Water treatment filler based on modified biomass ash and preparing method thereof

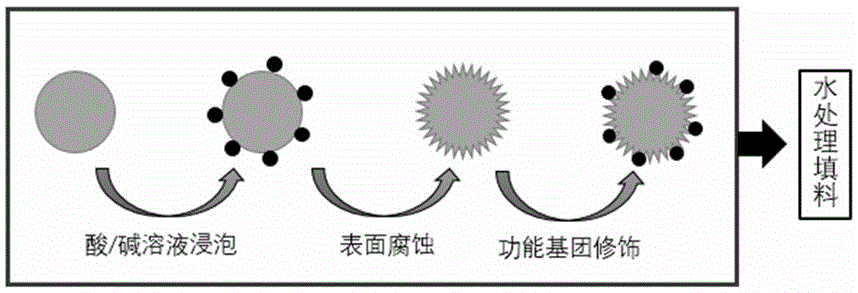

A biomass ash and water treatment technology, applied in the field of water treatment, to achieve the effect of increased specific surface area, increased surface functional groups, and good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A mixed solution was prepared using acetic acid and sodium alginate. The volume of water was 1 L, the volume of acetic acid was 15 mL, and the concentration of sodium alginate was 0.08 mol / L. Table 1 shows the specific specifications of biomass ash; 0.6 kg of sieved 4#, 5# and 6# biomass ash was added to the mixed solution, stirred and mixed uniformly, soaked and rinsed at 40℃, rinsed three times, after each rinse, according to the health The ratio of the material ash to the mixed liquid requires replacement of the mixed liquid; soaking for ten minutes is required before the second and third rinsing; the water treatment filler based on the modified biomass ash is obtained by drying. The modification principle is as follows figure 1 Shown. The specific surface area of 6 batches of water treatment filler modified by this method was measured, and the specific surface area was 3.71~5.83 m 2 / g, the average specific surface area is 4.47 m 2 / g, 20%~75% higher than before mod...

Embodiment 2

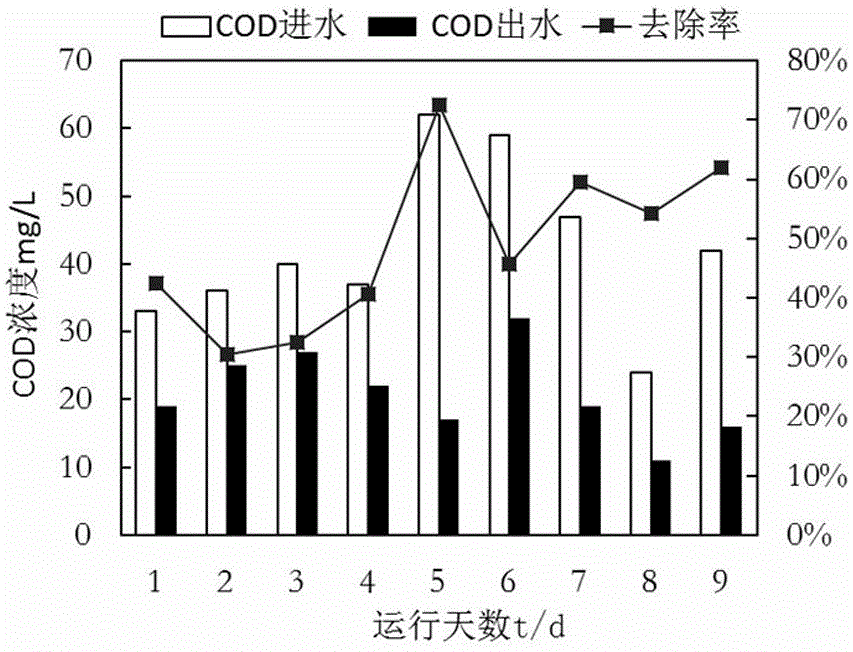

[0030] Acetic acid and sodium alginate are used to prepare a mixed solution, where the volume of water is 1 L, the volume of acetic acid is 20 mL, and the concentration of sodium alginate is 0.1 mol / L; 4# and 5# after sieving 0.6 kg respectively He 6# (Table 1) biomass ash residue was added to the mixed solution, stirred and mixed uniformly, soaked and rinsed at 35℃, rinsed three times, after each rinse, according to the biomass ash residue and the mixed solution The ratio requires replacement of the mixed liquid; soaking for ten minutes before the second and third rinsing; drying to obtain a water treatment filler based on modified biomass ash. The specific surface area of 6 batches of water treatment filler modified by this method was measured, and the specific surface area was 3.65~5.72 m 2 / g, the average specific surface area is 4.31 m 2 / g, 20%~75% higher than before modification. Taking the raw water of the inferior Class V river as the treatment object, the experiment...

Embodiment 3

[0032] Use acetic acid and sucrose to prepare a mixed solution, where the volume of water is 1 L, the volume of acetic acid is 15 mL, and the concentration of sucrose is 0.08mol / L; 0.6 kg of 4#, 5# and 6# are sieved separately (Table 1) Add biomass ash to the mixed solution, stir and mix evenly, soak and rinse at 40℃, rinse for three times, after each rinse, change and mix according to the ratio of biomass ash to mixed solution Soak for ten minutes before the second and third rinsing; dry to obtain water treatment filler based on modified biomass ash. The specific surface area of 6 batches of water treatment filler modified by this method was measured, and the specific surface area was 3.01~4.28 m 2 / g, the average specific surface area is 3.56 m 2 / g, 20%~55% higher than before modification. Taking the raw water of the inferior Class V river as the treatment object, the experiment was conducted through the combined process of simultaneous nitrogen and phosphorus removal and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com