Manufacturing method of titanium alloy sound insulation door

A titanium alloy and sound-proof door technology, which is applied to sound-proof doors/windows, chemical instruments and methods, door leaves, etc., can solve the problems of poor sound-proof effect of metal doors, achieve strength and fire-proof effects, enhance overall strength, and heat resistance good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment 1

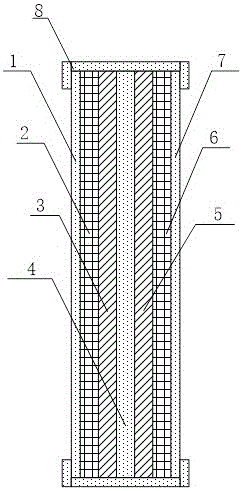

[0027] A titanium alloy soundproof door, including a door frame and a door leaf, the door leaf includes an inner door panel (1) and an outer door panel (7), and a frame (8) connecting the inner door panel and the outer door panel, and the inner door panels are arranged sequentially from the inside to the outside (1), the first fireproof layer (2), the first soundproof layer (3), the core layer (4), the second soundproof layer (5), the second fireproof layer (6), the outer door panel (7), all The inner door panel (1) and the outer door panel (7) are both made of titanium alloy. First, the first fireproof layer (2), the first sound insulation layer (3), the core layer (4), and the second Two sound insulation layers (5), the second fire protection layer (6), the outer door panel (7), and then use the frame to fix the inner door panel and the outer door panel.

[0028] Its preparation method is:

[0029] The inner door panel, outer door panel and frame are all made of titanium al...

Embodiment 2

[0043] Among them, the inner door panel, the outer door panel and the frame are all made of titanium alloy plate, and the elemental composition of the titanium alloy plate is: Ni3.9%, Cr2.66%, Al1.76%, Mo0.52%, Fe0.132%, Mg0.125%, Cu0.34%, V0.27%, Sn0.042%, Y0.036%, Bi0.32%, Si0.014%, In0.038%, Pr0.033%, the balance is titanium and not Avoid non-metallic inclusions. The preparation method is as follows: first prepare the raw materials according to the proportion of the titanium alloy component elements, put the raw materials into the melting furnace for melting, and then pour them into the mold to form alloy ingots, and perform homogenization annealing on the above alloy ingots treatment, and then cooled with the furnace, the homogenized annealing temperature is 1080°C, and the holding time is 24 hours; the initial forging temperature for heating the above-mentioned annealed alloy ingot is 920°C, and the final forging temperature is 810°C. After forging, the alloy The ingot ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com