Underground coal mine roadway bottom plate anchor rod drilling device with self-moving diagonal cross location function

A technology of diagonally intersecting and drilling devices, which is applied in the direction of supporting devices, bolt installation, drilling equipment and methods, etc., and can solve problems such as low efficiency, slow drilling and bolt installation speed, and large consumption of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

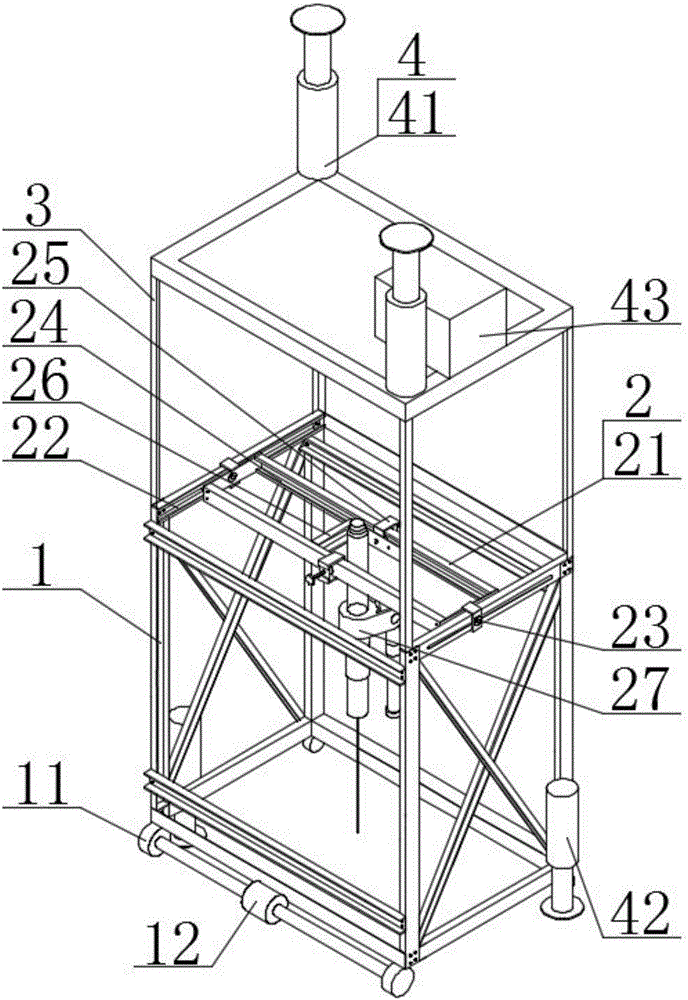

[0019] like figure 1 As shown, the coal mine underground self-moving diagonal cross positioning roadway floor bolt drilling device includes an underframe 1, a working part 2, an upper frame 3 and a device positioning part 4.

[0020] The upper frame 3 is fixedly installed on the bottom frame 1, and the bottom end of the bottom frame 1 is provided with at least one set of rollers including a coaxial driving wheel 11, and the driving wheel 11 is provided with a driving hydraulic motor 12.

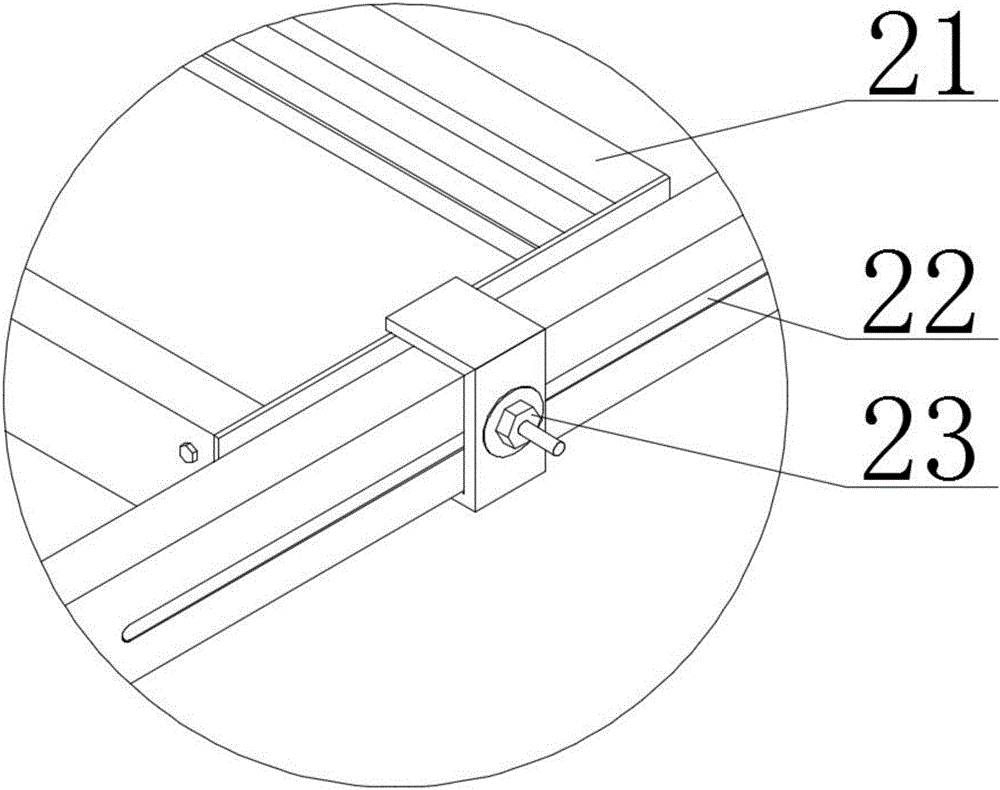

[0021] The working part 2 is installed on the chassis 1, including a body 21, front and rear guide slots 22, front and rear positioning locking nuts 23, left and right guiding slots 24, left and right positioning locking nuts 25, drilling rig mounting frame 26 and drilling rig 27 The main body 21 is a rectangular frame structure, and its left and right end faces are erected on the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com