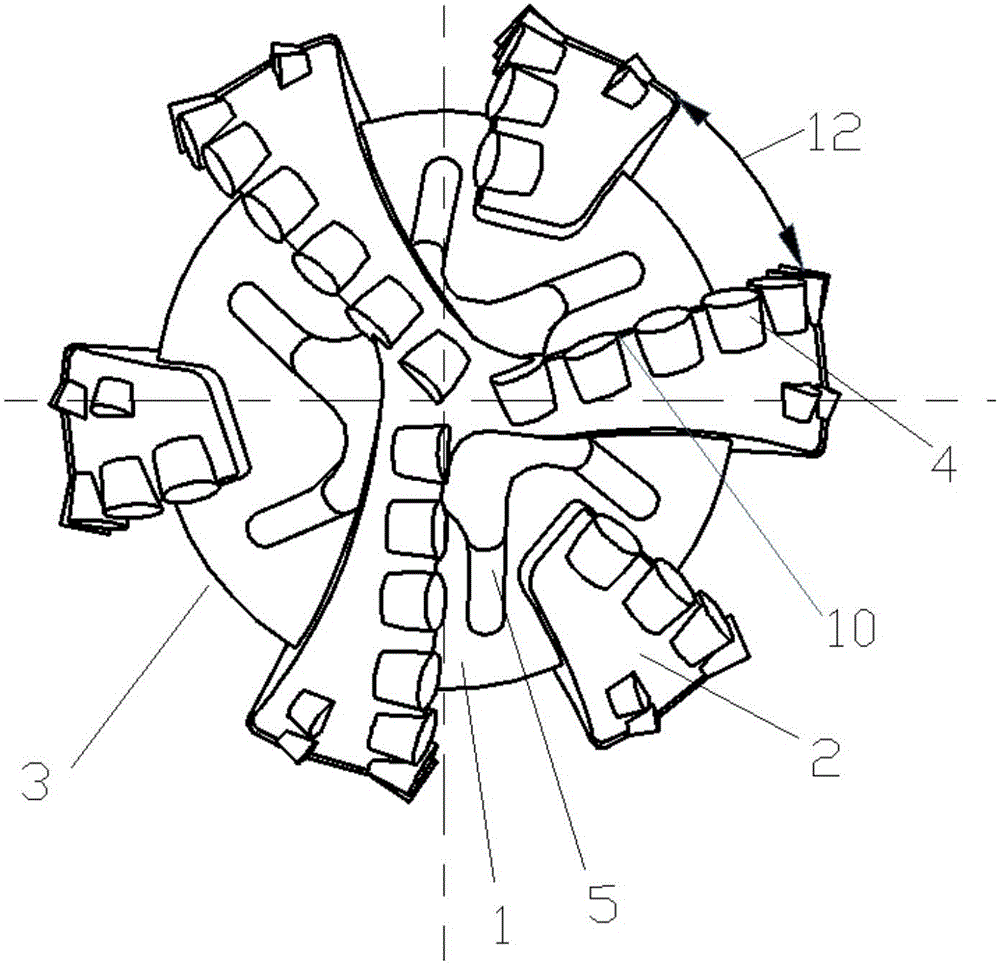

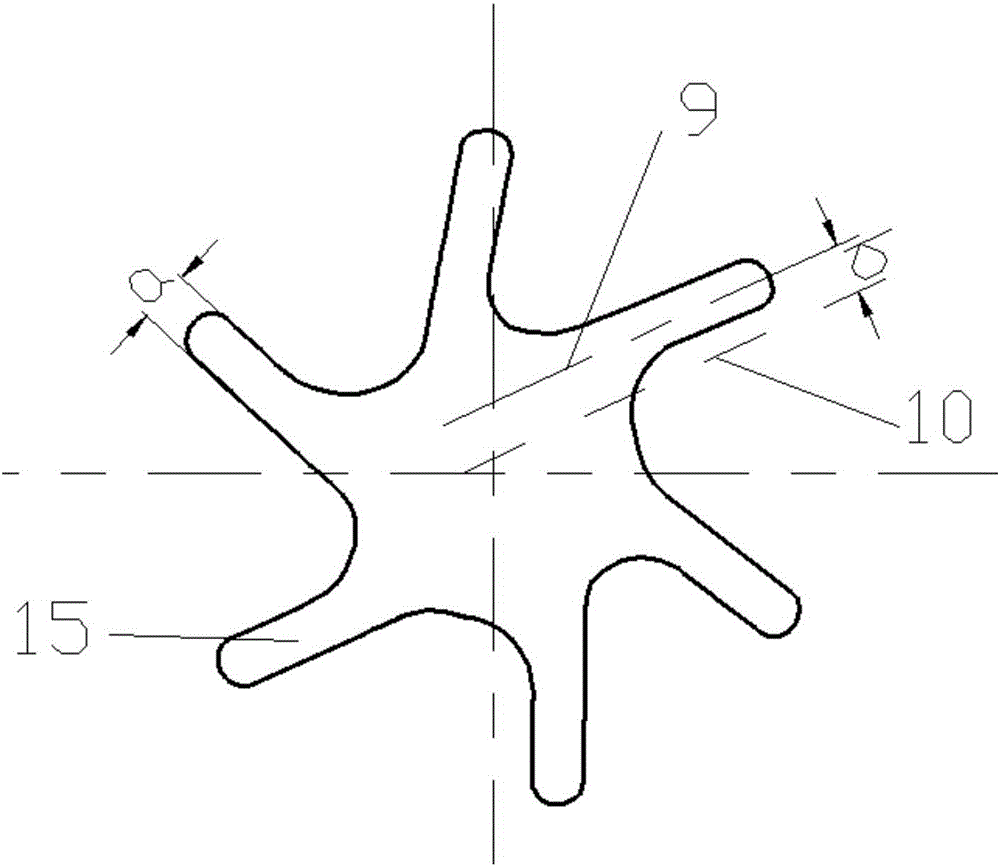

[0029] refer to Figures 1 to 6 As shown, a drill with an open water hole includes a drill body 1, a cutting structure 2, cutting teeth 4, a chip flute 3, an inner flow channel 11 and a water hole 5, and the cutting structure 2 is arranged on the drill body 1, The cutting teeth 4 are arranged on the cutting structure 2 , the inner flow channel 11 is arranged in the drill body 1 , the chip removal groove 3 is arranged between the cutting structures 2 , and the water hole 5 is arranged between the inner flow channel 11 and the chip removal groove 3 . Connecting the inner flow channel 11 and the chip removal groove 4, the feature of the present invention is that there is only one water hole 5, and the whole is in the shape of a large mouth and a small bottom (from Figure 4 , 5 From the perspective of the elevation / stereoscopic view, it means that the top is large and the bottom is small), and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com