Equipment for non-shrink treatment of wool raw materials and products

An anti-shrinkage treatment and wool technology, which is applied in the treatment of textile materials, the configuration of equipment for processing textile materials, and the biochemical treatment of enzymes/microorganisms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

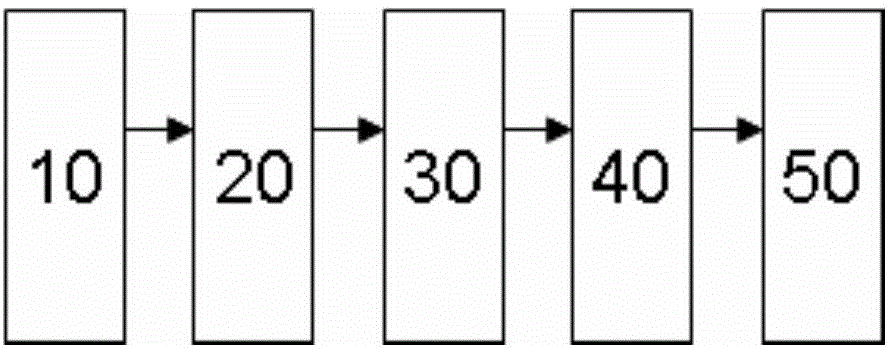

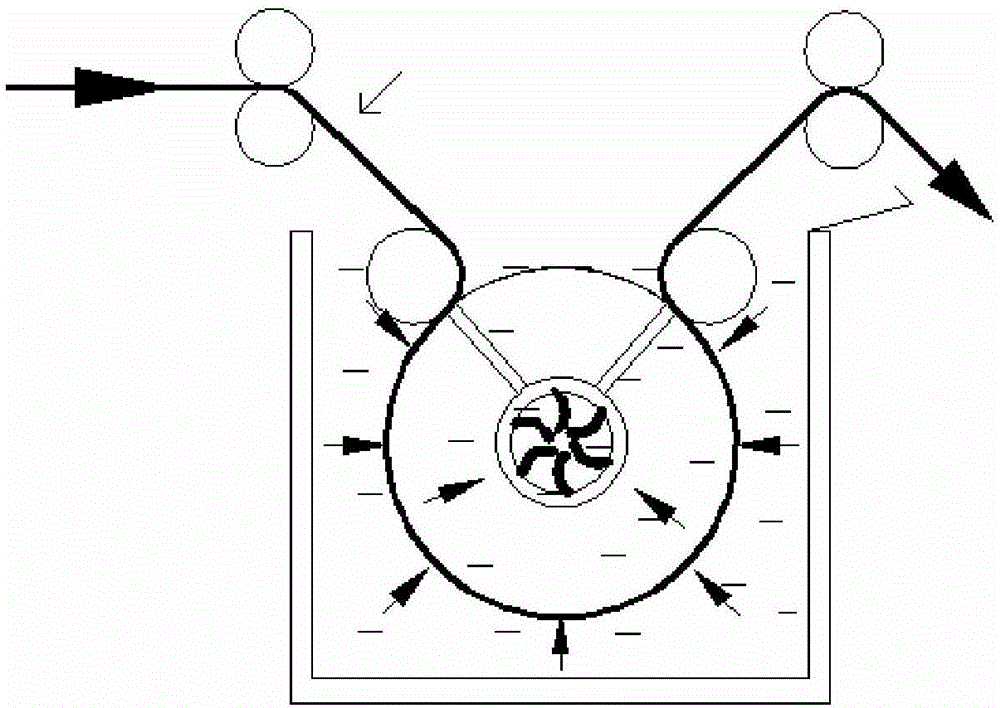

[0222] In this embodiment, the continuous process of five-fold padding is adopted to carry out chlorine-free anti-shrinkage treatment on the wool strips.

[0223] The whole wool wool strips to be processed, the specification is 70 pieces. The process includes the following steps:

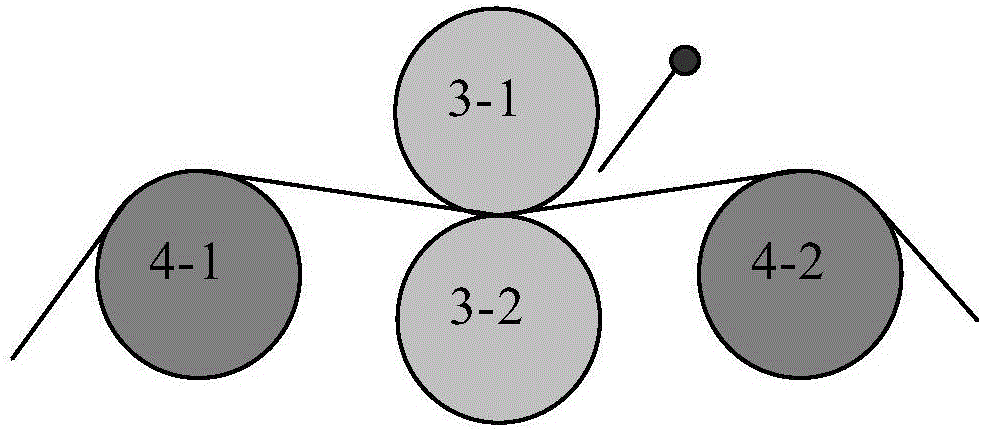

[0224] The first tank: padding treatment solution. The tank is 1 meter wide, 360 liters in volume and has a suction drum (type) washing tank (universal device) with a circumference of 1 meter. There is an automatic heating device (general device) in the suction drum tank, and the main components are: Alkali protease (alkali protease) 3g / L, three (3-hydroxypropyl) phosphine 3g / L (add non-ionic surfactant JFC 1g / L) efficient catalytic solution, pH is 7.2 (with disodium hydrogen phosphate and Sodium dihydrogen phosphate is a pH regulator), and the temperature is controlled at 50°C.

[0225] Lay the wool strips side by side evenly on the top rollers and enter the treatment liquid at a constant speed ...

Embodiment 2

[0241] In this example, a six-fold padding continuous process is used to perform chlorine-free anti-shrinkage treatment on the wool strips.

[0242] The whole wool wool strips to be processed, the specification is 56 pieces. The process includes the following steps:

[0243] The first tank: padding treatment solution. The tank is a suction drum tank with a width of 1 meter, a volume of 360 liters, and a circumference of one meter. There is an automatic heating device in the suction drum tank, and a liquid containing alkaline protease 3g / L, three (3-hydroxypropyl ) a high-efficiency catalytic solution of 3 g / L of phosphine, the pH is 7.4, and the controlled temperature is 50° C.

[0244] Spread the wool tops evenly on the top rollers side by side and enter the treatment solution at a constant speed of 3.8 m / min to completely wet the wool tops to ensure that the surface of each fiber in the wool tops is treated evenly and thoroughly; then pressurize The rollers pressurize the...

Embodiment 3

[0260] In this embodiment, the continuous process of five-fold padding is adopted to carry out chlorine-free anti-shrinkage treatment on the wool strips.

[0261] All wool wool strips to be processed, the specification is 90 counts. The process includes the following steps:

[0262] The first tank: padding treatment solution. The tank is a suction drum tank with a width of 1 meter, a volume of 360 liters and a circumference of one meter. There is an automatic heating device in the suction drum tank, and alkaline protease 3g / L, tris(3-carboxypropyl) Phosphine 3g / L, anhydrous calcium chloride 0.3g / L (adding non-ionic surfactant JFC 1g / L) high-efficiency catalytic solution, pH is 7.6 (regulate pH with appropriate amount of sodium carbonate or sodium hydroxide solution), control The temperature is 50°C.

[0263] Spread the wool tops evenly on the top rollers side by side and enter the treatment solution at a constant speed of 3.8 m / min to completely wet the wool tops to ensure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Powerful | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com