Preparation process for thin ferrite sheet

A ferrite sheet and preparation process technology, which is applied to manufacturing tools, ceramic molding machines, etc., can solve the problems of low yield of thin ferrite sheets, easily deformed reject rate, large amount of raw materials, etc. Not easy to deform, small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Press 80g ferrite raw material to obtain ferrite slab, the thickness of the ferrite slab is 10mm, and the diameter of the ferrite slab is 50mm; the ferrite raw material is Fe 2 o 3 , ZnO and Mn 3 o 4 , Fe 2 o 3 Accounting for 70wt% of the ferrite raw material, ZnO accounting for 8wt% of the ferrite raw material, Mn 3 o 4 Accounting for 22wt% of the ferrite raw material;

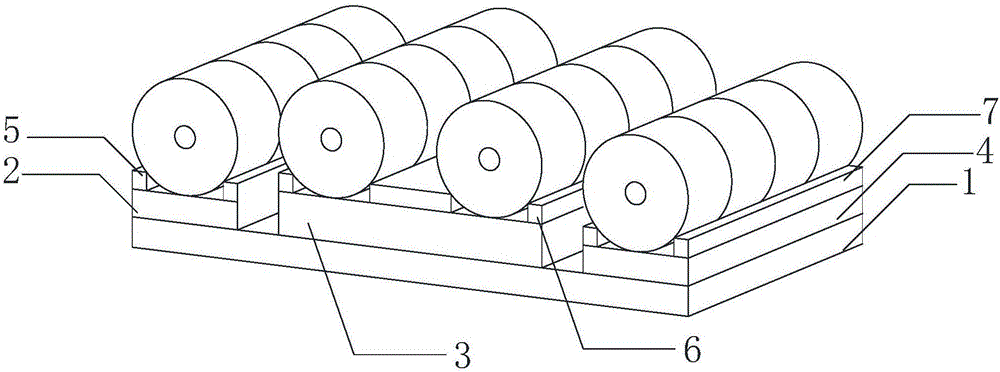

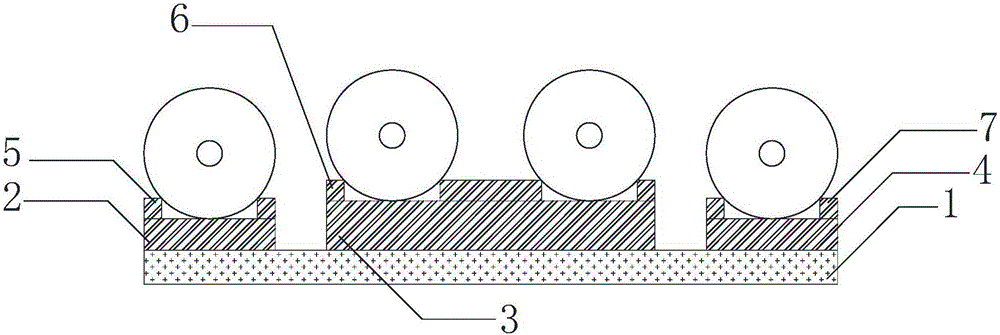

[0034] 2) Sintering, slicing and cleaning the ferrite slab obtained in step 1), and slicing it with a circular ferrite sheet cutting bracket, as figure 1 with figure 2 As shown, the annular ferrite sheet cutting bracket at least includes an iron plate 1, a left glass plate 2, a middle glass plate 3 and a right glass plate 4, and the left glass plate 2, the middle glass plate 3 and The right glass plate 4 is arranged on the iron plate 1, and a first glass strip 5 is respectively arranged on both sides of the left glass plate 2, and the distance between the first glass strips 5 is not greater...

Embodiment 2

[0037] 1) 780g ferrite raw material is pressed to obtain a ferrite slab, the thickness of the ferrite slab is 20mm, and the diameter of the ferrite slab is 100mm; the ferrite raw material is Fe 2 o 3 , ZnO and Mn 3 o 4 , Fe 2 o 3 Accounting for 73wt% of ferrite raw materials, ZnO accounts for 7wt% of ferrite raw materials, Mn 3 o 4 Accounting for 20wt% of the ferrite raw material; the ferrite raw material can also include Co 2 o 3 , NiO and CaO, etc., with Fe 2 o 3 , ZnO and Mn 3 o 4 Based on the total weight of Co 2 o 3 : 0.02wt%, NiO: 0.03wt%, CaO: 0.04wt%;

[0038] 2) Sintering, slicing and cleaning the ferrite slab obtained in step 1), and slicing it with a circular ferrite sheet cutting bracket, as figure 1 with figure 2 As shown, the annular ferrite sheet cutting bracket at least includes an iron plate 1, a left glass plate 2, a middle glass plate 3 and a right glass plate 4, and the left glass plate 2, the middle glass plate 3 and The right glass plate ...

Embodiment 3

[0041]1) 6g of ferrite raw material is pressed to obtain a ferrite slab, the thickness of the ferrite slab is 15mm, and the diameter of the ferrite slab is 10mm; the ferrite raw material is Fe 2 o 3 , ZnO and Mn 3 o 4 , Fe 2 o 3 Accounting for 72wt% of the ferrite raw material, ZnO accounts for 9wt% of the ferrite raw material, Mn 3 o 4 It accounts for 19wt% of the ferrite raw material; the ferrite raw material can also include Co 2 o 3 , NiO and CaO, etc., with Fe 2 o 3 , ZnO and Mn 3 o 4 Based on the total weight of Co 2 o 3 : 0.04wt%, NiO: 0.01wt%, CaO: 0.02wt%;

[0042] 2) Sintering, slicing and cleaning the ferrite slab obtained in step 1), and slicing it with a circular ferrite sheet cutting bracket, as figure 1 with figure 2 As shown, the annular ferrite sheet cutting bracket at least includes an iron plate 1, a left glass plate 2, a middle glass plate 3 and a right glass plate 4, and the left glass plate 2, the middle glass plate 3 and The right glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com