Safe casting die for brake wheel

A technology for casting molds and braking wheels, which is used in manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of difficult mold release, complex structure, physical harm to workers, etc. The effect of security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

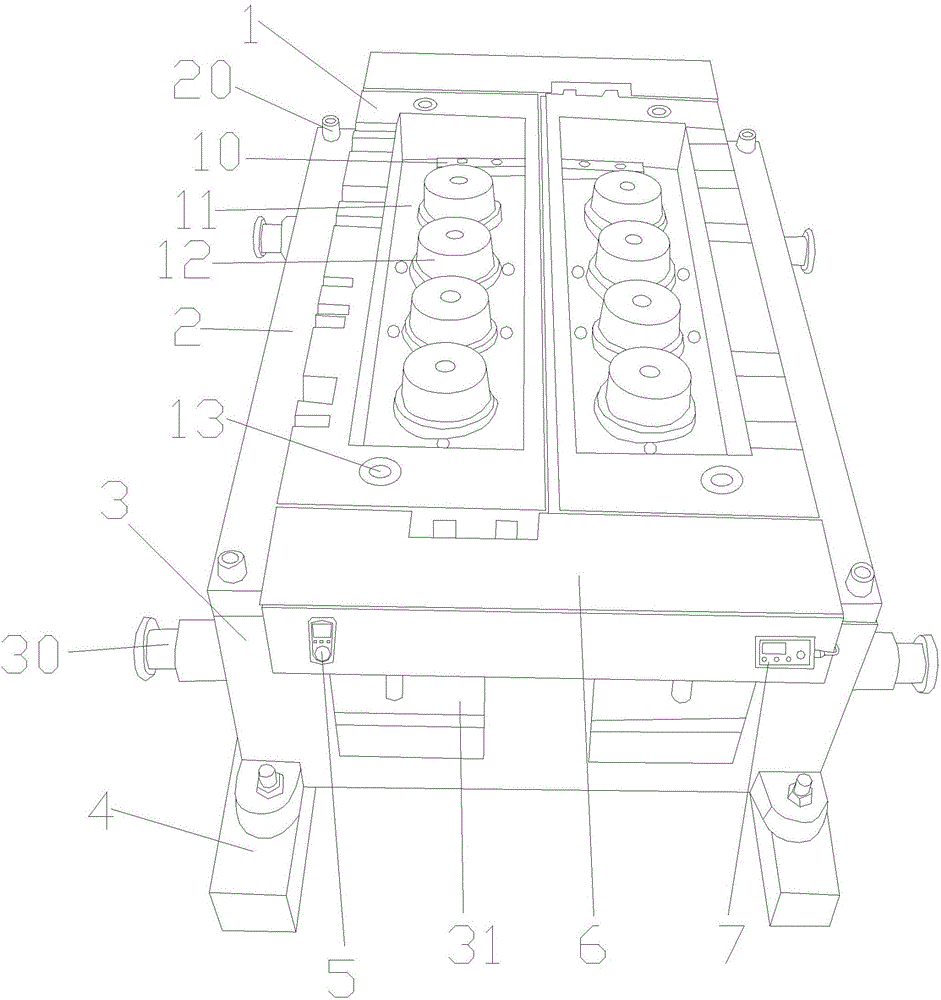

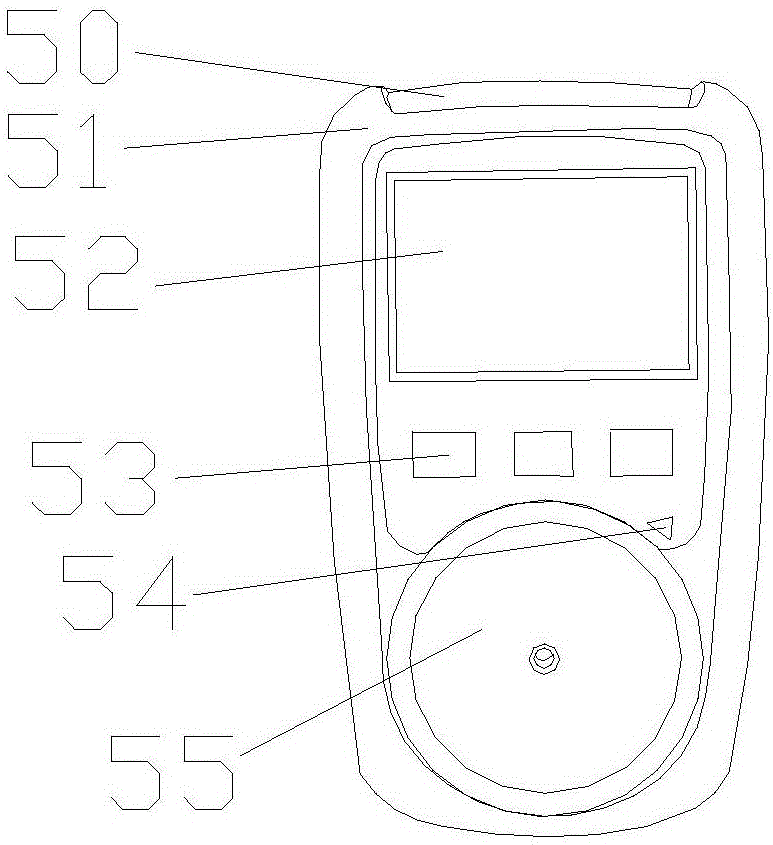

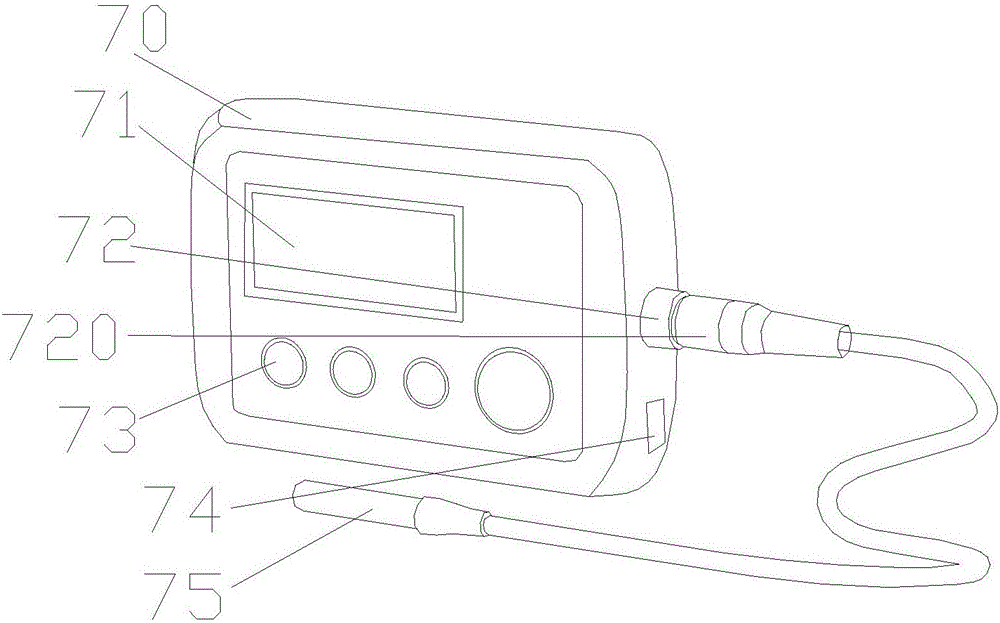

[0014] See Figure 1-3 , The present invention provides a safety brake wheel casting mold, which structure includes a casting module 1, a machine table 2, a machine body 3, a machine base 4, a gas alarm device 5, a fixed block 6, a temperature detector 7, and the casting module 1 is set on the machine table 2, the machine table 2 is fixedly connected to the machine body 3, the machine body 3 is fixedly connected to the machine base 4, the gas alarm device 5 is provided on the fixed block 6, the fixed block 6 and the casting The module 1 is connected, the temperature detector 7 is arranged on the fixed block 6, the casting module 1 includes a lifting module 10, a casting mold groove 11, a model block 12, and a casting inlet 13, the lifting module 10 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com