Infrared-radiation heat-dissipation water-based wear-resistant non-stick paint and preparation method thereof

An infrared radiation, non-stick coating technology, used in polyamide coatings, multi-color effect coatings, coatings, etc., can solve problems such as coating damage and heat accumulation, and achieve high infrared emissivity, low VOC emissions, and stable effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a method for preparing the above-mentioned infrared radiation heat dissipation water-based wear-resistant non-stick coating, comprising the following steps:

[0034] First, the high-temperature-resistant pigments, wear-resistant fillers, and infrared radiation materials in the composition are ground in water and organic solvents until the particle size of each material is ≤10um, then the remaining components are added, and the target product is obtained by stirring evenly.

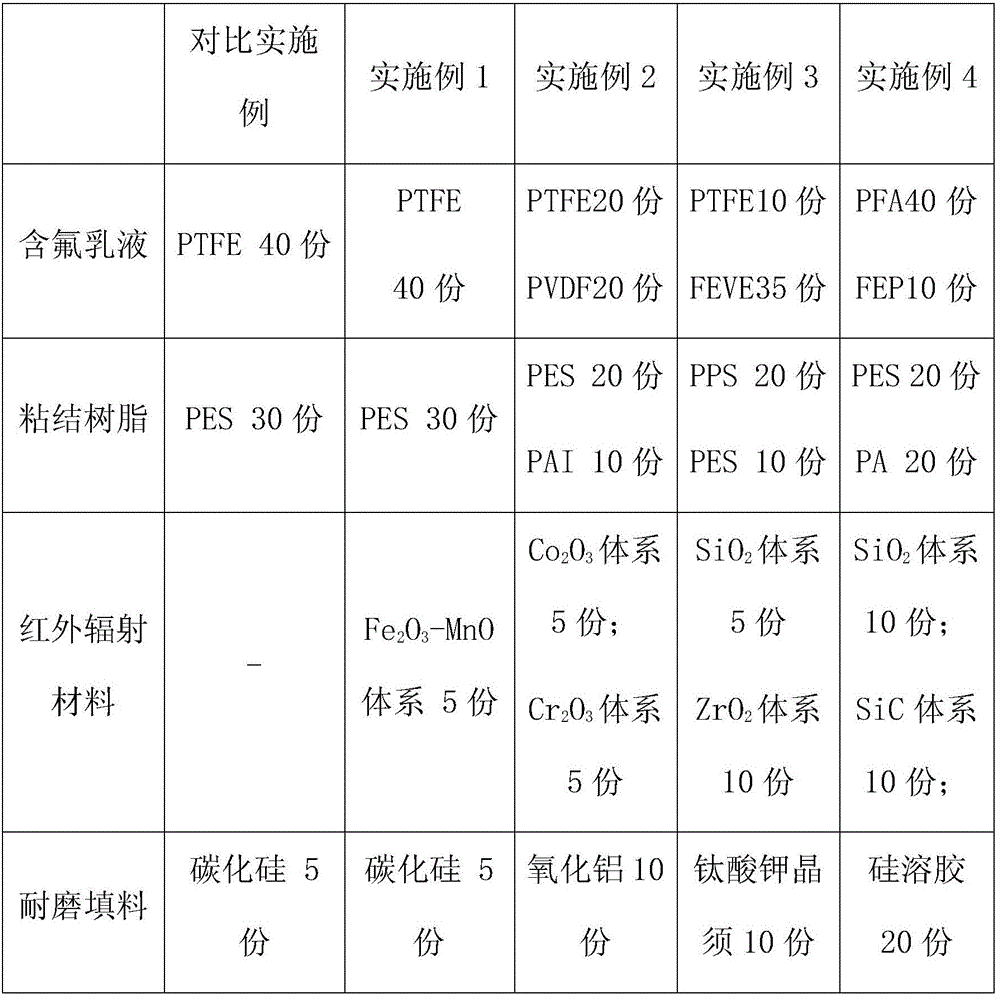

[0035] Embodiment 1-4 and comparative example

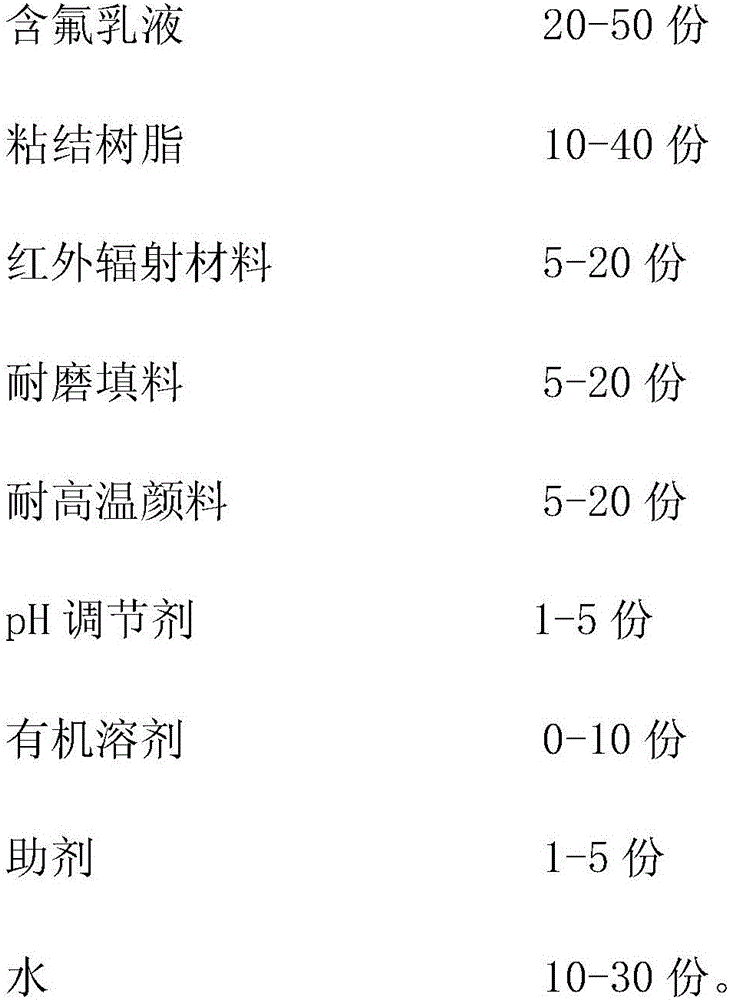

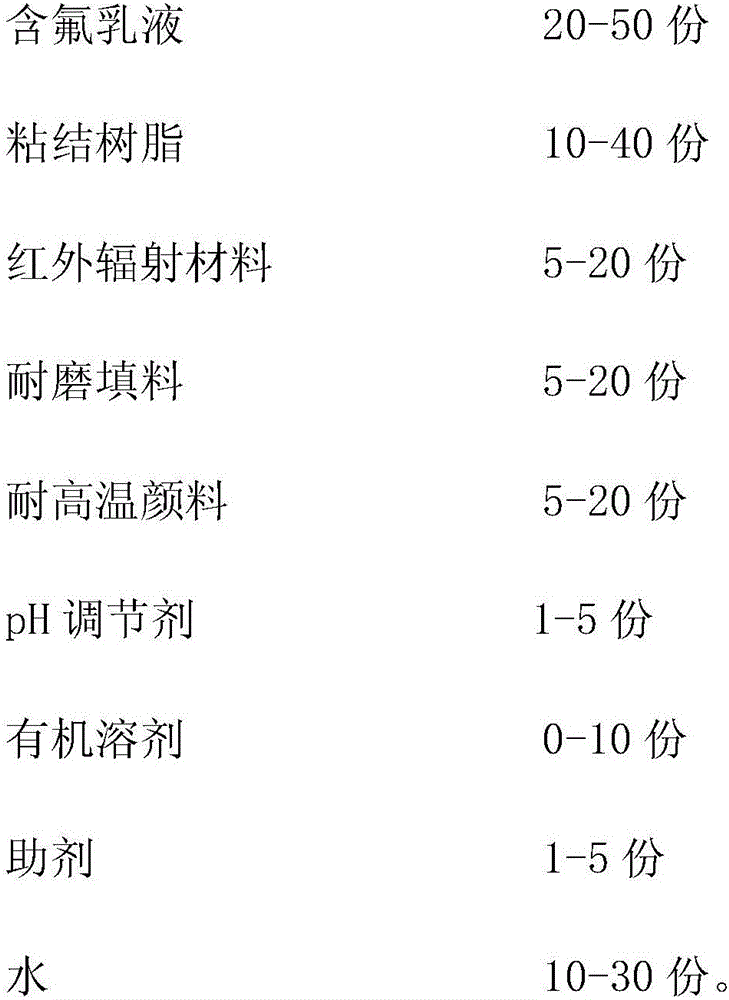

[0036] According to the formula of the non-stick coating shown in following table 1, make non-stick coating according to preparation method of the present invention:

[0037] The formula of table 1 embodiment 1-4 and comparative example non-stick coating

[0038]

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com