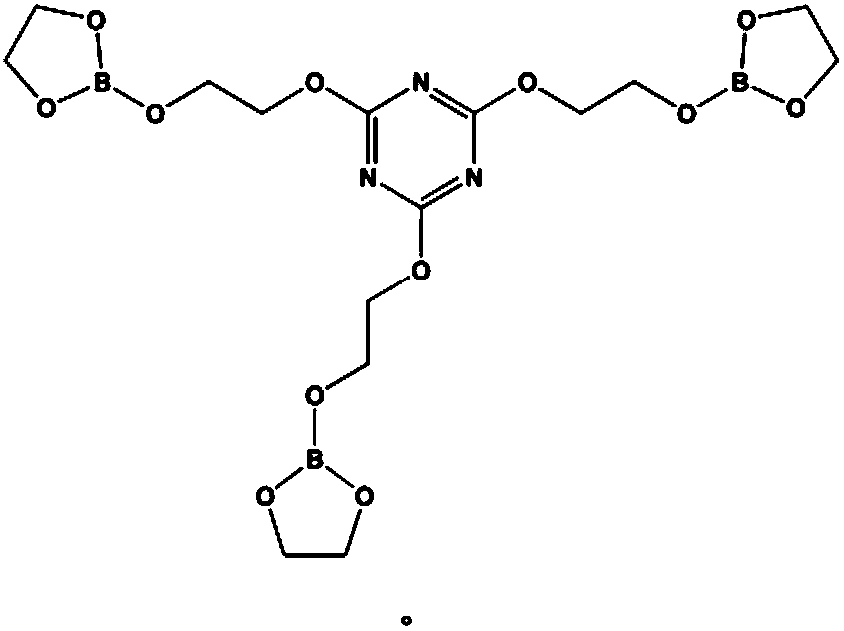

Intumescent flame retardant based on star triazine derivatives and preparation method thereof

A technology of intumescent flame retardants and triazine derivatives, which is applied in the field of intumescent flame retardants and their preparation, can solve the problems of toxicity and weak flame retardant performance, prevent dripping, prevent burning, and solve the problems of high toxicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of an intumescent flame retardant based on a star triazine derivative, comprising the steps of:

[0031] Step 1: Add 13.5ml of ethylene glycol and 140ml of toluene into a three-necked flask, stir and gradually raise the temperature to 48°C, add 7.35g of boric acid, continue to heat up to 73°C, and stir for 50 minutes until the boric acid is completely dissolved; No more increase, continue to react for 1h;

[0032] Step 2: Distill the reaction solution in the first step to remove toluene under reduced pressure, and dry it in vacuum at 70° C. to obtain an intermediate product of a colorless transparent viscous liquid; dissolve 12.29 g of the intermediate product in 60 ml of tetrahydrofuran solution;

[0033] The third step: under the protection of nitrogen, weigh 5.67g of cyanuric chloride and dissolve it in 40ml of tetrahydrofuran solution, then add 4.11g of sodium hydroxide, and at 26°C, add half of the volume of the tetrahydrofuran solution in whic...

Embodiment 2

[0039] A preparation method of an intumescent flame retardant based on a star triazine derivative, comprising the steps of:

[0040] Step 1: Add 27ml of ethylene glycol and 270ml of toluene into the three-necked flask, stir and gradually raise the temperature to 59°C, add 14.76g of boric acid, continue to raise the temperature to 81°C, and stir for 55 minutes until the boric acid is completely dissolved; Increase again, continue to react for 2h;

[0041] Step 2: Distill the reaction solution of the first step to remove toluene under reduced pressure, and dry it in vacuum at 70° C. to obtain an intermediate product of a colorless transparent viscous liquid; dissolve 25.57 g of the intermediate product in 120 ml of tetrahydrofuran solution;

[0042] The third step: under the protection of nitrogen, weigh 11.32g of cyanuric chloride and dissolve it in 80ml of tetrahydrofuran solution, then add 8.56g of sodium hydroxide, at 20°C, add 40% of the volume of the intermediate product tet...

Embodiment 3

[0045] A preparation method of an intumescent flame retardant based on a star triazine derivative, comprising the steps of:

[0046] Step 1: Add 41ml of ethylene glycol and 420ml of toluene into the three-necked flask, stir and gradually raise the temperature to 58°C, add 22.14g of boric acid, continue to raise the temperature to 73°C, and stir for 50 minutes until the boric acid is completely dissolved; Increase again, continue to react for 2h;

[0047] Step 2: Distill the reaction liquid of the first step to remove toluene under reduced pressure, and dry it in vacuum at 70° C. to obtain an intermediate product of a colorless transparent viscous liquid; dissolve 36.89 g of the intermediate product in 180 ml of tetrahydrofuran solution;

[0048] The third step: under the protection of nitrogen, take by weighing 17.32g cyanuric chloride and dissolve in 120ml tetrahydrofuran solution, then add 12.43g sodium hydroxide, at 24 ℃, add 60% of the volume of the tetrahydrofuran solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat release rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com