Multifunctional integrated gasification furnace with rotary furnace core air supply and simple scraper dust removal

A rotary, multi-functional technology, applied in gasification process, details of gasification device, manufacture of combustible gas, etc., can solve problems such as material layer bridging, uneven temperature distribution, high-temperature sintering, uneven material accumulation, etc., to achieve uniform lifting performance, uniform thickness, and improved operating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

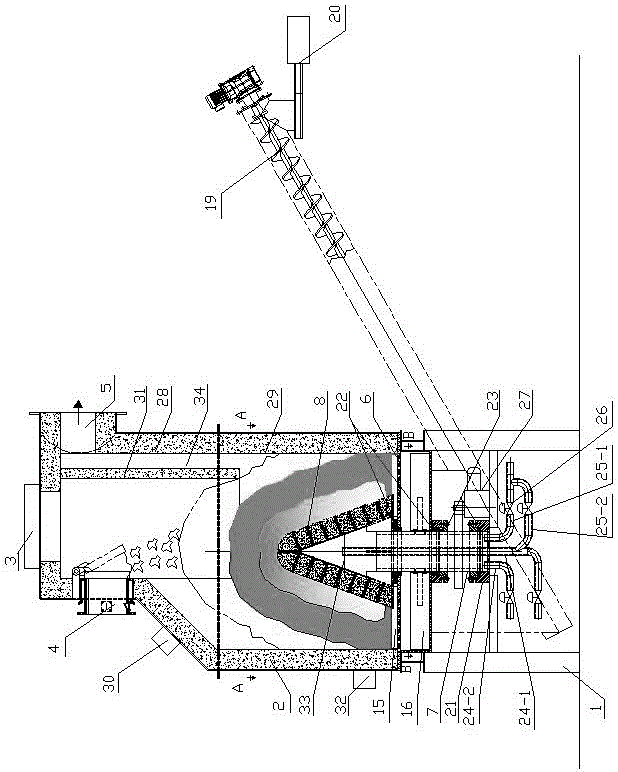

[0031] The invention discloses a multi-functional integrated gasification furnace with rotary furnace core air supply and simple scraper ash removal, which is used for harmless treatment of medical waste (hazardous waste) or pyrolysis gasification of domestic waste, recycling Utilize hydrocarbon resources in solid waste.

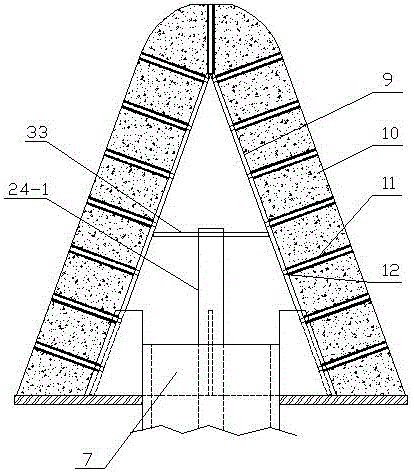

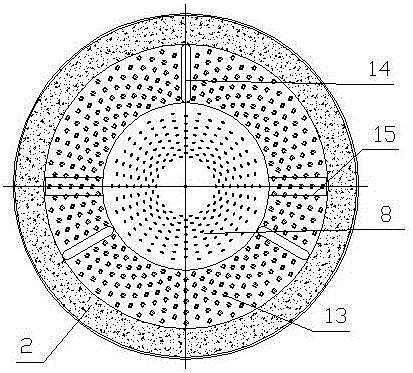

[0032] Such as figure 1 , 2 , 3, 4, and 5, the present invention includes a body of furnace base 1, a cylindrical body of furnace 2 is installed on the base 1, and the body of furnace 2 includes an upper body of furnace 28 and a lower body of furnace 29, which is convenient for the transportation of the gasifier For installation, flange connection is adopted between the upper furnace body 28 and the lower furnace body 29 , a high level material level detector 30 is installed on the upper furnace body 28 , and a low level material level detector 32 is also installed on the lower furnace body 29 .

[0033] The top of the furnace body 2 is provided with a fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com