Dual-cycle reverse osmosis device and reverse osmosis treatment method

A reverse osmosis device and double-circulation technology, applied in osmosis/dialysis water/sewage treatment, reverse osmosis, chemical instruments and methods, etc., can solve problems such as reverse osmosis membrane clogging and waste of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

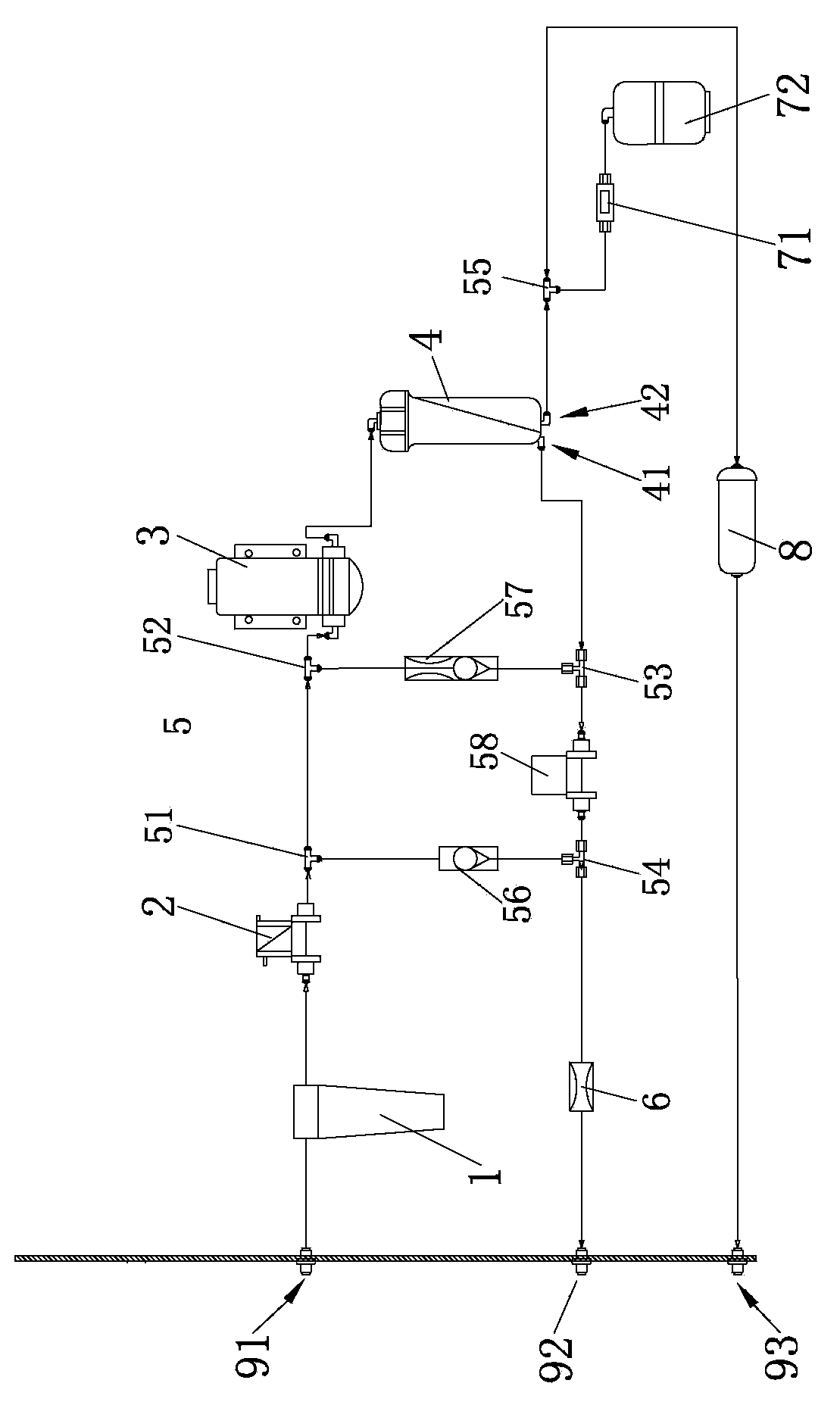

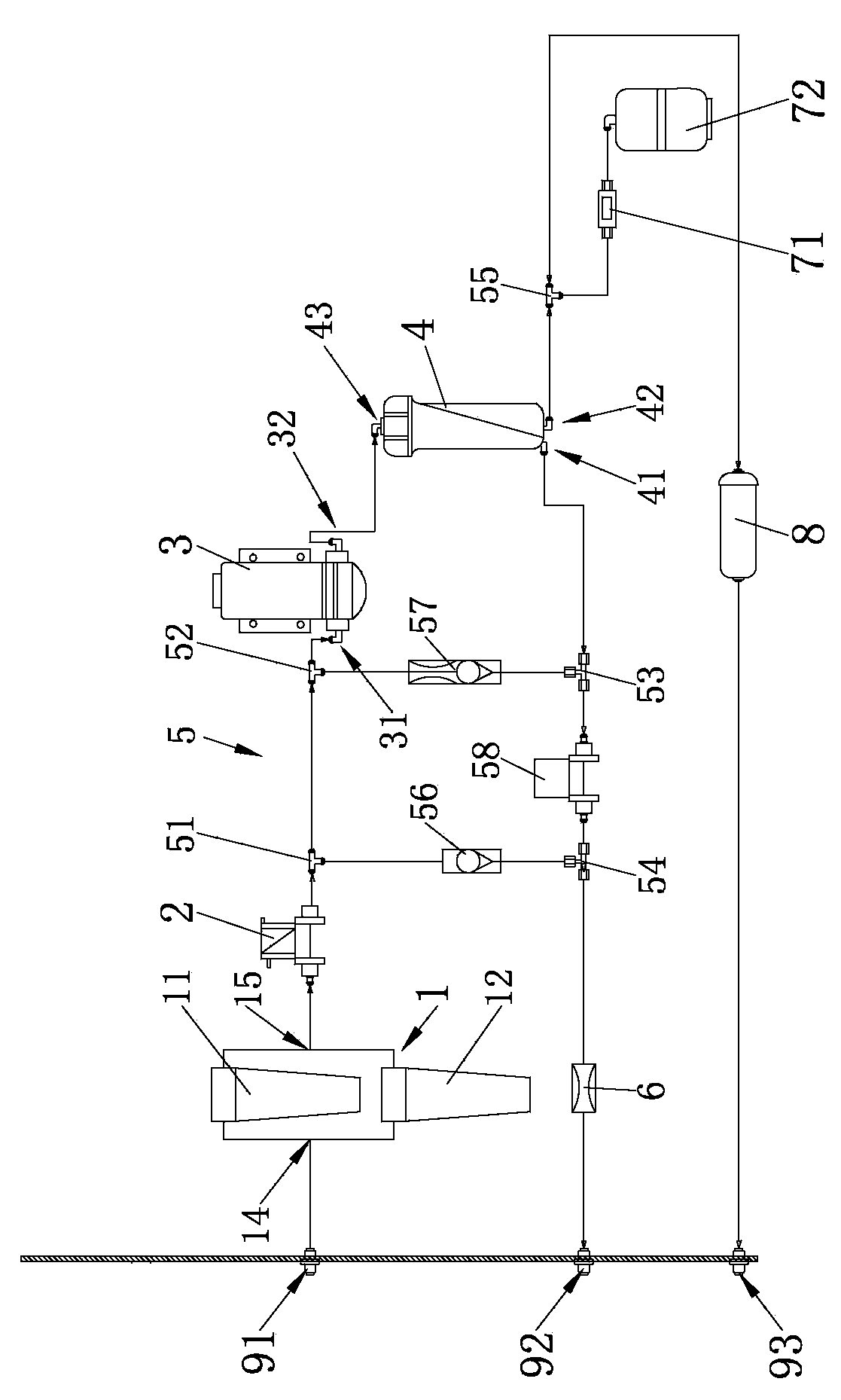

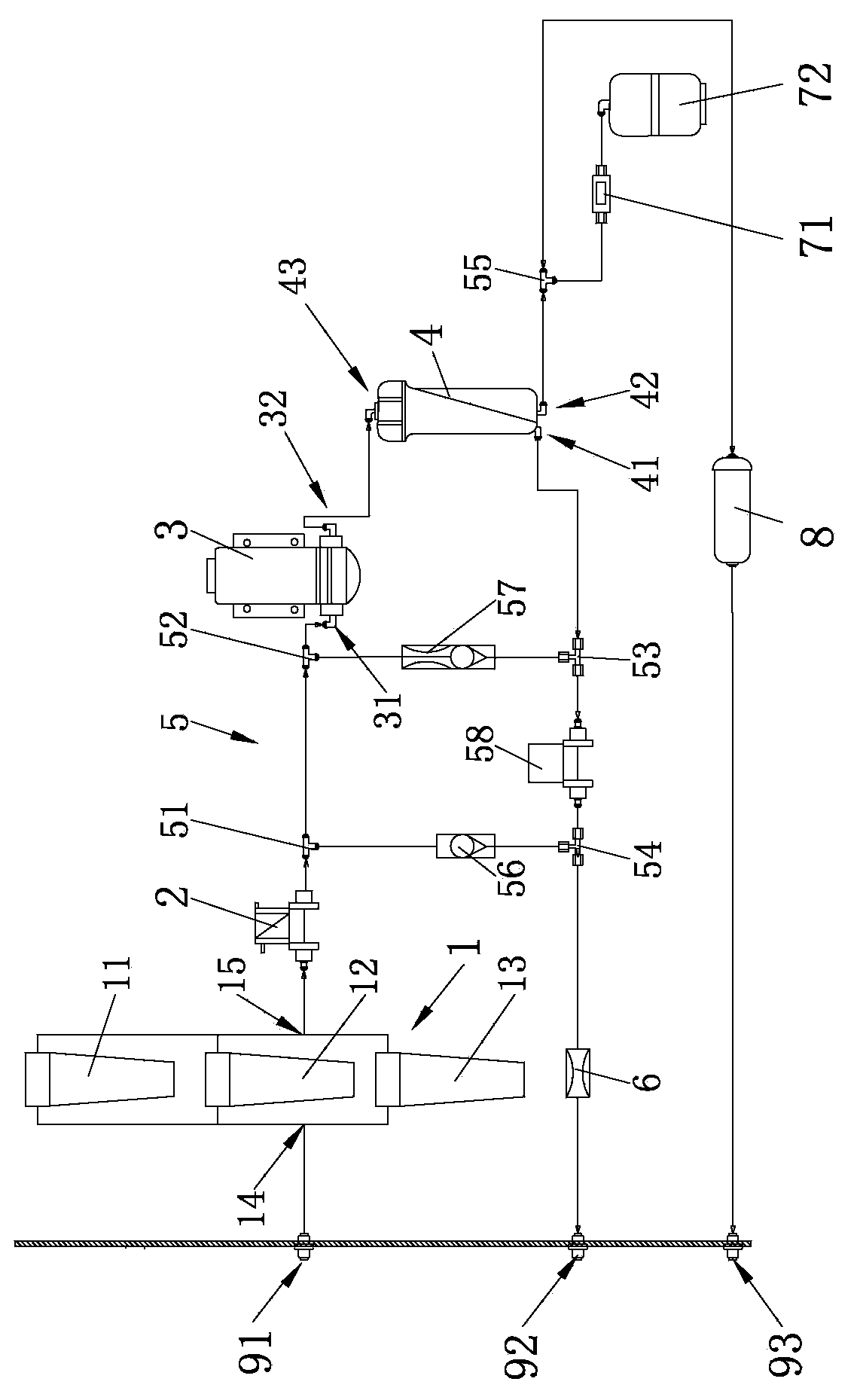

[0021] The present invention will be described in further detail below in conjunction with accompanying drawing:

[0022] Please refer to the accompanying drawings, the double-cycle reverse osmosis device includes:

[0023] The pre-treatment device 1, the water inlet solenoid valve 2, the booster device 3, the concentrated water port 41 of the post-processing device 4, the double-cycle water-saving circuit 5, the throttling device 6 and the concentrated water discharge are connected by the water inlet pipe 91 through the pipeline. A small circulation loop formed between the mouths 92; The through pipe 55 is divided into two routes, one of which flows into the pure water storage tank 72 through the high pressure switch 71;

[0024] In this embodiment, the double-cycle water-saving circuit 5 is composed of the first three-way pipe 51, the second three-way pipe 52 and the concentrated water port of the post-processing device 4 provided between the water inlet solenoid valve 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com