Hot isostatic pressure diffusion connection preparation method of heterogeneous composite component

A technology of hot isostatic pressure diffusion and composite components, which is applied in the direction of pump components, mechanical equipment, variable capacity pump components, etc., can solve the problem that the bonding strength cannot meet the use requirements, the expansion coefficient is very different, and the thermal stress bonding interface cracks and leaks and other issues, to achieve stable and reliable product quality, simplify the production process, and enhance the effect of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

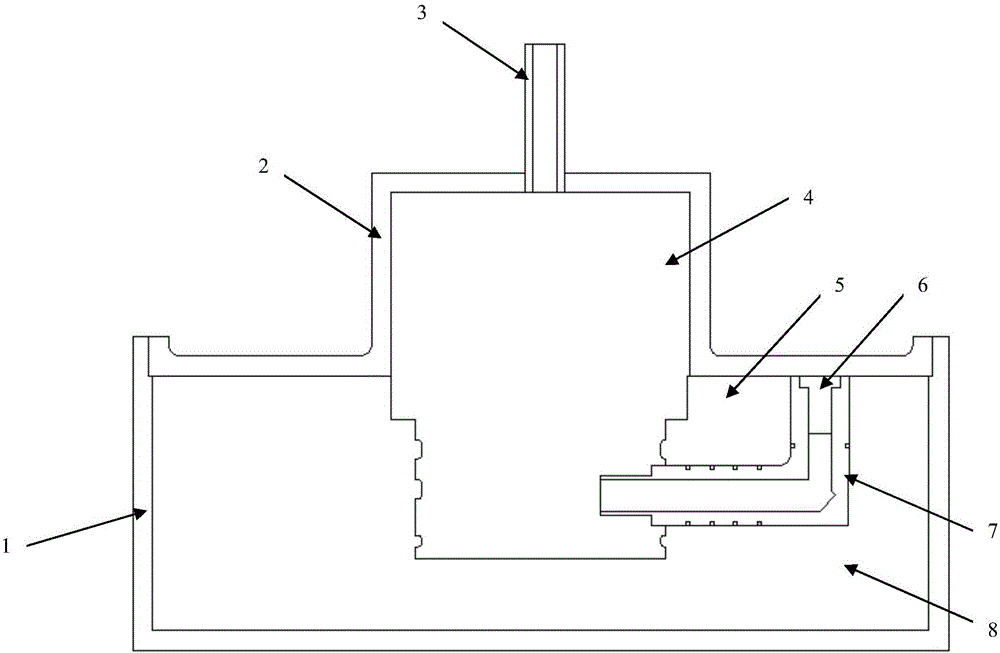

[0038] The method for preparing the hot isostatic pressing diffusion connection of heterogeneous composite members of the present invention specifically includes the following steps:

[0039] Step (1), according to the shape and size of the composite component to be prepared, design and process the basic components that make up the composite component. The basic components include the shapes of the base blank 8, the insert 5, the cylinder liner blank 4 and the joint blank 7, and the base The blank 8, the insert 5, the cylinder liner blank 4 and the joint blank 7 are processed from at least two different metal materials, for example, the base blank 8 and the insert 5 are made of aluminum alloy, the cylinder liner blank 4 is made of ductile iron, and the joint blank 7 is made of stainless steel, preferably the base blank 8 and insert 5 are made of 5A06 aluminum alloy, the cylinder liner blank 4 is made of QT550 or QT550A ductile iron, and the joint blank 7 is made of 0Cr18Ni9 or ...

Embodiment 1

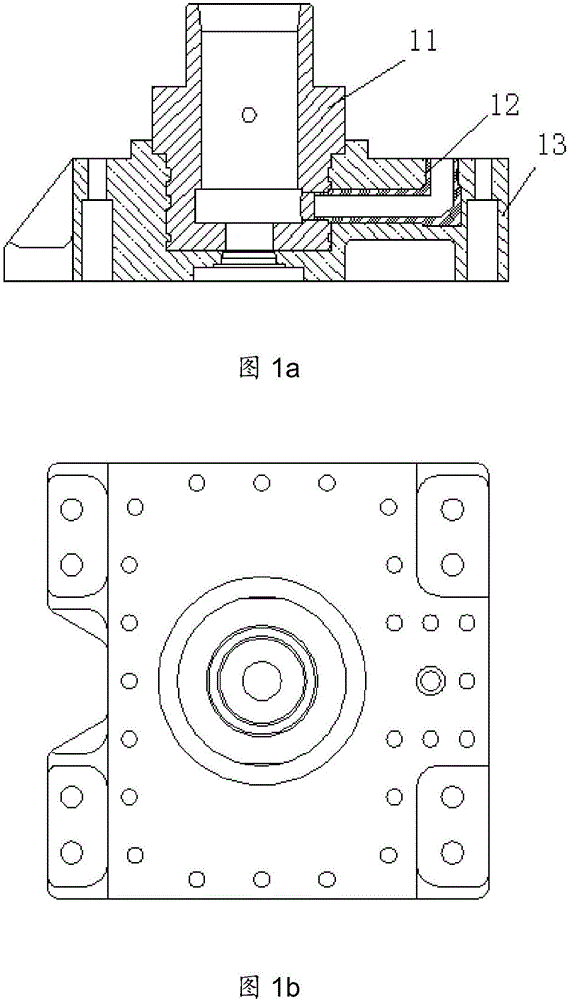

[0048] Take the manufacture of an aluminum-iron-steel composite member with a size of 180×180×100mm as an example, such as figure 1 Shown is a schematic diagram of the aluminum-iron-steel composite member in the embodiment of the present invention.

[0049] (a) Preparation of various components of the basic components and package components

[0050] Based on composite components (such as figure 1 ) Product shape and size, considering the subsequent machining allowance, processing the base blank 8, insert block 5, cylinder liner blank 4, joint blank 7 and other component blanks, hot isostatic pressing package components and pads 6. Among them, the matrix blank 8 is a rectangular structure, and the middle part reserves space for placing inserts 5, cylinder liner blanks 4, joint blanks 7 and other components. The insert 5 is a strip structure, and the cylinder liner blank 4 is a cylindrical structure, with joints reserved on one side The space for placing the blank 7, the joint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com