Intermediate frequency furnace dust collection device

An intermediate frequency furnace, smoke and dust technology, applied in the direction of smoke and dust removal, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems that the smoke and dust collection cover cannot track and capture smoke and dust, cannot meet environmental protection requirements, and the dust removal effect is not ideal. Achieve the effect of simple structure, strong practicability and large transmission ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

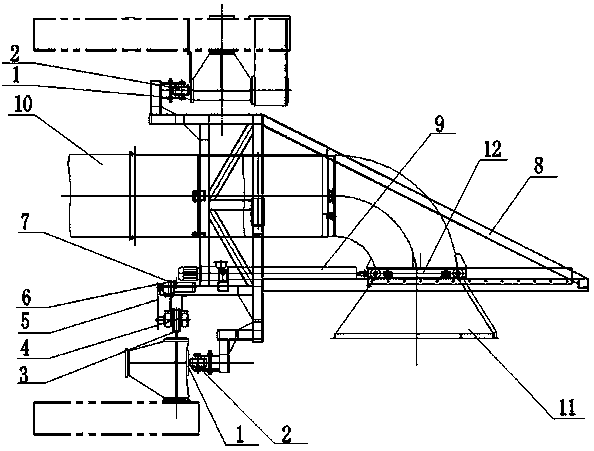

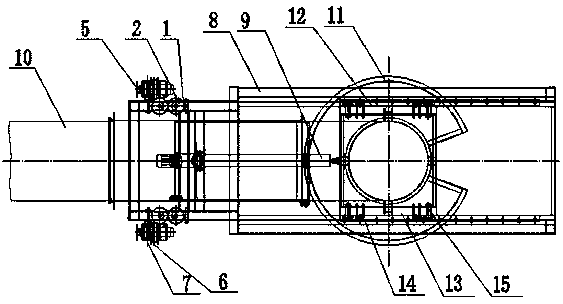

[0020] Such as figure 1 , figure 2 Shown is a dust collection device for an intermediate frequency furnace, which includes an umbrella-shaped top suction dust collection cover 11, the top of the dust collection cover 11 is connected to the front end of the dust pipe 10, and the rear end of the dust pipe 10 is connected to the bag type The dust collector and the blower are connected together, the top of the dust collection cover 11 is fixed on the horizontal telescopic traveling mechanism 12, and the horizontal telescopic traveling mechanism 12 walks on the longitudinal beam of the longitudinal traveling frame 8, and the horizontal telescopic traveling mechanism 12 and the electro-hydraulic push rod 9 The top end of the electro-hydraulic push rod 9 is fixed on the beam of the longitudinal walking frame 8; The wheel transmission mechanism 5 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com