Wave roller and machining method of wave roller

A processing method and technology of wave rollers, which are applied in textile processing machine accessories, textiles and papermaking, and textile material processing, can solve the problem of affecting the support strength and runout accuracy of cloth guide rollers, insufficient infiltration of washing media and cloth, and manual grinding Treatment and other problems, to achieve the effect of improving the washing effect, convenient and fast processing, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

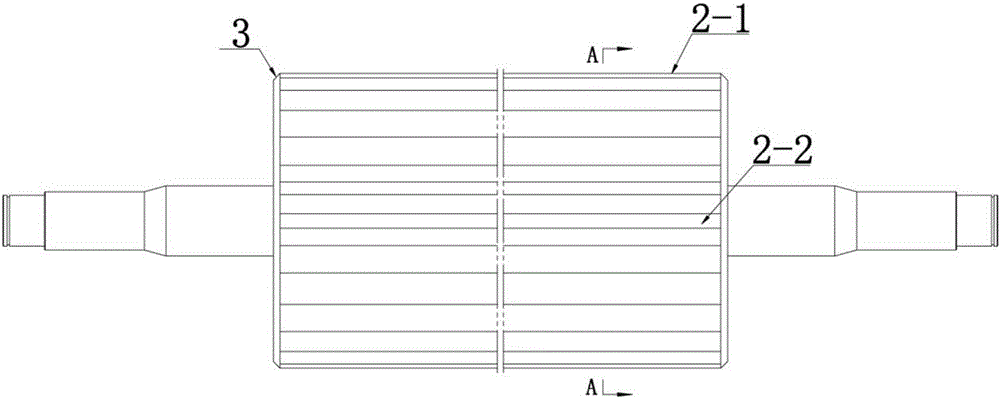

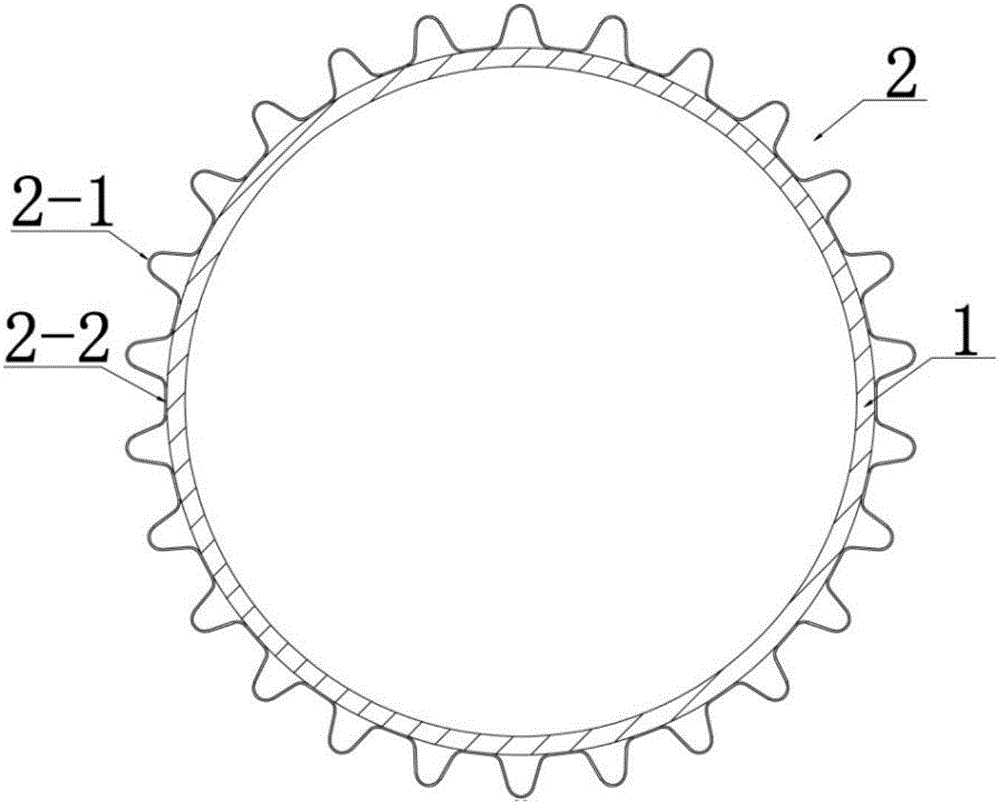

[0031] Such as figure 1 and figure 2 As shown, a wave roller includes a roller body 1, and the roller body is made of a stainless steel composite pipe. Protruding portions 2-1 uniformly distributed around the circumference and transition portions 2-2 connected between the bottoms of adjacent said protruding portions, said protruding portions and transition portions are integrally structured; the top of said protruding portions Arc-shaped.

[0032] The cylindrical cover roller is connected with the roller body through spot welding, and the two ends of the cylindrical cover roller are spot welded along the circumferential direction. Welding spots can also be set in the middle of the cylindrical cover roller. The position of the spot welding spot be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com