Plate filter press

A plate-type filter press, plate-frame technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of high labor intensity and low efficiency, achieve improved work efficiency, wide application range, and reduce manual labor intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

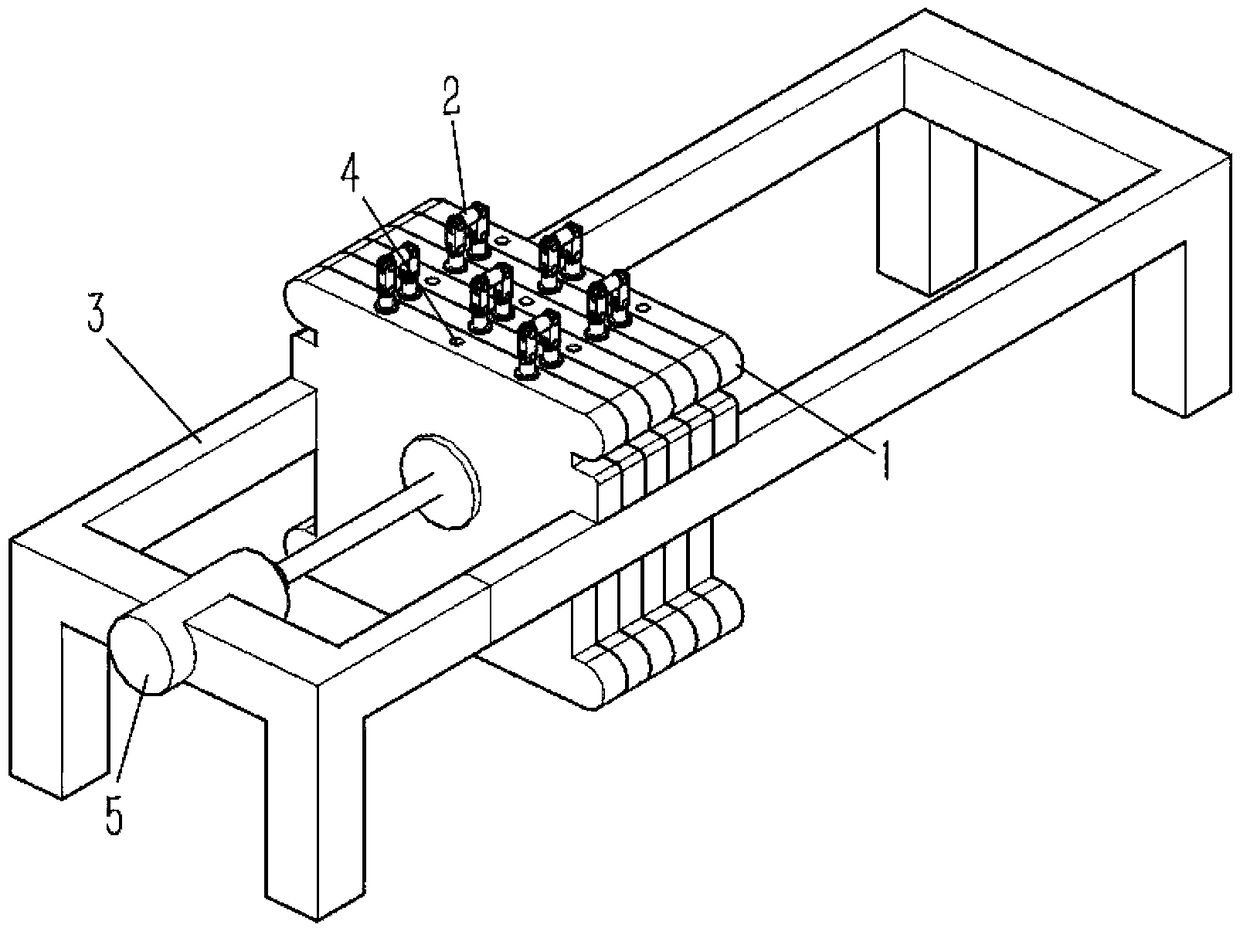

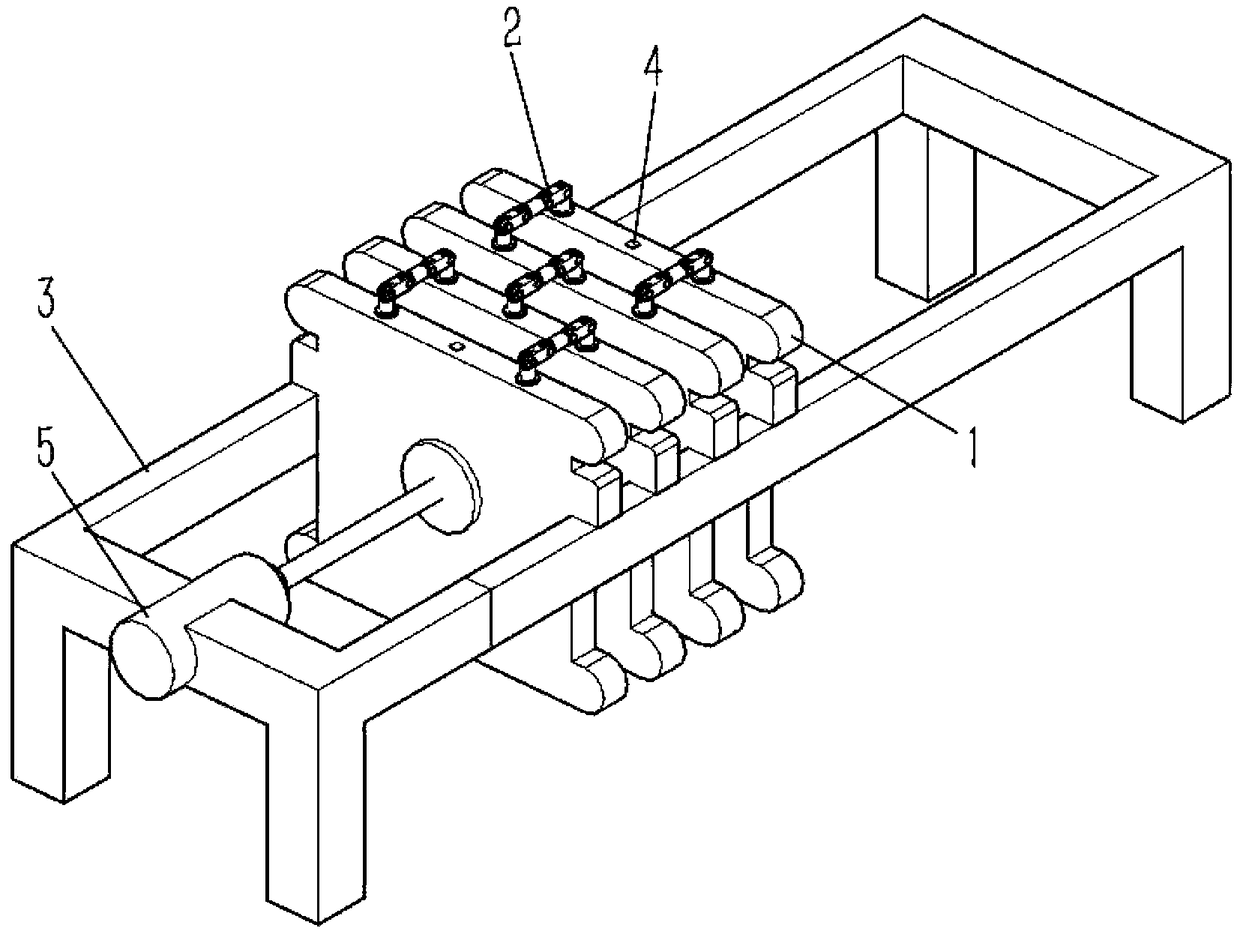

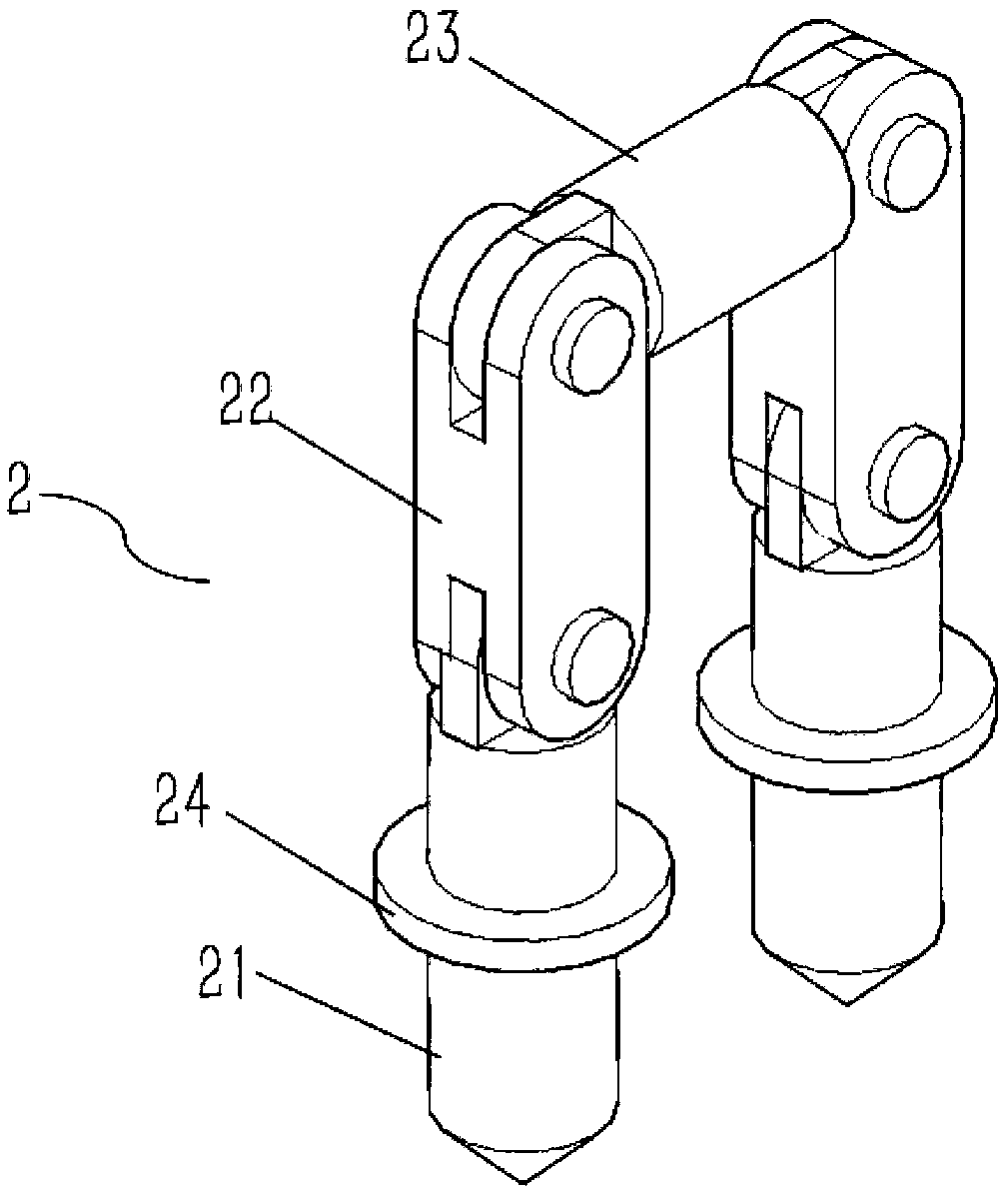

[0022] Such as Figure 1 to Figure 4 As shown, a plate filter press includes several plate frames 1 stacked in sequence along the horizontal direction, with protrusions on both sides of the plate frame 1, and guide rails 3 on the lower side of the protrusions of the plate frame 1, And the plate frame 1 can reciprocally slide on the guide rail 2; the center of the end of the guide rail 3 is provided with a hydraulic cylinder 5, and the telescopic direction of the hydraulic cylinder 5 is perpendicular to the surface of the plate frame 1; The upper side of the plate frame 1 is provided with a groove 4, and also includes a linkage device 2, and the linkage device 2 includes a positioning pin 21 and a linkage rod 23 arranged parallel to the vertical direction, and the upper end of the positioning pin 21 is provided with A rotating rod 22 is arranged, the lower end of the rotating rod 22 is hinged with the upper end of the positioning pin 21 , and the two ends of the linkage rod 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com