Combined method for repairing site soil through plant bionics, chemical leaching and microorganisms

A plant bionic and chemical leaching technology, applied in the field of soil remediation, can solve the problems that soil can only be used for construction, long remediation time and high cost, and achieves the effects of easy promotion and application, short remediation time and increased efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

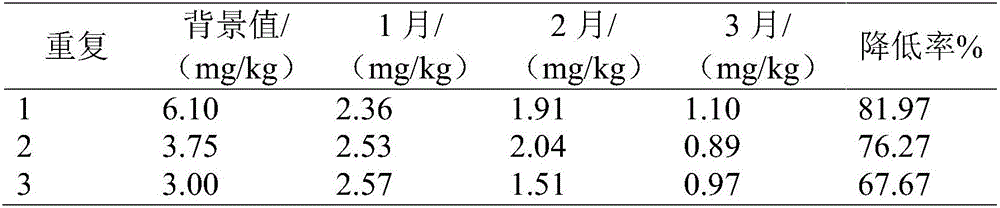

[0026] The test site is located in the abandoned chemical industry park in Zhuzhou, Hunan, the soil pH is 5.63, and the heavy metal Cd content is 6.25 mg·kg -1 , it has been determined that other heavy metals do not exceed the standard, so the target pollutant is the heavy metal Cd, and it is jointly repaired.

[0027] Experimental sampling was conducted to investigate the soil pollution status of the abandoned chemical industry park, to determine the spatial distribution map of heavy metal Cd, and to formulate a joint restoration plan in a targeted manner. The filler with good adsorption capacity for Cd is selected to make a plant bionic restoration device for bionic restoration of plants. At the same time, a leaching agent with a better leaching effect on Cd was selected for chemical leaching in combined restoration to change the existing form of Cd in the soil.

[0028] According to the test plan, the plant bionic restoration device was inserted, and the contaminated soil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com