Independent suspension type front drive rear axle assembly

An independent suspension and front drive technology, applied in the direction of brakes, brake components, axles, etc., can solve the problems affecting the overall layout, long drive shaft, increase the weight of the car, etc., to reduce the weight of the rear axle and the weight of the whole vehicle, system system Improved, stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Further illustrate the present invention below in conjunction with embodiment and accompanying drawing.

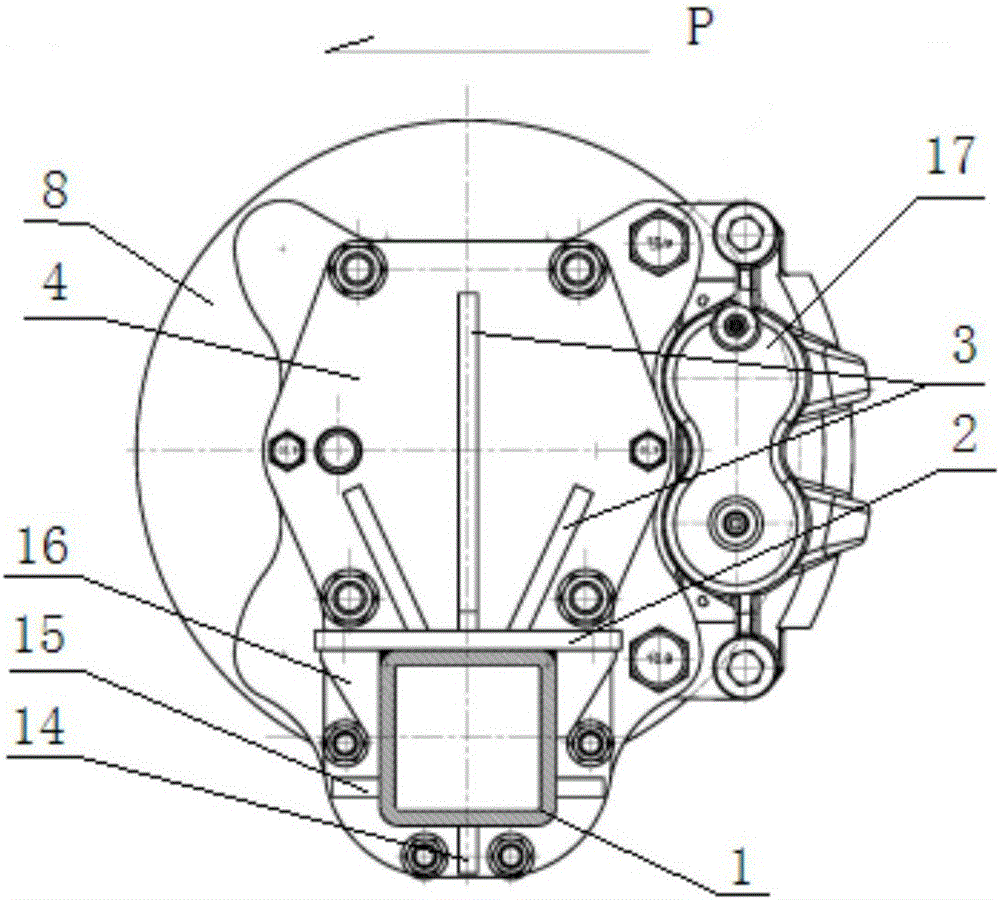

[0027] Such as figure 1 , 2 In the shown embodiment, the two ends of the rear axle beam 1 are provided with symmetrical flanges 4 that are fitted and fixed by welding, and the upper surfaces of the two ends of the rear axle beam 1 are provided with flanges that are welded and fixed to the rear side of the rear axle beam and the flange. The mounting seat plate 2 of the leaf spring suspension (not shown) is provided with a welded and fixed reinforcing rib plate I3 between the mounting seat plate 2 and the rear side of the flange plate 4 .

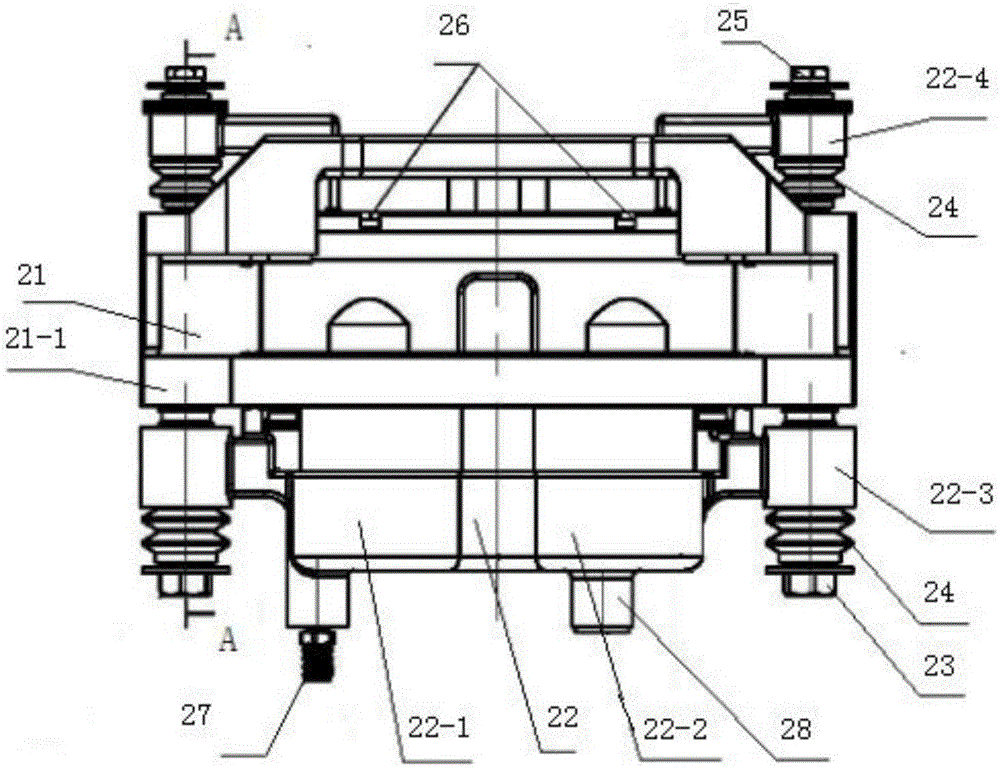

[0028] The top of each flange 4 is symmetrically provided with a rear axle head 6 fastened by symmetrically arranged bolts 5, and the center distance between the center of the rear axle head 6 and the rear axle beam 1 is 130-160mm, and the center distance of the embodiment is 150mm.

[0029] The rear axle head 6 supports the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com