Primary connection crimping device of high-voltage current transformer

A crimping device, high-voltage current technology, applied in circuit/collector parts, inductor/transformer/magnet manufacturing, circuits, etc., can solve the problem of no high-voltage current transformer for one-time use, improve convenience, avoid processing Accuracy error, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

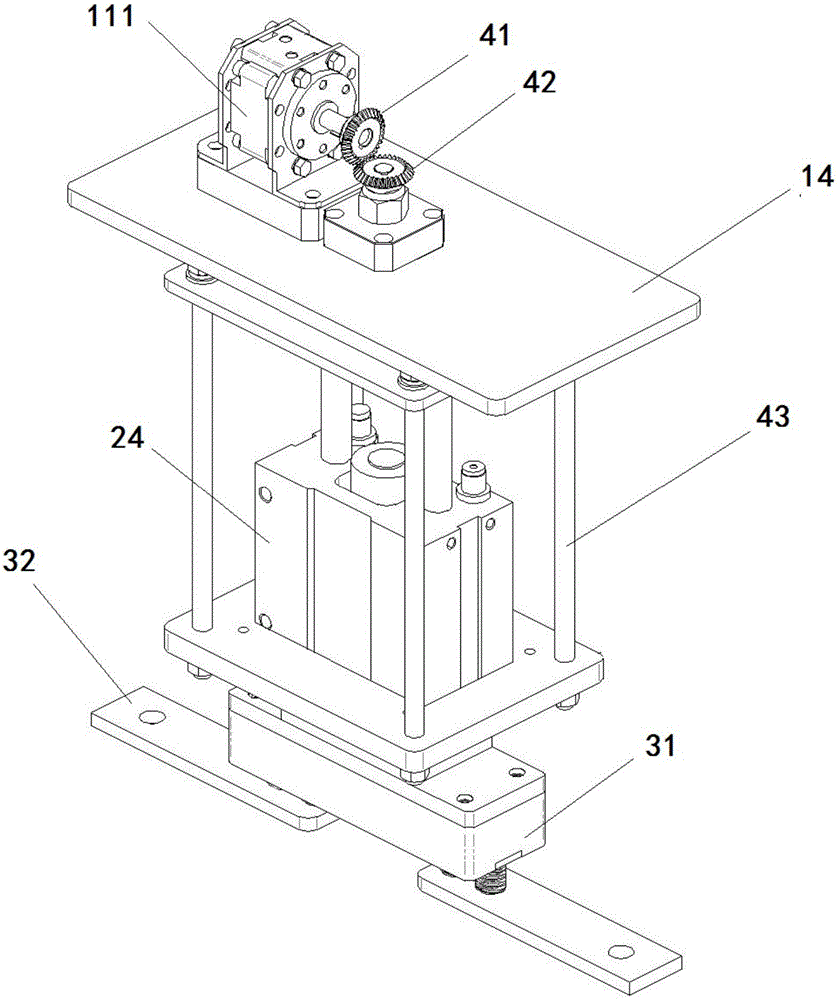

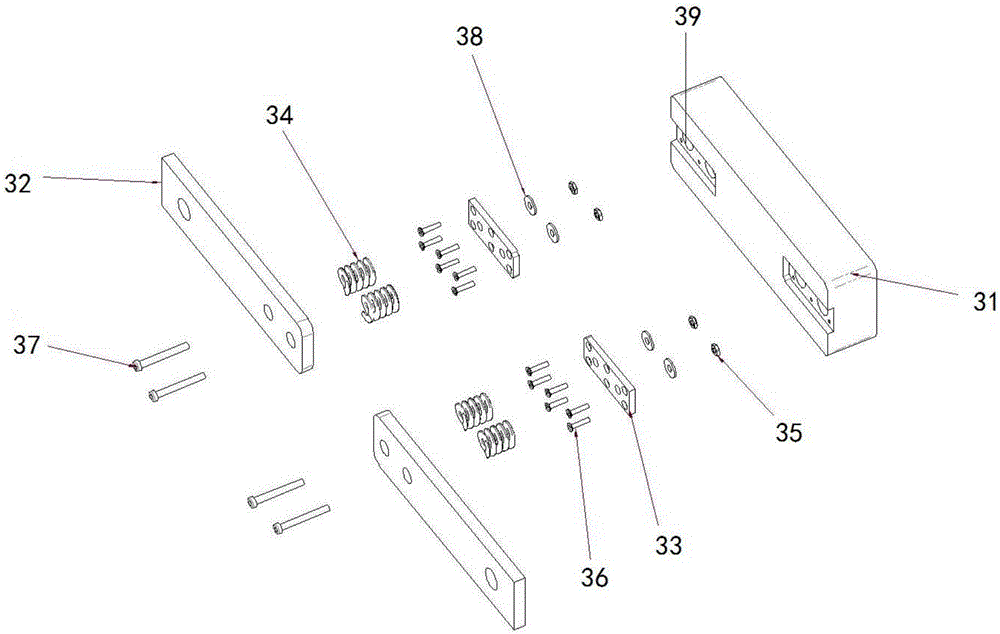

[0032] Such as Figure 1-6 As shown, a high-voltage current transformer primary wiring crimping device includes a steering mechanism, a crimping mechanism and a follower mechanism.

[0033] Such as Figure 5 As shown, the steering mechanism includes a rotary cylinder 111 and a rotary cylinder mounting base plate 14. The main body of the rotary cylinder 111 is fixed on the rotary cylinder mounting base plate 14, and a spacer 19 is arranged between the two. The spacer 19 is a square spacer and can be snapped into The groove on the rotary cylinder installation base plate 14 is connected with the rotary cylinder installation base plate 14 through connecting structures such as threaded connectors, and the main body of the rotary cylinder 111 is fixed on the spacer 19 by the rotary cylinder fixing screw 112 . The output shaft of the rotary cylinder 111 is parallel to the bottom plate 14 on which the rotary cylinder is installed.

[0034] Such as Figure 4 As shown, the crimping m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com