Vibrating residue removal mechanism of split connecting rod bolt assembling facility

A technology for assembling equipment and cracking connecting rods, which is applied in the direction of cleaning methods and tools, chemical instruments and methods, etc., can solve problems affecting assembly accuracy and quality, and unclean slag removal, so as to improve assembly accuracy and quality, easy cleaning, Improves the effect of reset engagement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0031] In order to further illustrate the technical solution of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

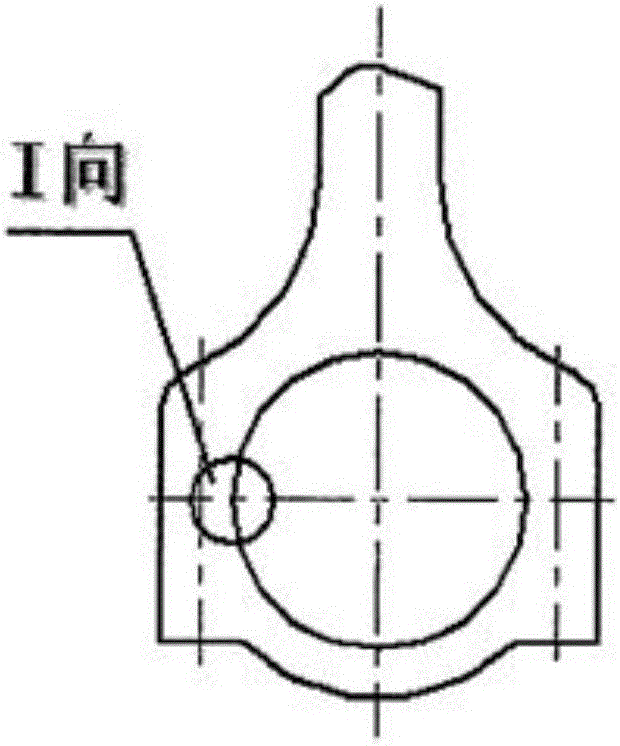

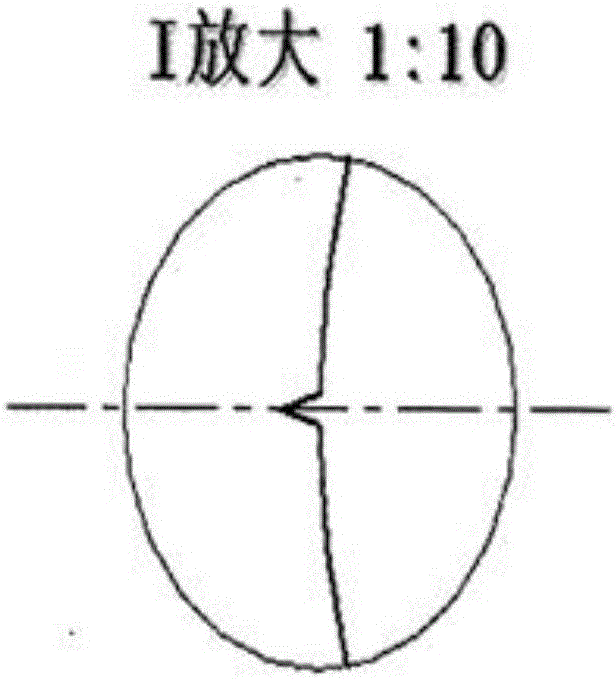

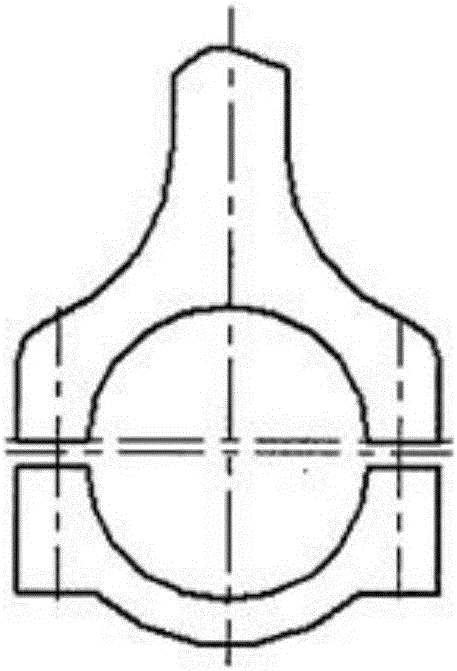

[0032] Such as Figures 1a-1d As shown, the connecting rod cracking process includes: a. pre-processing two cracking grooves in the big end hole of the connecting rod; b. breaking and dissecting the connecting rod; c. resetting and engaging the connecting rod cover and the connecting rod body. The present invention is aimed at the vibration slag removal link before the connecting rod cover and the connecting rod body are reset and engaged.

[0033] Such as Figure 2a-2c As shown, the present invention provides a vibratory slag removal mechanism for cracking connecting rod bolt assembly equipment. In order to more clearly illustrate the technical solution of the present invention, the following briefly describes other key components in the cracking connecting rod bolt assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com