Polyphase structure high-grade pipeline steel original austenite grain boundary corrosion agent and application method

A technology of austenite grain boundary and multi-phase structure, which is applied in the field of corrosion agent for original austenite grain boundary of high-grade pipeline steel with multi-phase structure, can solve the problems of easy aging of reagents, low reproducibility, no consideration, etc., and achieve The effect of short corrosion time, convenient preparation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

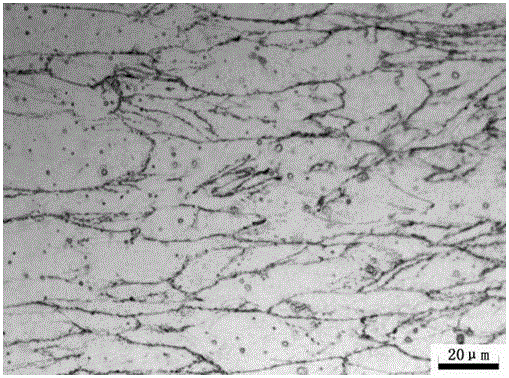

[0035] The high-grade X80 pipeline steel with multiphase structure is prepared from the following components in mass percentage: C: 0.04%, Si: 0.20%, Mn: 1.72%, Nb: 0.05%, Mo: 0.20%, Cu: 0.20%, Ni : 0.20%, Ti: 0.018%, Al: 0.01%,.

[0036] 1) Sample preparation process: The sample state is a high-grade pipeline steel sample that has been rolled by TMCP. First, the oxide skin on the surface of the sample is ground off on a grinder, and then the sample is firmly installed on Tegrapol-35 for automatic grinding. On the grinding head of the polishing machine, the corroded surface is automatically finely ground at 100#, 200#, 300#, 600#, 800#, 1000# according to the procedure, and then polished; the polishing agent is 1.5um diamond polishing paste, and the circulating water is used to Use as a lubricant; remove the automatically polished sample and lightly polish it on the silk fabric with clean water for 1 minute until the polished surface of the sample is inclined at an angle of 45...

Embodiment 2

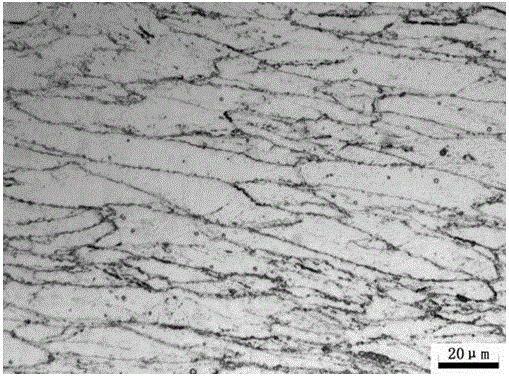

[0042] The high-grade X90 pipeline steel with multiphase structure is prepared from the following components in mass percentage: C: 0.05%, Si: 0.25%, Mn: 1.72%, Nb: 0.06%, Mo: 0.26%, Cu: 0.21%, Ni : 0.20%, Ti: 0.020%, Al: 0.02%,.

[0043] 1) Sample preparation process: The sample state is a high-grade pipeline steel sample that has been rolled by TMCP. First, the oxide skin on the surface of the sample is ground off on a grinder, and then the sample is firmly installed on Tegrapol-35 for automatic grinding. On the grinding head of the polishing machine, the corroded surface is automatically finely ground at 100#, 200#, 300#, 600#, 800#, 1000# according to the procedure, and then polished; the polishing agent is 1.5um diamond polishing paste, and the circulating water is used to Use as a lubricant; remove the automatically polished sample and lightly polish it on the silk fabric with water for 2 minutes until the polished surface of the sample is tilted at an angle of 45° to th...

Embodiment 3

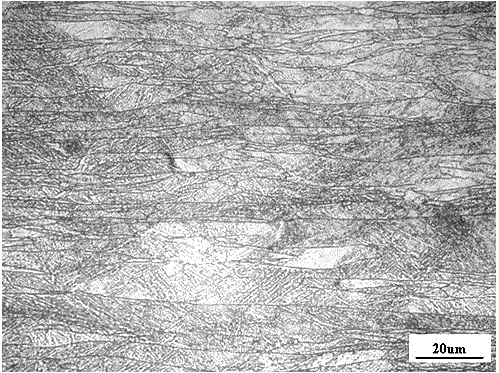

[0049] The high-grade X100 pipeline steel in this example is prepared from the following components by mass percentage: C: 0.06%, Si: 0.35%, Mn: 1.95%, Nb: 0.08%, Mo: 0.20%, Cu: 0.21%, Ni: 0.22%, Ti: 0.018%, V: 0.02%, Al: 0.02%.

[0050] 1) Sample preparation process: The sample state is a high-grade pipeline steel sample that has been rolled by TMCP. First, the oxide skin on the surface of the sample is ground off on a grinder, and then the sample is firmly installed on Tegrapol-35 for automatic grinding. On the grinding head of the polishing machine, the corroded surface is automatically finely ground at 100#, 200#, 300#, 600#, 800#, 1000# according to the procedure, and then polished; the polishing agent is 1.5um diamond polishing paste, and the circulating water is used to Use as a lubricant; remove the sample after automatic polishing, and then lightly polish it on the silk fabric with water for 1.5 minutes until the polished surface of the sample is inclined at an angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com