Ultraviolet light curing antifog coating composition

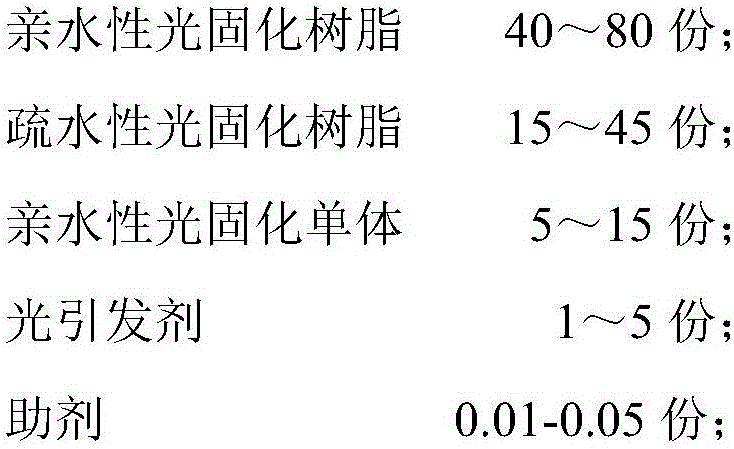

A technology of anti-fog coatings and compositions, applied in the direction of polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve problems such as long time required, complicated process, and inability to guarantee wear resistance, etc., to achieve cross-linking Increased density, improved wear resistance, and guaranteed continuous anti-fog performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

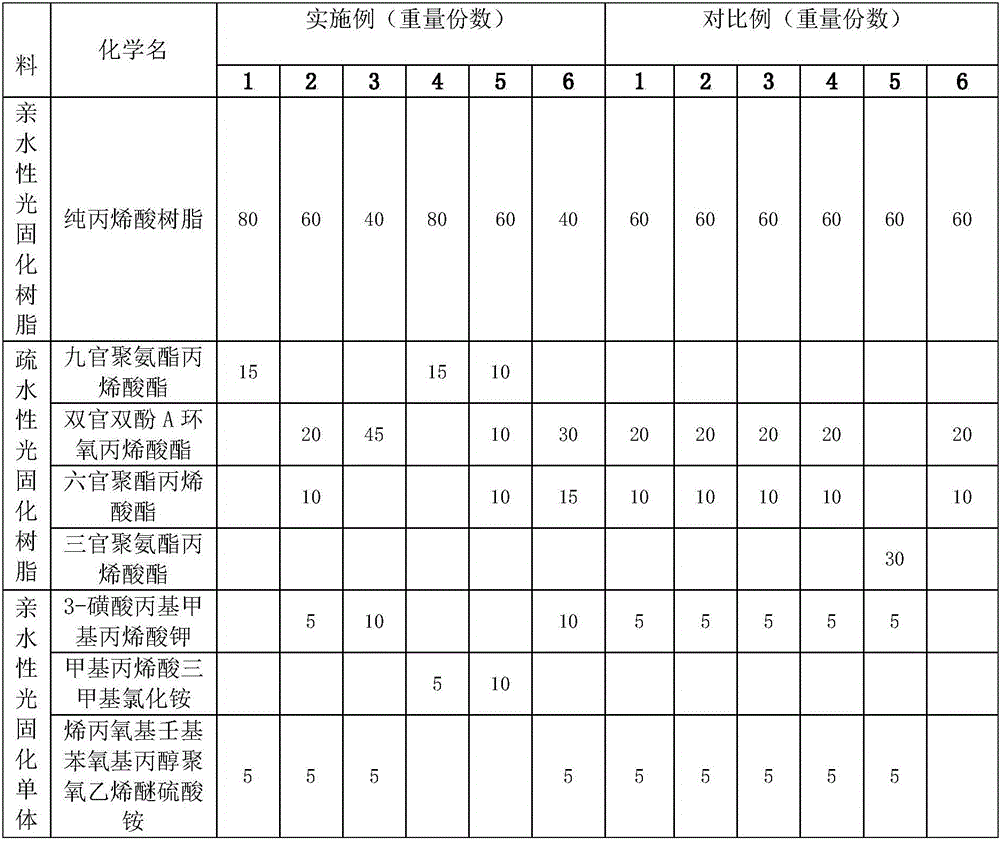

[0046] This embodiment provides a UV-curable anti-fog coating composition, and the components and parts by weight of the composition are shown in Table 1.

[0047] The synthetic method of pure acrylic resin described in the present embodiment is as follows:

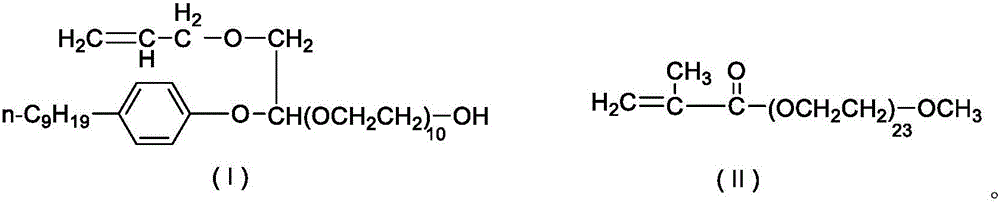

[0048] In a 250 ml four-necked bottle equipped with a mechanical stirrer, a thermometer, and a nitrogen gas introduction device, add ethylene glycol monomethyl ether (20 grams), first add 20% monomer, initiator AIBN (0.21 grams) and ethylene glycol The mixture of monomethyl ether (40 grams) was raised to 80-85 degrees, and reacted for 0.5 hours. Then dropwise add the mixture of remaining monomer, initiator and ethylene glycol monomethyl ether within 2 hours, after the dropwise addition, continue to react for 3 hours. The monomers include: monomer I (9.7 g, 12.5 mmol), monomer II (8.9 g, 8.3 mmol), HBA (1.2 g, 8.3 mmmol), AA (0.9 g, 12.5 mmol).

[0049] Add GMA (9.3 grams, 12.5mmol), benzyltrimethylammonium chloride cata...

Embodiment 2

[0051] This embodiment provides a UV-curable anti-fog coating composition, and the components and parts by weight of the composition are shown in Table 1.

[0052] The synthetic method of pure acrylic resin described in the present embodiment is as follows:

[0053] In a 250 ml four-necked bottle equipped with a mechanical stirrer, a thermometer, and a nitrogen gas introduction device, add ethylene glycol monomethyl ether (20 grams), first add 20% monomer, initiator AIBN (0.24 grams) and ethylene glycol The mixture of monomethyl ether (40 grams) was raised to 80-85 degrees, and reacted for 0.5 hours. Then dropwise add the mixture of remaining monomer, initiator and ethylene glycol monomethyl ether within 2 hours, after the dropwise addition, continue to react for 3 hours. The monomers include: monomer I (12.9 g, 16.6 mmol), monomer II (8.9 g, 8.3 mmol), HBA (1.2 g, 8.3 mmmol), AA (0.6 g, 8.3 mmol).

[0054] Add GMA (6.2 grams, 16.6mmol), benzyltrimethylammonium chloride cata...

Embodiment 3

[0056] This embodiment provides a UV-curable anti-fog coating composition, and the components and parts by weight of the composition are shown in Table 1.

[0057] The synthetic method of pure acrylic resin described in the present embodiment is as follows:

[0058] In the 250 milliliter four-necked bottle that is equipped with mechanical stirring, thermometer, nitrogen introduction device, add ethylene glycol monomethyl ether (25 grams), add 20% monomer, initiator AIBN (0.26 grams) and ethylene glycol earlier The mixture of monomethyl ether (40 grams) was raised to 80-85 degrees, and reacted for 0.5 hours. Then dropwise add the mixture of remaining monomer, initiator and ethylene glycol monomethyl ether within 2 hours, after the dropwise addition, continue to react for 3 hours. The monomers are: monomer I (6.4 g, 8.3 mmol), II (17.8 g, 16.6 mmol), HBA (1.2 g, 8.3 mmmol), AA (0.6 g, 8.3 mmol).

[0059] Add GMA (6.1 grams, 8.3mmol), benzyltrimethylammonium chloride catalyst (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com