Heat-resistant natural rubber and preparation method thereof

A natural rubber and heat-resistant technology, which is applied in the field of resistant modified natural rubber and its preparation, can solve the problems of low heat aging performance, achieve good heat resistance, improve heat resistance, and improve thermal environment performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

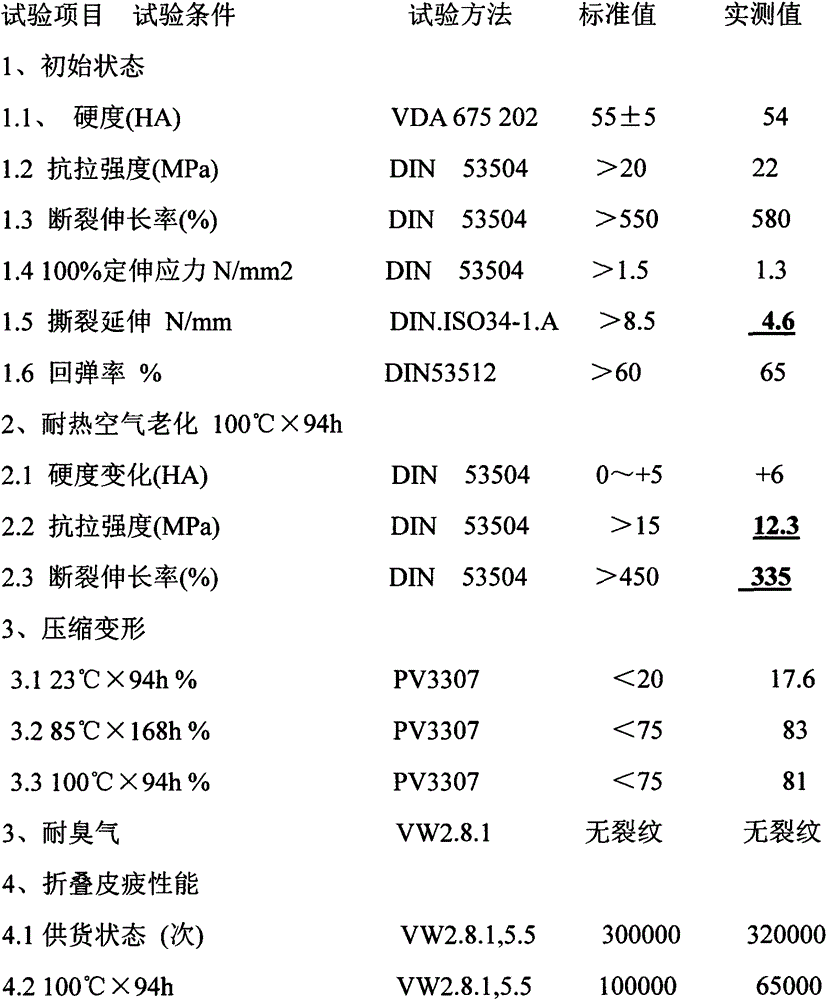

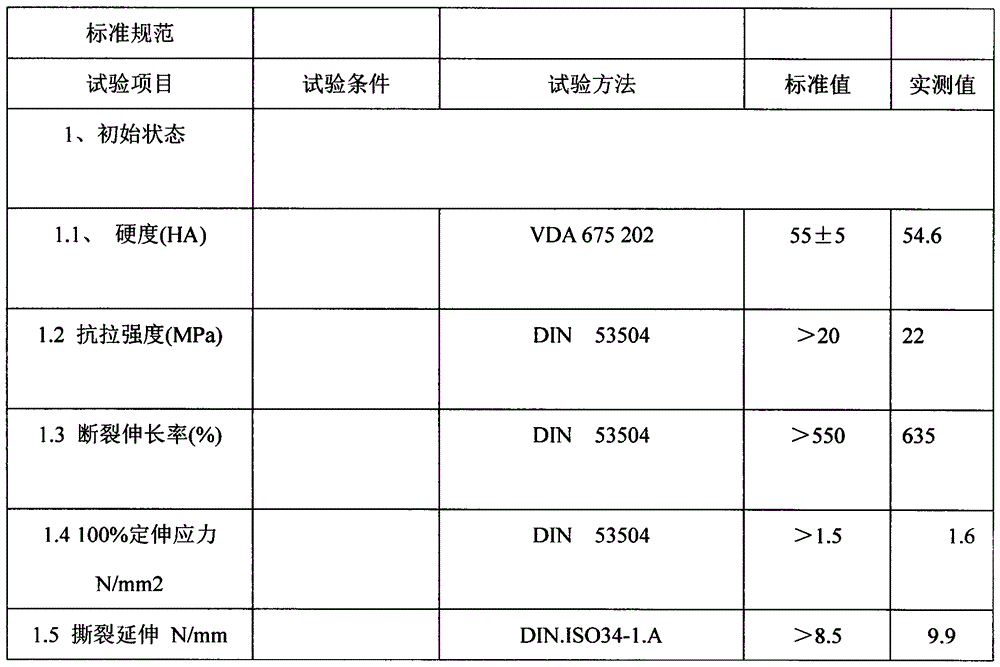

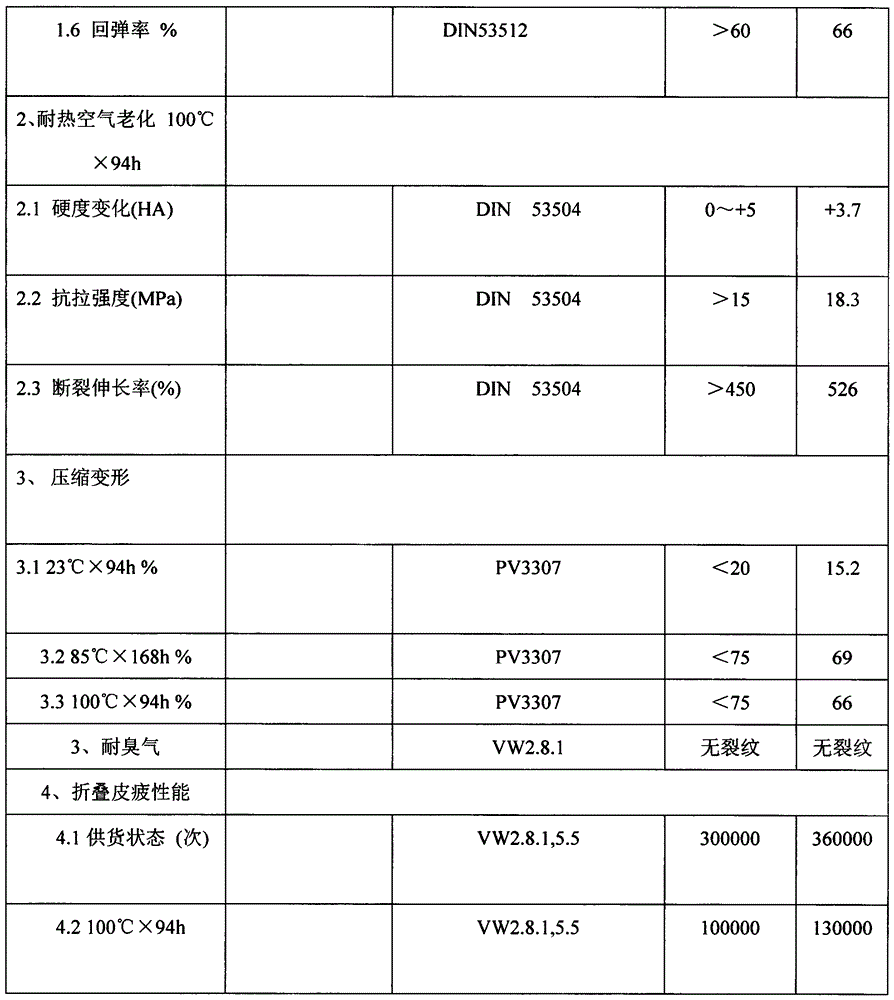

[0022] Product name: heat-resistant modified natural rubber material used for automobile chassis vibration damping products;

[0023] formula:

[0024] Formula unit is weight percent;

[0025] Rubber raw materials; natural rubber, 51%

[0026] Rubber raw material: EPDM rubber, 13.5%;

[0027] Reinforcing agent: quick-pressed carbon black, 17.5%;

[0028] Reinforcing agent; silica, 7.5%

[0029] Plasticizer: paraffin oil, 4.2%;

[0030] Active agent: zinc oxide 3.2%;

[0031] Vulcanizing agent: sulfur, 0.9%;

[0032] Processing aids: Accelerator, 2.2%;

[0033] preparation:

[0034] Preparation conditions, equipment

[0035] Ambient pressure: one atmosphere;

[0036] Ambient temperature: room temperature;

[0037] Preparation equipment: XK-660 open rubber mixer, FARREL K6 internal mixer;

[0038] Preparation process: mixing;

[0039] Step 1. Preheat the internal mixer with water, control the temperature of the internal mixer working room to <50°C, and the speed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com