Processing method for front half body combination of riding type motorcycle frame

A riding motorcycle and combined processing technology, applied in metal processing equipment, manufacturing tools, auxiliary devices, etc., can solve the problems of increasing processing difficulty and complexity, and achieve ideal positioning effect, reduce processing difficulty and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described in detail below in conjunction with the accompanying drawings. Wherein, the descriptive terms such as up, down, left, right, etc. are used for the description, with the purpose of helping readers to understand, but not intended to limit.

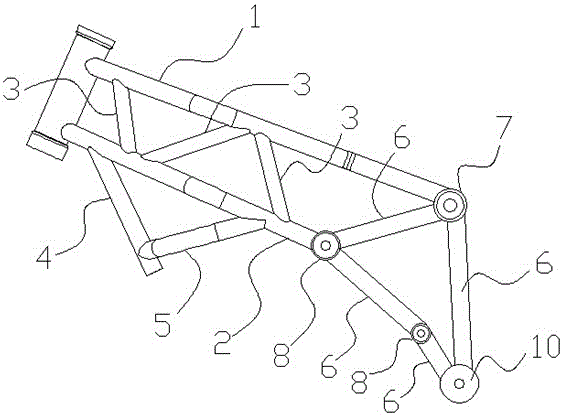

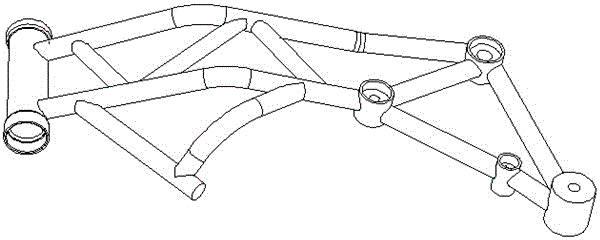

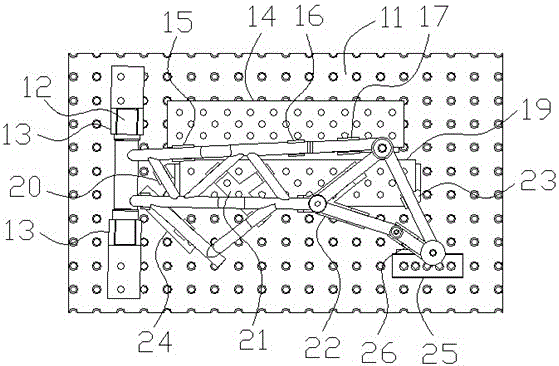

[0058] A combined processing method for the front half body of a ride-on motorcycle frame, comprising the following steps: firstly separately complete the front upper tube 1, the front lower tube 2, the oblique reinforcement tube 3, the front slant brace tube 4, the front slant brace reinforcement tube 5, Processing of shaft sleeve connection pipe 6, cross bar positioning shaft sleeve 7, engine installation shaft sleeve 8, suspension shaft sleeve 9 and flat fork installation shaft sleeve 10; Pipe 3, front diagonal brace pipe 4, front diagonal brace reinforcement pipe 5, bushing connecting pipe 6, crossbar positioning bushing 7, engine mounting bushing 8, suspension bushing 9 and flat for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com