Hemming and inspecting production line for suspension base

A production line and suspension technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problem of limited hemming processing speed, and achieve the effect of improving efficiency, avoiding upside down and preventing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

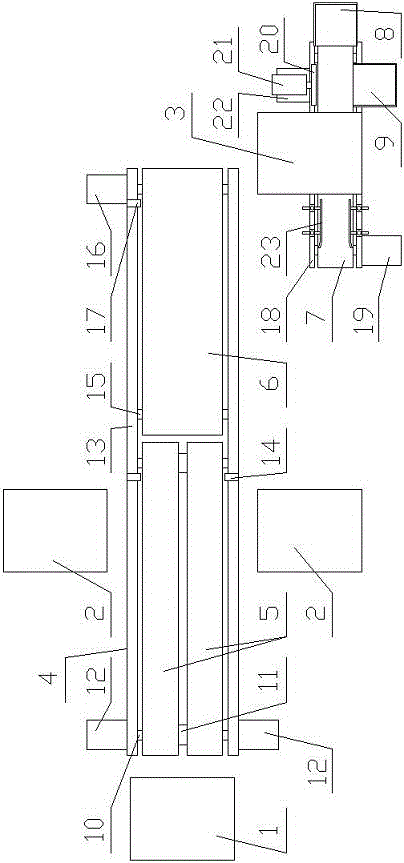

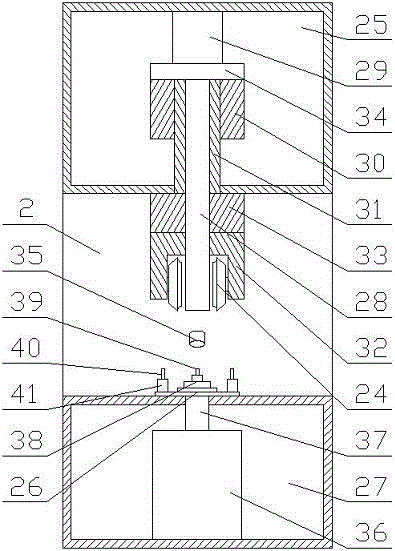

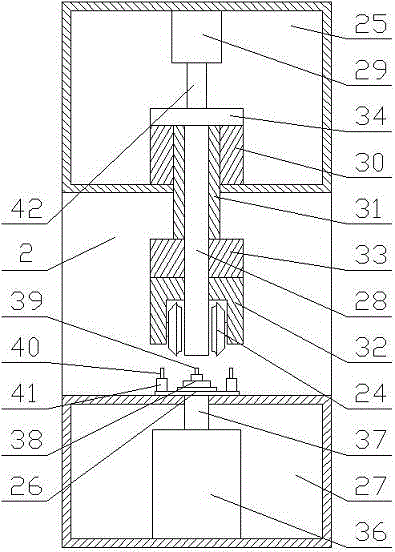

[0038] to combine Figure 1~Figure 4As shown, the present invention includes a feeding device 1, a crimping device 2 and a testing device in turn, and the feeding device 1, the crimping device 2 and the testing device are transmitted through a transmission device; the transmission device includes a transmission rack A4 The end of the transmission frame A4 close to the feeding device 1 is movably connected to the conveyor belt A5 through the rotating shaft A10, and the end of the transmission frame A4 away from the feeding device 1 is movably connected to the conveyor belt B6 through the rotating shaft B15, and the rotating shaft A10 is connected by the motor A12 The driving force is provided, and the rotating shaft B15 provides the driving force through the motor B16, and the motor A12 and the motor B16 are respectively fixed on the transmission frame A4; The position between B6; the inspection device is located at the end position of the conveyor belt B6; the crimping device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com